Lamination Stacks Fore permanent magnet Motor Manufacturer In China

We are a reliable lamination stacks for permanent magnet motor manufacturer in China. We have years of experience in this field, and our motor cores are well known for their high quality and performance. Our DC permanent magnet motor cores are used in various applications, including wind turbines, electric vehicles, industrial automation systems, and medical equipment.

design and manufacture stamping molds

As a China manufacturer of motor laminations, we are committed to providing our clients with top-notch stamping molds that meet their unique needs. We have the latest technology and tools to design and produce high-quality stamping molds that ensure optimal performance.

With years of experience in the industry, we have developed a deep understanding of the complex requirements of producing motor laminations. This has enabled us to develop extensive stamping mold designs tailored for various applications. Whether you need custom-made or standard stamping molds, we can provide reliable solutions that guarantee effective lamination production.

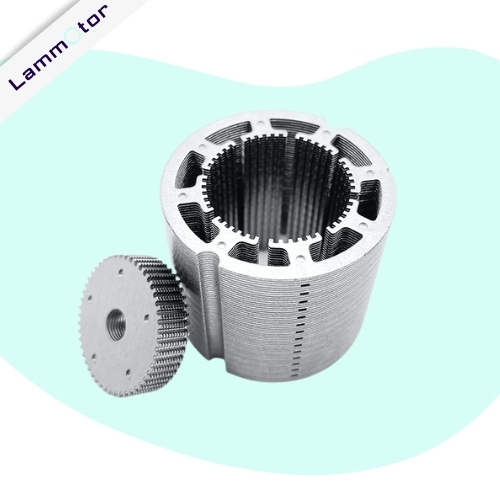

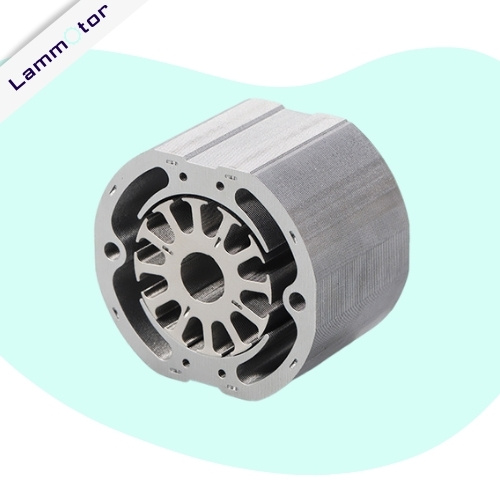

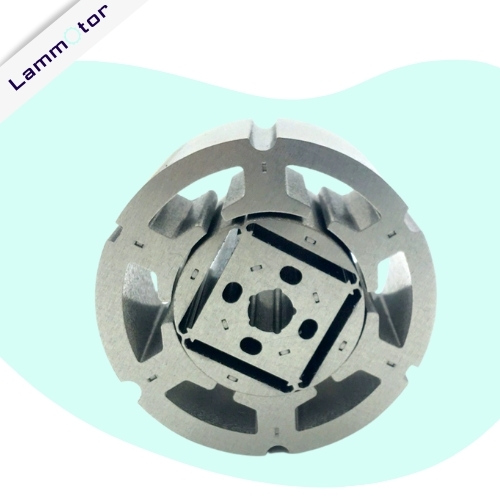

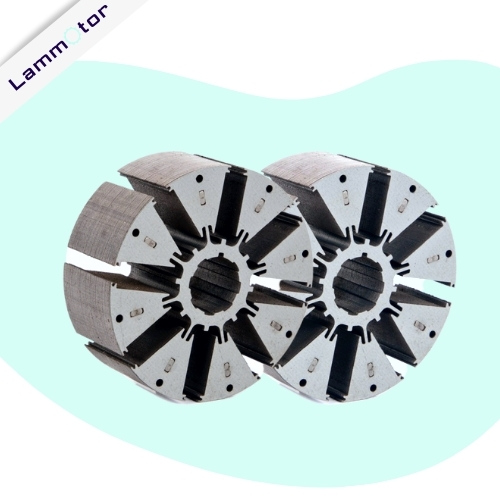

customized lamination stacks for permanent magnet motors

Permanent magnet motors are essential to many modern electronic devices, from industrial machinery to household appliances. At the heart of these motors lies a magnetic core that plays a critical role in converting electrical energy into mechanical energy.

We specialize in customizing different sizes and types of permanent magnet motor cores for various applications. We understand that every project has unique requirements regarding power output, durability, and cost-effectiveness. Therefore, we work closely with our clients to develop bespoke solutions that meet their needs.

OUR SERVICES

why choose us for permanent magnet Rotor Stator lamination stacks?

Design and Manufacturing

Our engineers can design the motor stator & rotor for permanent magnet motors according to customer requirements. They have mastered the production process, from raw material selection and production to quality control of finished products.

Cost-effective Solutions

We understand the needs of different industries and provide cost-effective solutions for motor stators & rotors for permanent magnet motors. We can provide competitive pricing plans.

Quality Control

We are committed to providing high-quality motor stators & rotors for permanent magnet motors. We employ stringent testing processes and inspect each product before it is delivered to customers.

lamination stacks for other motors

In addition to designing and manufacturing lamination stacks for permanent magnet motors, we can customize these stacks for other types of motors, including DC motors, stepper motors, and induction motors.

permanent magnet Motor lamination Stacks FAQs

What are the applications of permanent magnet motor cores?

Permanent magnet motor cores are suitable for a variety of applications. They include electric motors, generators, and actuators.

Permanent magnet motor cores can also be suitable for power transmission and vibration isolation. They are often suitable for robotics, automation systems, and industrial machinery, where their strong magnetic field helps to control the movement of the machine parts.

In addition, they can be suitable for energy storage since they can store electrical energy and convert it into mechanical energy as needed.

Furthermore, these cores are also suitable for pumps and fans due to their high torque output.

Finally, permanent magnet motor cores can generate electricity from wind or water.

All in all, permanent magnet motor cores have a wide range of applications, making them an essential component of any industry that relies on motion control or energy storage solutions.

Permanent Magnet Motor Core For Different Types of Permanent Magnet Motor

Brushless DC Motor (BLDC):

Brushless DC motors use permanent magnets to produce torque without brushes, making them an ideal choice for various applications, from medical devices and industrial machinery to automotive components. They are also more efficient than their brush-commutated counterparts, which makes them an appealing choice for energy-conscious applications.

Brushless AC Motor (BLAC):

Brushless AC motors are permanent magnet motors that utilize an alternating current to produce torque instead of relying on brushes, as many brush-commutated motors do.

Permanent Magnet Synchronous Motor (PMSM):

These motors utilize permanent magnets in the rotor and synchronous stator technology to deliver precise torque control while achieving high-efficiency levels. PMSM motors are used in various applications ranging from HVAC systems to hybrid vehicles.

Stepper Motor:

Stepper motors use permanent magnets and a rotating shaft to precisely control position or speed, making them an excellent choice for applications such as CNC machines and robotic arms. The number of poles in the motor can be customized for different levels of torque and resolution.

Linear Permanent Magnet Motors:

Linear permanent magnet motors use combinations of permanent magnets, electric coils, and bearings to create linear motion. They are used in various systems, such as conveyors, automated assembly lines, and medical imaging equipment. Their brushless design offers higher efficiency than traditional brushed DC motors.

Let’s get started on your motor lamination stack project!

Are you looking to get started on a motor laminations project? This can be daunting, but your project will be up and running quickly with the proper knowledge and guidance.