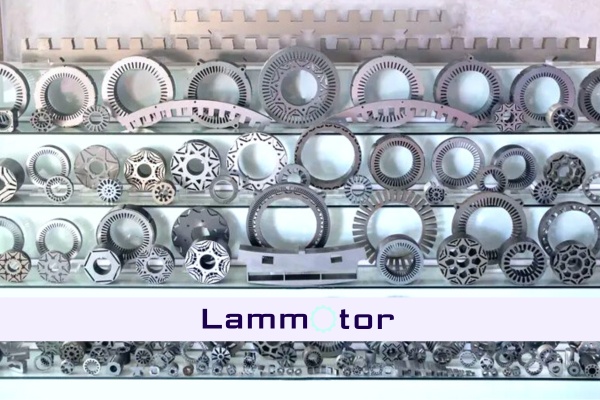

Motor Bonding Lamination Stacks

In motor lamination stack manufacturing, glue bonding stator and rotor stand out as a pivotal technique, ensuring enhanced durability and precision. This method not only elevates the efficiency of motors but also guarantees longevity. At Lammotor, we pride ourselves on mastering this intricate process. With years of hands-on experience and a dedicated team of experts, we’ve established ourselves as industry leaders in bonding lamination stacks for stator and rotor assemblies. Trust in our expertise to deliver unparalleled quality and precision.

Bonding Lamination Stacks Technology Without any Interlock Point or Welding

The eddy current loss of the stator and rotor is an unavoidable problem in motor design. High-performance and high-speed motors are more sensitive to iron losses and motor efficiency, so how to reduce their iron losses has become a major consideration.

In addition to choosing thinner silicon steel sheets, we also use stator and rotor bonding lamination stacks technology. Because traditional riveting self-fastening and welding cannot fundamentally prevent the interlayer conduction of this silicon steel sheet.

We specialize in motor lamination bonding! We stand out in the market with our extensive in-house resources, including a specialized engineering team, a professional welding crew, cutting-edge production plants, and a dedicated quality assurance division.

Our expert technicians are adept at various welding techniques, including MIG, TIG, YAG, spot, laser, and CNC robotic welding. Additionally, we offer a range of bonding methods for your core assembly, such as staking, skewing, tabbing, and riveting.

Bonding Lamination Stacks for Prototyping

When it comes to prototyping in the electrical motor and transformer manufacturing industry, bonding lamination stacks is a critical step that can significantly influence the performance and feasibility of the final product.

Prototyping does not typically require the volume of production that mass manufacturing does, allowing for more manual or semi-automated bonding processes.

The adhesive is applied with precision to ensure that each layer of the lamination stack bonds correctly without excess or insufficient adhesive. This may be done by hand or with precision equipment, depending on the complexity and size of the prototype.

Materials of Bonding Stack laminations

| EB540, EB546, EB548 | EB540, EB546, EB548 are mainly used in large motor cores for rail transportation, wind power, etc |

| EB549 | EB549 is mainly used in small and medium-sized motor cores for electric vehicle drive motors and so on. |

| Magna-Tac E645 | Magna-Tac E645 stands as the go-to epoxy in the Electric Motor Industry. The bonding adhesive is suitable for a diverse range of components such as stators, rotors, gyros, servomechanisms, synchros, transformers, and magnetic amplifiers. |

| Magna-Tac F310 | Magna-Tac F310 is known for its high-temperature resistance and strong bonding capabilities. It is designed to maintain its adhesive properties in extreme conditions, ensuring that the lamination stack remains intact even in the most demanding of environments. |

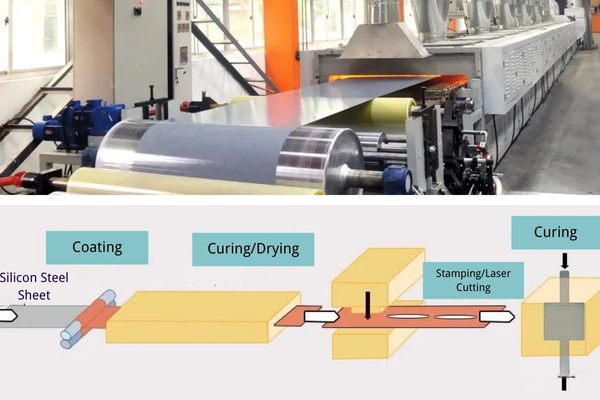

Self-bonding coatings and motor lamination stacks Bonding Technology

The self-bonding coating program is an emerging method of lamination stacks. The self-bonding coating belongs to the ASTMA976 classification of organic resin coating type C3, and its coating principle and processing method are shown in the figure.

A self-bonding coating solution is applied on both sides of the electrical steel substrate, which is heated and baked in the production line to form an incompletely hardened semi-finished product.

This semi-finished product is rolled, slit, stamped, stacked, and fixed with clamps in the production line, and then heated and pressurized for curing.

