Motor Lamination Stacks for Water Pumps in China

Welcome to Lammotor, the premier water pump motor lamination manufacturer in China. We specialize in crafting lamination stacks that elevate pump motor performance. Our laminations are meticulously designed to optimize efficiency, ensuring seamless operation in various industrial motors.

With cutting-edge manufacturing capabilities, we pride ourselves on precision laser cutting, stamping, and customization, meeting the diverse needs of our clients.

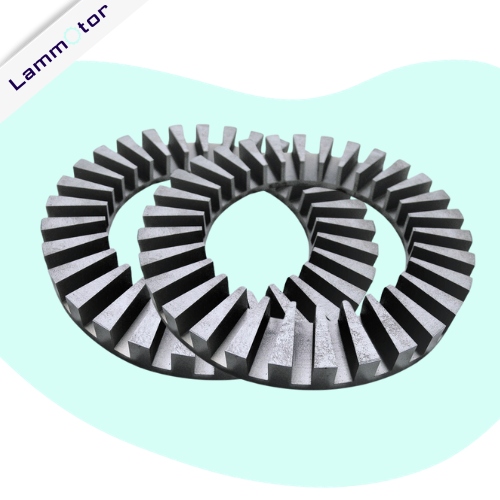

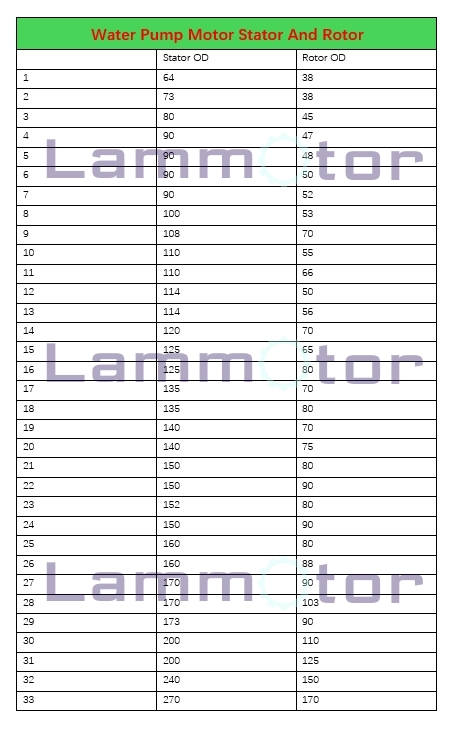

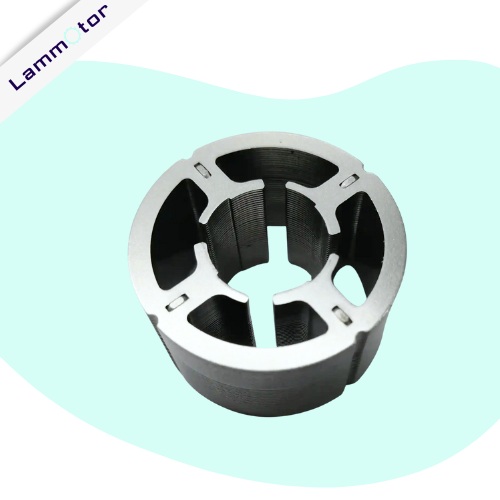

Public Mold of Pump Motor Laminations

We have a range of molds for the production of industrial motors, pump motors, blower motors, sawmill motor stators and rotors. The stator diameter ranges from 64mm to 270mm, and the rotor diameter ranges from 38mm to 170mm.

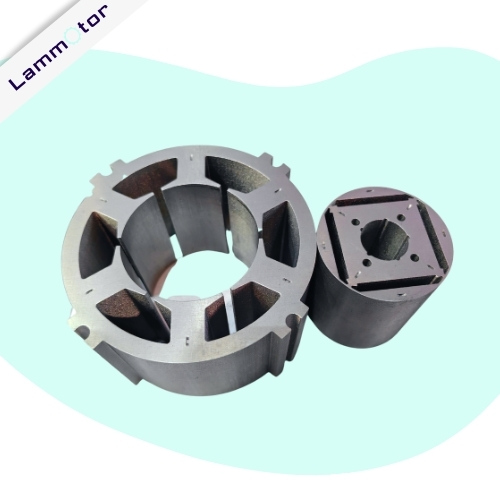

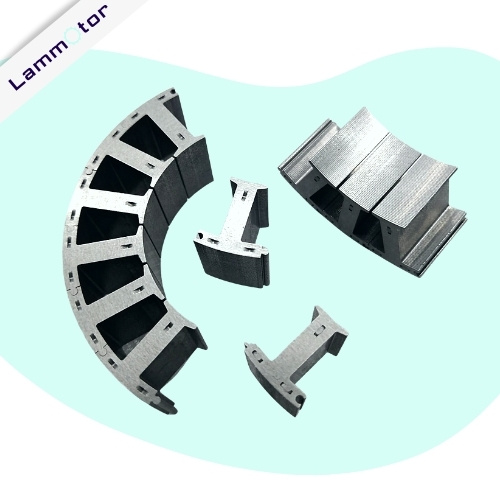

Customize Motor Laminations for Pumps

As specialists in customized electric motor laminations for pumps, we can customize stator rotor lamination stacks for various pump types. Such as compressed water pump motors, industrial pump motors, and submersible pumps.

