Amorphous Motor Core Laminations in China

As a leading manufacturer of amorphous motor laminations in China, we specialize in producing high-quality and customized laminations for electric motors.

Amorphous laminations are a crucial component in electric motors, as they determine the efficiency and performance of the motor. Unlike traditional silicon steel laminations, amorphous motor laminations are made from a unique alloy that has an irregular atomic structure, resulting in lower energy loss and higher magnetic properties. This translates into improved motor efficiency, reduced heat generation, and increased power output.

With our state-of-the-art facilities and experienced team, we have the expertise and capabilities to design and manufacture amorphous motor laminations that meet the specific requirements of our clients. Whether you need standard or customized laminations, we are committed to delivering superior-quality products that will enhance the performance of your electric motors.

Customize Amorphous Motor Laminations for Various Industries

Utilizing our advanced amorphous stator rotor core mass production line, we specialize in tailoring amorphous cores to meet diverse needs. Our customizable solutions extend to amorphous drive motors, high-speed motor shafts, and specialized cores for medical and military applications.

With a commitment to precision manufacturing, we offer a versatile range of options to cater to unique specifications. Whether it’s optimizing for efficiency, speed, or specific industry requirements, our expertise allows us to deliver bespoke amorphous motor cores, ensuring optimal performance in various electric motor applications.

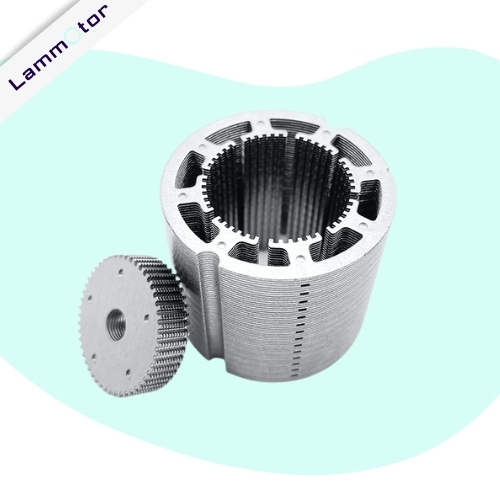

Amorphous Core for high speed motor/electric spindle

Amorphous stator Laminations for Vacuum Cleaners

Hub Amorphous Motor Laminations For New Energy Vehicles

Amorphous Motor Laminations for Air Conditioning Compressor

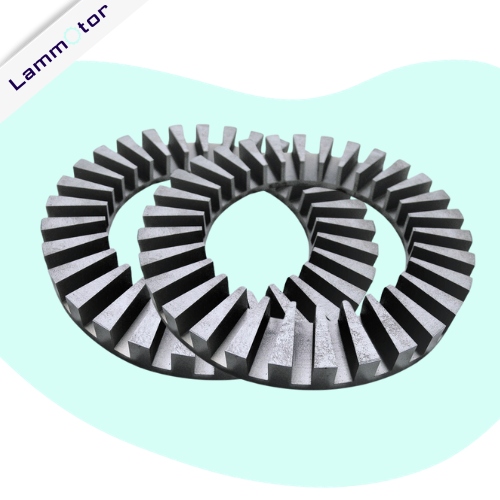

Axial amorphous motor lamination stacks

Amorphous stator core for drones and robots

Reluctance amorphous motor core

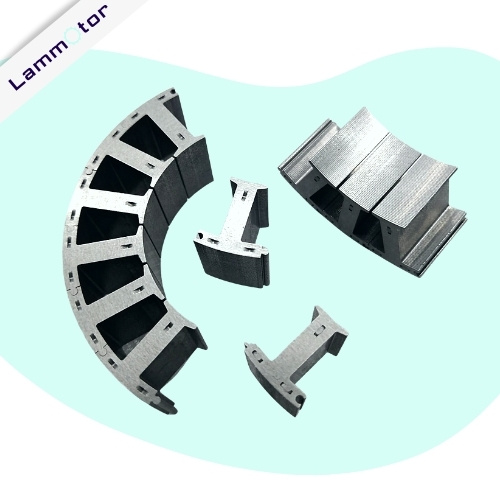

segmented Amorphous motor core

Power Tools Amorphous Stator

amorphous Core for treadmill

T-shaped amorphous core

Ring amorphous motor core

Wire EDM Amorphous Motor Core

We provide wire EDM to manufacture precision amorphous motor cores, ensuring unparalleled accuracy and customization. Using this cutting technique, we create intricate and complex shapes in amorphous materials with exceptional precision. The wire EDM process enables us to tailor amorphous motor cores to the exact specifications required for various applications.

Whether for high-speed motors, medical devices, or specialized industrial needs, our wire EDM amorphous motor cores exhibit superior quality, tight tolerances, and the reliability necessary for optimal motor performance. Trust us to deliver customized solutions that meet your unique requirements with precision and efficiency.

OUR SERVICES

Bonding for Amorphous Metal Motor Laminations

Our amorphous metal motor laminations undergo a meticulous bonding process, ensuring structural integrity and optimal performance.

We employ advanced adhesives and heat treatment methods to seamlessly bond amorphous metal laminations, creating a robust and cohesive core. This bonding ensures the integrity of the core structure, contributing to the overall efficiency and performance of the motor.

We provide amorphous metal motor laminations with superior bonding that meets the stringent standards of modern electric motor applications.