The cured and bonded motor core avoids the stresses and changes in iron loss caused by welding and riveting of electrical steel, improves the motor’s overall performance, and reduces the vibration and noise generated by the rotation of the core. Therefore, self-bonding electrical steel is very suitable for high-frequency and high-speed motors.

Typical process of Motor bonding Lamination

We apply high-temperature Glue/Epoxy Adhesive on the stators to glue the stator sheet together and ensure they will not be lost. It does not need any interlock point and welding so it can lower the iron loss to a maximum level. Here’s a breakdown of each step:

Punching or Wire Cutting Silicon Steel Sheets

The process begins with shaping the silicon steel sheet. This can be achieved through punching, which efficiently stamps out the desired shape, or EDM wire cutting, a precise method that uses electrical discharges to cut the silicon steel sheet.

Cleaning

Once shaped, the sheet undergoes a thorough cleaning to remove any burrs or debris. This step is crucial to ensure a smooth surface, essential for the subsequent bonding process.

Designing the Lamination Fixture

A specialized lamination fixture is designed to hold the sheets in place. This fixture is tailored to accommodate the specific geometry of the stator, ensuring that the sheets are aligned correctly during the bonding phase.

Bonding

The sheets are then bonded together using high-temperature glue or epoxy. The adhesive is applied, and the sheets are stacked to the designed stator height, ensuring uniformity and strength in the bond.

Baking

After bonding lamination stacks, the stator is baked. This step is critical as it cures the glue, solidifying the bond. The baking is done at least twice to ensure the glue is completely hardened and the bond is secure.

Inspection

The final step is a comprehensive inspection. This quality control measure checks for any defects in the bonding process, ensuring that the stator meets all the required specifications and standards for performance and safety.

Applications of Glue Bonding Lamination Stacks

This method proves indispensable for thin metal sheet laminate products, which are paramount in crafting motor cores for hybrid car drives. These high-efficiency motor cores, made possible through glue bonding, are pivotal in driving the hybrid automotive industry forward.

Beyond this, the technology also extends its reach to electronic components. Solenoids and reactors, for instance, benefit immensely from the precision and durability offered by glue-bonded assemblies.

Other Motor Laminations Assembly Process

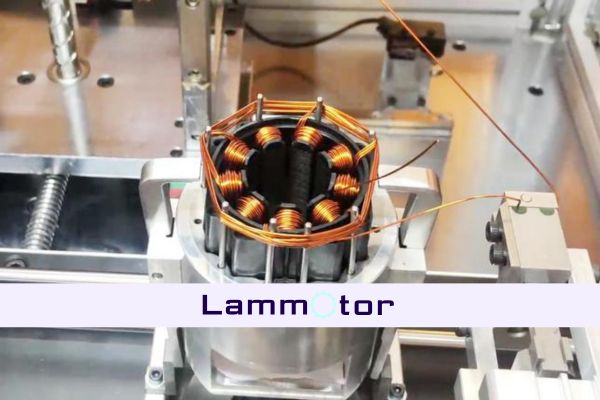

Stator Winding Process

Stator winding is a fundamental component of electric motors, playing a pivotal role in the conversion of electrical energy into mechanical energy. Essentially, it consists of coils that, when energized, produce a rotating magnetic field, driving the motor’s operation. The precision and quality of stator winding directly influence the motor’s efficiency, torque, and overall performance.

We provide comprehensive stator winding services, catering to a wide range of motor types and applications. Whether you’re looking for a solution for a small-scale project or a large industrial motor, our expertise guarantees optimal performance and longevity.

Epoxy Powder Coating for Electric Motor Core

The epoxy powder coating technique involves applying a dry powder, which is then cured under heat to form a solid, protective layer. It ensures that a motor core boasts increased resistance to corrosion, wear, and environmental factors. Beyond protection, epoxy powder coating also enhances the motor’s thermal efficiency, ensuring optimal heat dissipation during operations.

We’ve mastered this technique, offering top-tier epoxy powder coating services for motor cores. Our state-of-the-art equipment, combined with our team’s expertise, ensures a flawless application, enhancing both the lifespan and performance of your motor.

Injection Molding for motor lamination stacks

Injection molding insulation for motor stators is a specialized process used to create insulation layers that protect the windings of a motor stator.

This technique involves injecting a thermosetting resin or thermoplastic material into a mold cavity, which is then cured or cooled to form a solid insulation layer.

The injection molding process allows for precise and uniform insulation thickness, ensuring optimal electrical insulation properties. The insulation layer serves to prevent electrical shorts, reduce energy losses, and enhance the overall performance and reliability of the motor stator.

Electrophoretic Coating/Deposition for Motor lamination stacks

In motor applications exposed to harsh environments, stator core laminations are prone to rust. To combat this, an electrophoretic deposition coating is essential. This process applies a protective layer ranging from 0.01mm to 0.025mm in thickness to the laminations.

Leverage our expertise in stator corrosion protection to enhance your design with optimal rust-proof capabilities.