Our expertise lies in offering unmatched flexibility, allowing customization in design, size, and material choices to meet the unique requirements of each client.

Whether it’s optimizing efficiency, ensuring durability, or meeting specific industry standards, we excel in delivering precision pump laminations that elevate pump motor performance.

Water Pump Motor Stator and Rotor

Water Pump Motor Skew Rotor

DC Water Pump Motor Core

Submersible Pump Motor Core

Automobile Water Pump Motor Stator

Water Pump Die Cast Skew Rotor Core

Water Pump Motor Die Cast Rotor Core

Miniature Water Pump Motor Core

Pump Motor Laminations Manufacturing Process

The pump motor core manufacturing process involves a series of meticulous steps to ensure optimal performance.

Progressive Stamping: Utilizing precision machinery to stamp out electrical steel laminations in a progressive manner.

Stacking: Assembling laminations through interlocking and welding methods to create a sturdy core structure.

Rotor Aluminum Casting: Crafting the rotor component through aluminum casting, ensuring durability and efficient heat dissipation.

Stator Winding: Precision winding of the stator with copper coils, is a crucial step in creating the electromagnetic field for motor operation.

Each step is crucial in achieving a high-quality pump motor, balancing efficiency and durability in the manufacturing process.

OUR SERVICES

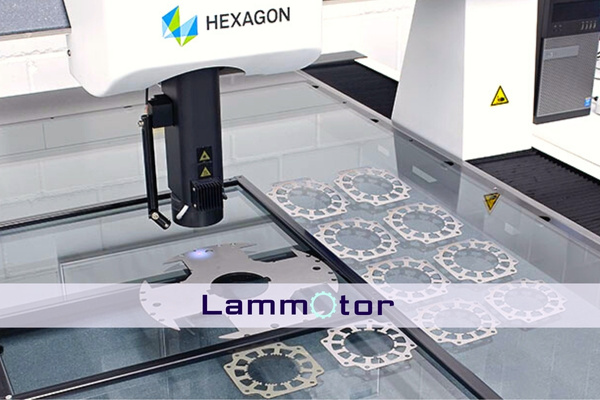

Quality Control for Pump Motor Stator and Rotor Laminations

We employ advanced inspection techniques at every stage to ensure uncompromised quality. Starting with material testing, we verify the integrity of silicon steel laminations. Precision measurements and visual inspections follow during the progressive stamping and stacking phases, guaranteeing accuracy and durability.

The rotor aluminum casting undergoes meticulous scrutiny for material composition and structural soundness. Our dedicated team conducts comprehensive tests on stator windings, assessing insulation and connectivity.

Final inspections involve thorough dimensional checks and visual examinations, assuring that every lamination meets our stringent standards.

Other Products

FAQs

In the manufacturing of pump motor laminations, we prioritize high-quality materials to ensure optimal performance. The primary material utilized is silicon steel, renowned for its magnetic properties and ability to reduce energy losses.

Silicon steel laminations provide the necessary core structure for efficient electromagnetic functioning within the motor. This choice of material enhances the overall durability and performance of the laminations, making them ideal for various pump applications.

Our pump motor laminations find applications across diverse industries due to their versatility and high performance. Common sectors include:

Water Management: Used in water pumps for irrigation, municipal water supply, and wastewater treatment.

Oil & Gas: Employed in pumps for oil extraction, refining, and transportation processes.

Industrial Manufacturing: Integral in various manufacturing processes requiring pumping systems.

HVAC Systems: Utilized in heating, ventilation, and air conditioning units for efficient airflow.

Renewable Energy: Incorporated into pumps for solar and wind energy applications.

Automotive: Applied in automotive water pumps and coolant circulation systems.

At Lammotor, our pump motor laminations cater to the diverse needs of these industries, ensuring reliable and efficient operation.

Certainly! At Lammotor, customization is our expertise. We specialize in tailoring laminations to meet the specific requirements of various pump models.

Our skilled team ensures flexibility in design, size, and material choices to optimize performance.

Whether you have unique specifications or industry-specific needs, we are dedicated to delivering customized pump motor laminations that perfectly align with your pump models.

Looking For A Pump Motor Laminations China Manufacturer?

Ready to elevate your pump motor performance? Look no further! Lammotor stands as a leading pump motor laminations China manufacturer, offering top-notch customization and precision manufacturing. Benefit from our expertise and motor core manufacturing technology to enhance the efficiency and durability of your pump motors.

Whether you require tailored solutions or industry-standard motor stator laminations, we have you covered. Reach out today for a quote and experience the difference with us – your trusted partner in pump motor lamination stacks manufacturing excellence.