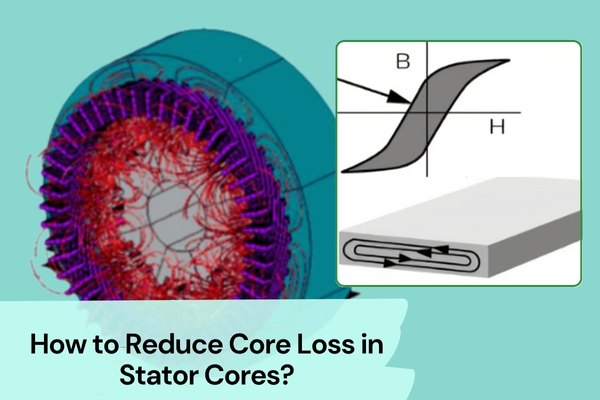

How to Reduce Core Loss in Stator Cores?

Motor overheating and low efficiency—what’s the real problem? If you work in motor design or deal with motors regularly, you may have noticed that sometimes, even when the winding and control system are perfectly fine, the motor still gets hot and its efficiency doesn’t improve. The problem often lies in one critical area—excessive core loss in the stator.