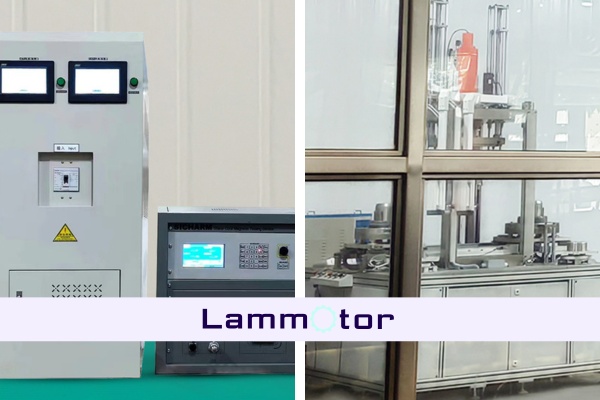

Quality control for Bonded lamination stacks

Quality control begins with the inspection of raw materials. The silicon steel sheets used for laminations must meet specific standards for purity, thickness, and electrical properties.

The adhesive selected for bonding should also be tested for consistency and performance characteristics.

Check the dimensions of the lamination stack to ensure they meet design specifications.

Plus, the bonded stacks undergo mechanical testing to assess the strength of the bond. This can include peel tests, shear tests, and tensile tests.

Failure analysis and aging resistance test for self-bonded motor cores: high and low-temperature oil resistance failure analysis, motor core iron loss detection, etc.

Benefits of Motor Bonding laminations

In the intricate world of motor assembly, the method chosen for bonding stator and rotor laminations can significantly influence the motor’s overall performance. Self-bonding, in particular, has emerged as a preferred choice for many manufacturers, and for good reasons.

Keeps the vibration at rotation low

One of the standout benefits of glue bonding is its ability to minimize vibrations during rotation. This not only ensures a smoother operation but also reduces wear and tear on the motor components, leading to a more stable performance.

Enhanced durability and longevity

Glue bonding enhances the motor’s cooling efficiency. With better heat dissipation, motors can operate for extended periods without overheating, thereby prolonging their lifespan.

Smooth stacking reduces wind noise

A motor that operates quietly is always desirable. Thanks to the smooth stacking achieved through glue bonding, wind noise is significantly reduced, making for a quieter motor operation.

Reduce iron loss and heat generation

Excessive heat can be detrimental to motor performance. Glue bonding ensures minimal iron loss, which in turn keeps heat generation in check, safeguarding the motor from potential damage.

Suitable for stacking thin/hard materials

Traditional bonding methods might struggle with thin or hard materials. However, glue bonding excels in this area, offering a reliable solution for stacking even the most challenging materials.

Improved motor efficiency

At the heart of it all, the primary goal is to achieve optimal motor efficiency. Glue bonding facilitates this by ensuring a tight bond between the stator and rotor, leading to enhanced motor performance and reduced energy consumption.

Bonded Lamination Stacks FAQs

We use imported glue that has passed 200 degrees high temperature and has UL certification to ensure the safety of its electrical performance.

These adhesive bonds are chosen for their strength, durability, and compatibility with the materials we work with, ensuring a robust bond that stands the test of time.

Absolutely. Our glue bonding technique is designed to endure high temperatures. The adhesives we use are heat-resistant, ensuring the bond remains intact even under extreme thermal conditions, making it ideal for high-performance motor applications.

While riveting and welding are traditional methods of assembly, glue bonding offers several advantages. It provides a smoother finish, reduces vibration, and allows for precision alignment.

Laser welding is an automated welding technique used to join stacked rotor and stator lamination stacks through the use of a fiber optic laser.

Additionally, glue bonding is often more suitable for thin or hard materials, ensuring a tighter and more efficient bond.

The curing duration can vary based on the adhesive type and the specific requirements of the project. Typically, our curing process ranges from a few hours to overnight, ensuring the adhesive achieves its maximum bonding strength.

A glue-bonded stator and rotor can have an extended lifespan, often outlasting traditional assembly methods. With proper care and under normal operating conditions, you can expect years of efficient and reliable performance.

The self-bonding process can be divided into primary coating, secondary coating, and in-mold dispensing.

A: Primary coating includes the following processes.

a) Coating of bare electrical steel sheets

b) Punch processing

c) Stacking and curing of the punches.

B: Secondary coating includes the following processes.

- Coating followed by punching.

a) Surface coating of electrical steel insulation.

b) Punching

c) Stacking and curing of punched sheets. - Punching and then coating: a) Punch processing

a) Punching

b) Surface coating of electrical steel insulation

c) Punching and curing in stacks.

C: In-mold dispensing consists of the following processes.

a) Punch progressive die stamping electrical steel insulation surface in-mold dispensing

b) In-mold curing of punches in the die at ambient or elevated temperatures.

Get Started with Our Self-Bonding Services!

Embarking on your next motor project? Let us elevate it with our expert rotor and stator bonding lamination stacks services. We’re more than just service providers; we’re your partners in achieving motor excellence.

Begin your journey with us through a straightforward consultation, where we’ll understand your requirements and guide you through our offerings.

Take the leap towards superior motor performance. Reach out today for a consultation or quote.