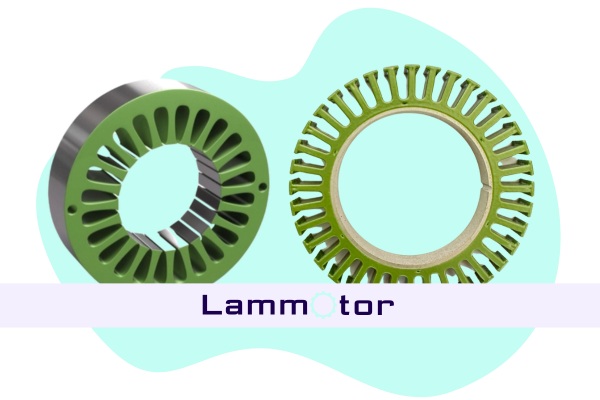

Electrostatic Epoxy Coating Insulation for Motor Core

Motor cores play a crucial role in the efficient functioning of electric motors. To enhance their durability and performance, we provide various coating methods. One such method gaining popularity is electrostatic epoxy coating. We have an automatic electrostatic epoxy coating line that allows the insulation of iron laminate cores.

Electrostatic Motor Epoxy Powder Coating

Electrostatic epoxy coating is a process in which an electrically charged powder is applied to the surface of a motor core. The powder is attracted to the core due to the electrostatic charge and evenly coats the surface.

Powder coating offers a seamless, non-conductive protective layer that is highly resistant to chemicals and heat, safeguarding motor coil windings effectively. In terms of both performance and cost, epoxy coating for stators is generally more advantageous than traditional insulation methods like paper or plastic over-molding.

This coating technique not only streamlines the motor winding process but also facilitates the automation of motor assembly. Consequently, it has become increasingly popular in the manufacturing of Brushless DC (BLDC) motors and Slotless Motors.

specifications of powder coating

- Temperature Class: B,F,H

- Coating Thickness: 0.15-0.6mm, customized with voltage requirement and stator dimension

- Voltage Resistance: TBD

- Color: Blue, Green

- Stator Dimension: Max 350mm

3M Series Epoxy Powder Spec.

| Material Model | Temperature Class | Color | Certificates |

| 3M860 Series | F Class (155℃) | Blue, Green | ROHS |

| 3M266 | F Class (155℃) | Blue, Green | UL, ROHS |

| 3M260, 3M555, 3M5230N | H Class (180℃) | Blue, Green | UL, ROHS |

Typical Process Of Motor Stator Rotor Insulation Coating

The typical process of motor core insulation coating involves several steps to ensure effective and reliable insulation for the stator.

Step 1: the motor laminations are manufactured through stamping or welding processes.

Step 2: a fixture for insulation coating is designed and manufactured based on the stator powder coating drawing. The coating specifications are inputted into the computer of the electrostatic electrical insulation coating machine.

Step 3: The stator undergoes the epoxy coating process, and inspections are conducted to ensure proper coating application.

Step 4: After the coating process, the stator is subjected to hardening or baking in an oven at a defined temperature. Once hardened, the stator is cooled down to ambient temperature.

Step 5: a thorough inspection is performed to verify the quality and effectiveness of the completed motor stator epoxy coating products.

Our Advantages

At our company, we take pride in offering top-notch electrostatic epoxy coating insulation services for motor cores.

- Our coatings can meet the highest industry standards and cater to various temperature classes, including B, F, and H.

- We offer a range of options from 0.15mm to 0.6mm coating thickness to ensure optimal performance.

- Our coatings can be customized according to your voltage requirements and the dimensions of your motor stator and rotor.

- We provide two color options for electrostatic epoxy coatings: blue and green.

- Additionally, our coating services are suitable for stators with dimensions of up to 350mm. And we provide motor stator winding services.

Applications Of Epoxy Powder Coating Motor Core

Epoxy powder coating is suitable for a wide range of motor cores. The coating provides excellent insulation properties and helps to protect the motor core from moisture, dust, and other contaminants.

It is commonly used in applications where electrical insulation is critical, such as in electric motors used in appliances, automotive components, industrial equipment, and electronics.

Epoxy powder coating forms a durable and uniform protective layer that improves the motor’s performance, extends its lifespan, and enhances its resistance to corrosion and mechanical stress.

Its ability to adhere to various substrates makes it a versatile choice for different types of motor cores, ensuring optimal electrical insulation and reliable operation.

Epoxy Powder Coating FAQs

Motor cores, typically made of laminated steel sheets, form the foundation of electric motors. These cores are subjected to various stresses during operation, including mechanical, thermal, and environmental factors.

To protect motor cores and enhance their longevity, different coating techniques are employed. Electrostatic epoxy coating is one such method that provides several advantages over traditional coating methods.

Yes, electrostatic epoxy coatings have excellent thermal stability and can withstand elevated temperatures typically encountered in motor operation.

Corrosion Resistance

One of the primary benefits of electrostatic epoxy coating is its exceptional resistance to corrosion. Motor cores are often exposed to moisture, chemicals, and other corrosive agents. The epoxy coating forms a protective barrier, preventing the core from direct contact with these elements and safeguarding it against rust and corrosion.

Improved Insulation

Motor cores require efficient electrical insulation to prevent short circuits and ensure optimal performance. Electrostatic epoxy coating provides excellent insulation properties, reducing the risk of electrical breakdown and enhancing the overall insulation system of the motor.

Thermal Stability

Electric motors generate heat during operation, and excessive heat can degrade the performance of motor cores. Electrostatic epoxy coatings have high-temperature resistance, allowing them to withstand elevated temperatures without deforming or losing their protective properties. This improves the motor core’s thermal stability and prolongs its lifespan.

Electrostatic epoxy coating is compatible with most motor core materials, including steel and iron. However, it is recommended to consult with coating experts to determine the most suitable formulation for specific core materials.

To find reliable suppliers of electrostatic epoxy coatings, you can explore industry directories, consult coating specialists, or search online for reputable manufacturers and distributors.

Contact Us for Electrostatic Motor Epoxy Powder Coating

Are you in need of professional motor core epoxy coating services? Look no further! Our experienced team specializes in providing high-quality insulation coatings for motor cores. Don’t compromise on the performance and longevity of your electric motors. Contact us today to discuss your requirements, receive a personalized quote, and benefit from our exceptional services.