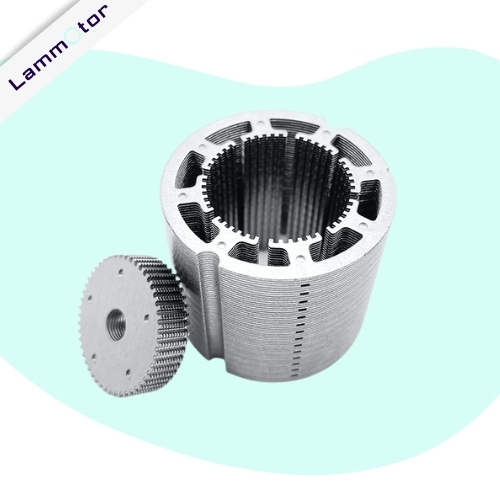

Lamination stacks for New Energy Vehicles Motor Cores In China

We are a reliable motor rotor stator lamination stacks manufacturer. We customize new energy vehicles motor core lamination stacks. And we have been providing our customers with the highest quality motor stator & rotor lamination stack for many years. We are committed to providing our clients with the best service possible.

customized lamination stacks for new energy vehicles motor

Electric motors are becoming increasingly important in the automotive industry as new energy vehicle technologies continue to develop. At Lammotor, we specialize in customizing motor stator rotor cores for various applications, including new energy vehicles and industrial applications. We ensure that each custom core is designed and tested to meet all requirements.

BLDC motor cores lamination stacks

BLDC is an electric motor with a permanent magnet rotor and electronically-controlled windings on the stator. It is one of the most efficient motors, offering high performance, compact size, and low maintenance cost.

induction electric motor lamination stacks

Induction electric motor cores are typically made from silicon steel or laminated sheets, with high electrical resistivity and low hysteresis losses.

Automobile micro motor core lamination

Automobile micromotor core laminations are responsible for powering the many motors that drive various parts of a car, including windshield wipers, electric windows, and even hybrid engines.

Permanent magnet synchronous motors

These cores are used in many industrial applications, such as pumps, fans, and conveyors. They can also be found in residential appliances such as washing machines, refrigerators, and vacuum cleaners.

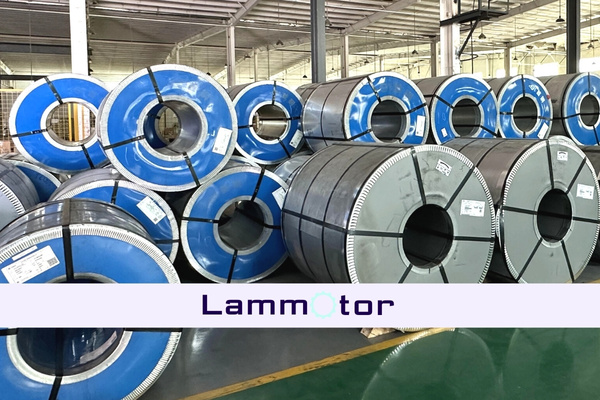

New energy drive motor core electrical steel materials

Permanent magnet synchronous motor is the mainstream trend of new energy vehicle development, with advantages such as high efficiency, high torque, high safety and small size.

Tesla, Lucid and other electric vehicles all use permanent magnet motors. In order to improve the efficiency of the drive motor, it is necessary to significantly reduce the loss characteristics of the electrical steel material itself, and the most direct way is to reduce the thickness.

Therefore, for the core of the drive motor of new energy vehicles, we often use 0.20, 0.25, 0.27, 0.30, 0.35mm Baosteel or Shougang electrical steel laminations.

Baosteel’s electrical steel laminations can be divided into the following series:

- Ordinary series: low iron loss and high strength; for example B20AV1200, B35AV1700, 30WGP1500

- High efficiency series: low iron loss and high magnetic induction; for example 20WTGH1300, 27WGPH1500

- High efficiency and high strength series: excellent comprehensive performance of magnetic induction, iron loss and strength; for example B27AHV1300M, B25AHV1300M

- High magnetic induction series: higher magnetic induction to meet the needs of high torque and motor miniaturization; for example B30APV1500, B35APV1700

- High strength series: high strength, used for high-speed or ultra-high-speed rotors. For example B35AHS500, B35AHS550

OUR SERVICES

why choose us for New Energy Vehicle Rotor Stator lamination stacks?

Design & Development

We can design and develop the motor rotor stator core for new energy vehicle motors according to customer requirements.

Production Capacity

We have production facilities equipped with the latest machinery to ensure high quality, accuracy, and productivity levels. Our production capabilities include stamping, laminating, welding, and assembly.

Quality Control

We have strict quality control procedures to ensure each motor core meets customer specifications and industry standards. Our raw materials are rigorously tested for quality before being used in production.

lamination stacks for new energy vehicles motors FAQs

Manufacturing of Lamination Stacks for Motor Core

The manufacturing process for lamination stacks for motor cores can be broken down into several stages:

Raw Material Selection: Choosing the right raw material to conform to specific standards of thickness, magnetic properties, and metallurgical quality.

Stamping and Cutting: The material is stamped and cut according to the desired shape, precisely done to ensure uniformity.

Annealing and Tempering: The stacks are heated, annealed, and tempered to reduce the risk of cracking and warping while giving them the necessary magnetic properties.

Coating and Insulating: The stacks are coated with an insulating material to prevent conducting electricity, protect them from wear, and enhance performance.

The Role of Lamination Stacks in the New Energy Vehicle Motors

Lamination stacks play a crucial role in enhancing the performance of new energy vehicle motors. The following are some of the key roles played by lamination stacks in new energy vehicle motors:

A. Increase Efficiency: Lamination stacks reduce energy loss due to eddy currents by creating a path of least resistance for the magnetic flux. This leads to higher motor efficiency and reduces the energy required to operate the motor.

B. Reduce Energy Consumption: Improved efficiency due to lamination stacks means less energy is required to power the motor, reducing the overall energy consumption and increasing the range of the new energy vehicle.

C. Enhance Reliability: Lamination stacks are made from materials resistant to corrosion and wear, increasing their reliability and lifespan. This ensures the motor can operate optimally under demanding conditions without deteriorating quickly.

D. Improve Performance: Lamination stacks reduce magnetic pitting, eddy currents, and iron losses, leading to improved performance, higher torque, and increased power output.

E. Decrease Noise and Vibration: Lamination stacks can help reduce noise and vibration levels by minimizing the effects of magnetic forces on the motor’s rotor and stator. This results in a smoother and quieter operation, leading to a more comfortable driving experience for the occupants.

Let’s get started on your Lamination stacks project!

Please get in touch with us if you have any questions or concerns about our products or services. We will be happy to assist you!