Motor Laminations For Power Tools In China

As a leading power tools motor laminations manufacturer in China, we understand the significance of high-quality laminations in electric power tool motors. Electric power tool laminations are essential components that help improve the performance and efficiency of power tools. They play a crucial role in reducing energy loss and improving the overall functionality of the motor.

Whether you’re building a lawn mower or pruning shears, your motor must run flawlessly. At Lammotor, we specialize in the design and manufacture of electrical steel laminations for power tools to meet the most demanding requirements of brushed and brushless motors. We help you create the perfect motor lamination to meet your needs and ensure your power hand tools perform optimally.

Customize Electrical Steel Laminations for Power Tools

Elevate the performance of your power tools with our tailored electrical steel laminations. We specialize in crafting precision-engineered laminations designed to meet the unique requirements of power tools.

Our motor lamination products are widely used in electric drills, angle grinders, electric paint sprayers, chainsaws, electric shavers, blenders, lawnmowers, and pruners.

Our customization process allows for meticulous adjustments in dimensions, materials, and coatings, ensuring optimal efficiency and durability. We leverage advanced stamping technology and high-quality silicon steel to create lamination stacks that enhance the overall functionality of power tools.

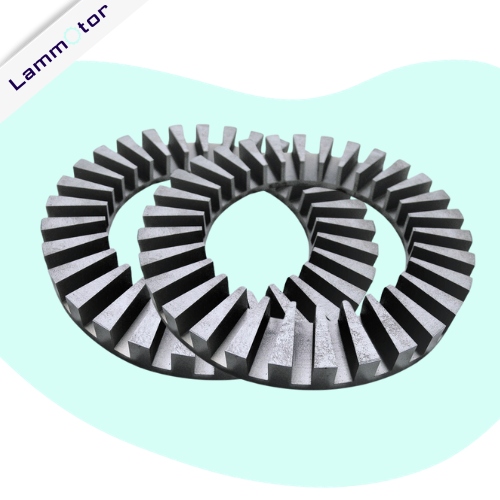

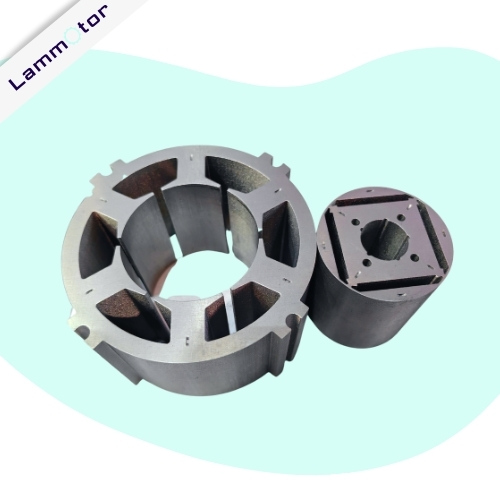

Electric Power Tools Motor Stator And Rotor

Power Tools Amorphous Stator

electric mixer motor Lamination Stacks

electric blower stator laminations

Stator Rotor Lamination Stacks Manufacturing Process For Power Tools

Prototyping: Utilizing advanced techniques such as laser cutting or wire EDM to create initial prototypes for precise design validation.

Progressive Stamping: Employing progressive stamping methods to efficiently and precisely cut and shape laminations from high-quality materials like silicon steel.

Stacking (Interlocking): Assembling laminations in a carefully interlocked manner ensures a secure and robust stacking process that forms the foundation for the stator and rotor assembly.

Stator Winding: Incorporating stator winding is a critical step where the copper wire is strategically wound around the stator lamination stacks to create the necessary electromagnetic fields for optimal motor function.

Electrostatic Epoxy Coating: Applying an electrostatic epoxy coating to the laminations to enhance insulation, durability, and resistance to environmental factors, contributes to the overall longevity and performance of the stator rotor lamination stacks.

OUR SERVICES

Quality Control for Power Tools Motor Laminations

Our commitment to delivering high-quality silicon steel laminations is upheld through rigorous quality control measures. Tolerances are maintained at an impressive (+/-) 0.0001 inches, ensuring precision at every stage of manufacturing.

To achieve this level of accuracy, our state-of-the-art equipment includes an Optical Measuring Machine and a Coordinate Measuring Machine. These tools enable meticulous inspections, guaranteeing that each power tools motor lamination meets the exacting standards required for optimal performance.

From material selection to the final product, our quality control processes are designed to exceed industry expectations, ensuring that every motor stator rotor leaving our facility is of the highest quality and consistency.

Other Products

FAQs

Power Tools Motor Laminations are predominantly crafted from high-quality silicon steel.

This material is chosen for its exceptional magnetic properties, contributing to enhanced efficiency and performance in power tool applications.

Other materials are cobalt alloys, nickel alloys, and amorphous metals.

Absolutely. Our motor laminations are engineered to withstand high temperatures encountered in power tool applications. Using advanced materials, we ensure thermal stability, preventing deformation or degradation.

This design feature ensures reliable performance, even in demanding conditions, making our laminations ideal for power tools operating in elevated temperature environments.

Customized dimensions play a crucial role in power tool performance. Tailoring laminations to specific dimensions ensures an optimal fit, reducing energy loss and improving overall efficiency.

Precision in dimension customization contributes to enhanced power transfer, and reduced vibrations, and ultimately results in power tools that operate with heightened effectiveness and longevity.

Yes, we provide a range of coating options specifically designed for corrosion resistance.

Our coatings not only protect the motor laminations from environmental elements but also enhance their durability.

This ensures that our power tools motor laminations maintain optimal performance over an extended lifespan, even in challenging operating conditions.

Looking for an Electric Power Tools Motor Laminations Manufacturer in China?

Discover excellence in industrial motor laminations with us. As a leading manufacturer, we specialize in crafting customized solutions that elevate the performance of your electric power tools. Benefit from our precision engineering, high-quality materials, and advanced manufacturing processes.

Whether you need tailored dimensions, enhanced efficiency, or noise-reduction technology, we have you covered. Choose reliability, choose innovation – choose us for your power tools motor lamination needs. Contact us today to discuss your requirements and experience the difference in quality that sets us apart as your trusted partner in China.