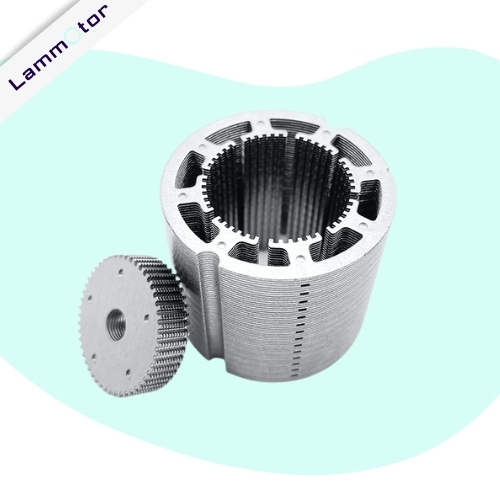

BLDC motor Lamination Stacks

As a leading China manufacturer of BLDC motor lamination stacks, we offer customized solutions for lamination stacks that meet the customer’s specific requirements. Stator and rotor lamination stacks are essential components of a BLDC (brushless DC) motor, which converts electrical energy into mechanical energy.

Our lamination stacks are made from high-quality electrical steel materials and provide maximum efficiency, reliability, and performance. We use advanced manufacturing processes to ensure precision and consistency in our products, and we work closely with our customers to deliver personalized solutions that match their needs. We produce high-quality electrical steel lamination stacks that help our customers achieve better motor performance and lower costs.

Stamping lamination stacks for BLDC motors

We use advanced stamping equipment to produce high-quality electrical steel lamination stacks for BLDC motors. Our stamping process allows us to create precise designs with minimal material waste, resulting in a cost-effective solution for our customers.

We can customize the stack size, number of teeth, and thickness to match each motor’s unique specifications. Our experienced team ensures that each lamination stack is accurately stamped to provide maximum efficiency and performance.

By utilizing our stamping services, our customers benefit from high-quality, reliable products that help maximize the potential of their BLDC motors.

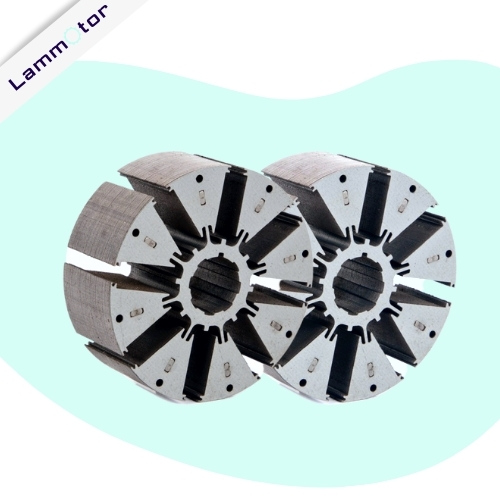

Customized Stator And Rotor Lamination Stacks For BLDC Motor Cores

We offer a range of options for customizing stator laminations and rotor laminations for BLDC motor cores. We can create Solt 6 brushless motor stator and Solt 12 brushless motor stator designs for industrial motors, as well as other variations based on customer requirements.

And we are specializing in the design and manufacturing of high-precision stamping laminations, such as the motor rotor and stator. They are widely suitable in electronics, generators, instruments, auto parts, industrial, household items, etc. Our abilities include punching, laser cutting, and wire EDM machining.

BLDC Motor Stator Winding

For BLDC motor stator winding, we offer both manual and automated winding solutions.

For prototype samples, we provide manual winding, ensuring flexibility and precision for custom designs.

For large-scale production, we utilize automated winding machines, which increase efficiency and consistency while maintaining high-quality standards.

OUR SERVICES

Why choose us aS your BLDC Motor laminations China Manufacturer?

When it comes to BLDC motor lamination stacks, customers can trust us to deliver the highest quality products, personalized service, and expert support throughout the process. Our lamination stacks are designed for optimal motor performance, delivering high speeds or high torque as required. There are several reasons why customers should choose us as their BLDC motor lamination China manufacturer.

Quality

We use advanced stamping technology and materials to ensure that our products are of the highest quality and meet industry standards.

Service

We pride ourselves on providing exceptional customer service, with a focus on meeting deadlines and exceeding expectations.

Customization

We offer a range of customization options to ensure that each lamination stack meets the specific requirements of the project.

lamination stacks for other motors

In addition to BLDC motor lamination stacks, we also specialize in customizing stator and rotor lamination stacks for various types of motors.

We understand that different motors require unique designs to achieve optimal performance. We work closely with our customers to develop customized solutions that meet their specific needs.

From induction motors to synchronous motors, we have the knowledge and experience to produce high-quality stator and rotor lamination stacks that deliver efficient, reliable performance.

BLDC Motor core lamination FAQs

What is a BLDC motor lamination stack?

A BLDC motor lamination stack is a core component of a brushless DC electric motor.

It consists of thin silicon steel laminations of magnetic material arranged in a specific pattern to create an efficient and reliable motor.

What materials are used to make BLDC motor lamination stacks?

The most common materials used for BLDC motor lamination stacks are silicon steel and amorphous metal alloys.

These materials have high magnetic permeability and low core loss, making them ideal for use in motor components.

How do you determine the optimal lamination stack design for a BLDC motor?

The optimal lamination stack design for a BLDC motor depends on various factors such as motor size, operating conditions, and desired performance characteristics.

Our team of experts uses advanced software and simulations to develop customized solutions that meet our customers’ specific requirements.

What is the maximum outside diameter of the BLDC motor lamination stacks we produce?

We manufacture laminates with a maximum outside diameter of 420mm for generating motors.

In general, the diameter of BLDC motor lamination stacks depends on several factors, including the thickness of the laminations, the size of the motor, and the desired performance characteristics.

Typically, we can produce lamination stacks ranging from 16mm to 260mm in diameter, with larger diameters being more common for industrial and heavy-duty applications.

Let’s get started on your lamination stacks project!

Looking to take your projects to the next level with high-quality BLDC motor lamination stacks? Look no further! We are here to provide you with the best quality lamination stacks that meet your exact specifications. With years of experience in the industry, we understand the unique needs and requirements of our customers and deliver top-notch solutions that exceed expectations.

So don’t wait any longer, contact us today to discuss your project requirements and get started on your journey toward success. Let us help you take your projects to the next level with our high-quality BLDC motor lamination stacks. Get in touch with us now and see the difference!