Lamination stacks for Industrial Electric Motor Manufacturer In China

We produce high-quality lamination stacks for industrial motor. Our custom-designed lamination stacks are carefully crafted to meet specific requirements and improve industrial motors’ efficiency, performance, and durability. Our team of experts has years of experience and knowledge in designing and producing lamination stacks for different types of motors, including pumps, air compressors, electric vehicles, and wind turbines.

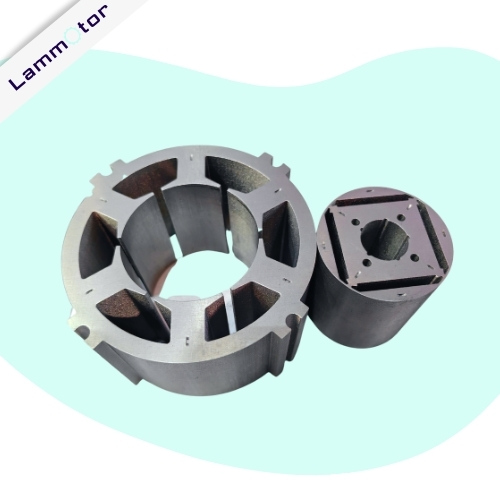

custom lamination stacks for industrial motor cores

Lamination stacks are critical components of industrial motors, providing a core for the motor windings and supporting the electromagnetic forces that drive the motor. In addition, lamination stacks are essential for controlling the flow of magnetic flux through the motor, which is crucial for the efficient operation of the motor.

Industrial motor cores device convert electrical energy into mechanical energy and enable the operation of various types of machinery, including pumps, fans, and compressors. We can customize industrial and new energy vehicles motor cores to give customers exactly what they need for their applications.

wind-driven generator motor core

OUR SERVICES

why choose us for industrial Motor Rotor Stator lamination stacks?

Design & Development

We can design and develop the motor rotor stator core for new energy vehicle motors according to customer requirements.

Production Capacity

We have production facilities equipped with the latest machinery to ensure high quality, accuracy, and productivity levels. Our production capabilities include stamping, laminating, welding, and assembly.

Quality Control

We have strict quality control procedures to ensure each motor core meets customer specifications and industry standards. Our raw materials are rigorously tested for quality before being used in production.

applications of lamination stacks for industrial motor

Lamination stacks are critical components in industrial motors, from large complex systems to compact devices. Here are some of the industrial motors’ most significant applications of lamination stacks.

Pumps and water treatment. Due to their low cost and versatility, they are used in various applications, from packaging plants to oil drilling.

Air compressors. They rely heavily on lamination stacks for high efficiency and long service life.

Electric vehicles. Electric vehicles like cars, trains, and planes require lamination stacks to control engine speed, improve efficiency, and reduce emissions.

Wind turbines. Finally, lamination stacks are utilized to produce wind turbines, which harness wind energy and convert it into electricity.

With the continuous development of lamination stacking technology, we can expect to see these machines used in more applications.

lamination stacks for industrial motor FAQs

Electric power tools are a staple in almost every handyman’s toolkit. These tools have revolutionized our work and made our lives significantly easier. The motor core is the central component that provides the necessary energy to run an electric power tool.

Furthermore, different types of motor cores are used in electric power tools, including brushed DC motors, brushless DC motors (BLDC), and universal motors.

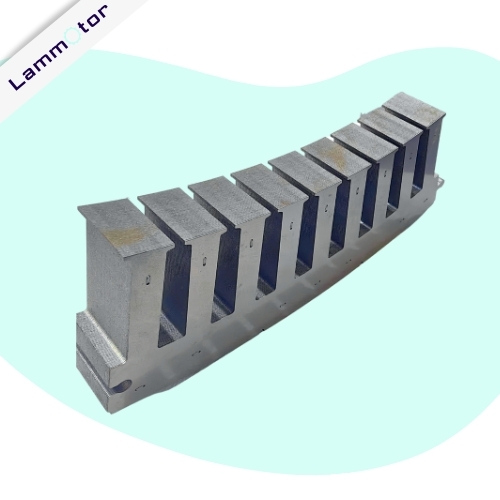

Wind-driven generator motor core is an essential component of wind turbines that generate electricity from the wind’s kinetic energy. The motor core is responsible for converting the mechanical energy obtained from the rotation of the turbine blades into electrical energy.

It comprises a group of laminated steel sheets stacked together and coated with an insulating material, which helps reduce heat generation and conserve power.

The size and shape of the motor core vary depending on the type and size of wind turbines.

However, most cores have a cylindrical shape with numerous slots that run axially along their length. These slots are crucial in holding copper wire coils that generate magnetic fields when electric current flows through them.

The magnetic field interacts with other components within the generator, like rotors, stators, or magnets, to create mechanical torque that drives the generator’s output shaft.

Elevator traction motor core lamination is an essential component of every elevator system. It is responsible for ensuring that the elevator moves smoothly and efficiently and providing power to the machinery.

A critical feature of elevator traction motor core lamination is its ability to reduce energy loss.

This is achieved through high-quality materials such as silicon steel laminations, known for their low electrical resistance and magnetic permeability.

As a result, minimum energy is wasted in heat dissipation or other forms of energy loss during operation.

Another key feature of elevator traction motor core lamination is its manufacturing precision.

The production process involves stacking individual laminations accurately and clamping them tightly to remain securely aligned even under heavy loads.

A. Enhancing Motor Efficiency

One of the primary functions of lamination stacks in industrial motors is to enhance motor efficiency by minimizing energy losses caused by eddy currents and hysteresis.

The laminations in the core of the motor are arranged in such a way as to reduce the magnetic resistance of the core, making it easier for the magnetic fields to create a rotational force.

The reduced magnetic resistance allows the motor to operate more efficiently, reducing energy consumption and improving overall performance.

B. Lowering Magnetic Losses

Lamination stacks can reduce the energy losses caused by eddy currents and hysteresis, leading to lower magnetic losses in the motor. These losses are created when the magnetic flux in the motor generates heat, which reduces efficiency and increases wear and tear.

C. Reducing Vibration and Noise

Lamination stacks can also help reduce vibration and noise in industrial motors. The laminations in the core of the motor provide a stable platform for the motor windings, reducing the vibration caused by the motor’s rotational forces. The reduced vibration improves the motor’s durability and can also reduce the noise produced by the motor during operation.

D. Increasing Motor Life Span

Lamination stacks increase the life span of the motor by reducing the wear and tear caused by energy losses and vibrations. The reduced wear and tear on the motor’s components can lead to longer lifespans for industrial motors, reducing maintenance and replacement costs.

Let’s get started on your motor lamination stacks project!

Please get in touch with us if you have any questions or concerns about our products or services. We will be happy to assist you!