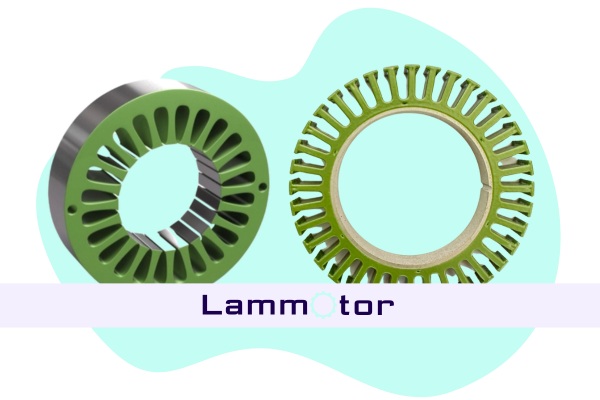

Electrostatic Epoxy Coating for Amorphous Electric Motor Laminations

Our amorphous electric motor laminations undergo a specialized electrostatic epoxy coating process, enhancing both performance and durability.

During this method, charged epoxy particles are attracted to the amorphous surface, creating a uniform and resilient coating. This process ensures complete coverage, even in intricate areas, providing excellent protection against corrosion and environmental factors.

The features of our electrostatic epoxy coating include superior adhesion, resistance to abrasion, and an even finish. This protective layer not only safeguards the laminations but also contributes to prolonged motor life and sustained efficiency, making it an ideal choice for demanding applications.

Amorphous Metal Stator Winding

We employ advanced techniques to intricately wind amorphous metal coils, enhancing the efficiency and performance of stators.

The unique non-crystalline structure of amorphous metals contributes to reduced energy losses, making them an ideal choice for stator windings.

This innovative approach ensures precise winding, allowing for optimal magnetic flux control and increased motor efficiency.

Elevate your motor technology with our amorphous metal stator winding, delivering reliability, energy savings, and enhanced performance for a wide range of applications.

OUR SERVICES

Quality Control for Amorphous Motor Cores

- Soft Magnetic Material Inspection: A rigorous examination of soft magnetic materials ensures they meet specified standards for optimal motor performance.

- CMM Utilization: Precision is paramount. CMM machines verify dimensional accuracy and adherence to tight tolerances.

- Performance Testing: Thorough testing assesses core functionality, efficiency, and reliability, ensuring the amorphous motor cores meet or exceed performance expectations.

- Inspection Reporting: A comprehensive inspection report is provided, detailing material quality, dimensional measurements, and performance metrics, offering transparency and confidence in the quality of our amorphous motor cores.

Advantages of Amorphous Alloy for Stator And Rotor Lamination Stacks

- Rapid Solidification: The unique preparation process involves rapid solidification, ensuring a non-crystalline structure. This enhances the material’s properties, contributing to improved motor efficiency.

- Long-Range Disorder of Atomic Structure: The amorphous structure features long-range disorder in atomic arrangement, enhancing magnetic properties. This disorder contributes to reduced hysteresis losses, promoting energy conservation.

- Excellent Soft Magnetic Properties: Amorphous cores exhibit exceptional soft magnetic characteristics, minimizing energy dissipation as heat. This property is vital for achieving higher energy efficiency in electric motors.

- Low Iron Loss: Amorphous motor laminations experience significantly lower iron losses compared to traditional crystalline counterparts. This translates to reduced energy waste and increased overall motor efficiency.

- Energy Efficient: The combination of rapid solidification, unique atomic structure, and soft magnetic properties results in an energy-efficient solution. Amorphous cores contribute to lower energy consumption and operational costs in electric motors.

- High-Frequency Characteristics: Amorphous materials excel at high frequencies, making them suitable for motors operating in variable-speed drives and other applications where high-frequency performance is crucial.

- High Permeability: The amorphous structure enhances permeability, allowing for effective magnetic flux control. This property is instrumental in optimizing motor performance and responsiveness.

- High Magnetic Density: Amorphous cores can achieve high magnetic density, contributing to stronger magnetic fields within the motor. This characteristic enhances the overall power and performance of electric motors, particularly in demanding applications.

Other Products

FAQs

Amorphous metal, also known as metallic glass or glassy metal, is an alloy that lacks a crystalline structure typically associated with metals. Instead, it has a disordered, non-crystalline atomic structure.

This unique atomic arrangement is achieved through rapid cooling or solidification of the molten metal, preventing the atoms from forming a regular crystalline lattice.

The absence of a crystal structure imparts distinctive properties to amorphous metals, such as high strength, hardness, and corrosion resistance.

They often exhibit excellent magnetic and electrical properties, making them valuable in applications such as transformer cores, magnetic sensors, and high-performance motors.

Amorphous metals are also known for their unique combination of mechanical and magnetic characteristics, contributing to advancements in various technological fields.

Yes, our manufacturing process allows for the customization of amorphous laminations, catering to different motor sizes, shapes, and specifications to meet diverse industry needs.

Amorphous motor laminations differ from silicon steel laminations primarily in their atomic structure. While electrical steel has a crystalline structure, amorphous motor laminations are made from non-crystalline metal alloys.

This distinction results in unique properties for amorphous laminations, including reduced core losses, improved energy efficiency, and enhanced magnetic characteristics.

Amorphous laminations are particularly advantageous in applications where minimizing energy losses and optimizing motor performance are crucial, setting them apart from traditional silicon steel laminations.

Absolutely. Amorphous laminations find applications in various motor types, from residential appliances to industrial machinery, thanks to their versatility, energy efficiency, and excellent magnetic properties.

Looking for an Amorphous Motor Laminations China Manufacturer?

Elevate your electric motors with our precision-crafted amorphous motor laminations. As a leading manufacturer in China, we offer tailored solutions for enhanced efficiency and optimal performance. Whether you need customized designs or industry-standard laminations, our expertise ensures top-tier quality.

Don’t compromise on energy efficiency—partner with us for cutting-edge amorphous motor laminations. Contact us now to discuss your requirements, explore customization options, and secure high-performance laminations for your electric motors. Trust in our commitment to excellence and innovation. Your satisfaction is our priority. Let’s shape the future of motor technology together!