Home Appliance Motor Laminations Stacks In China

As a motor lamination stacks China manufacturer, we specialize in manufacturing all kinds of electric motor lamination cores. We make different home appliance motor laminations, including air conditioner compressors, washing machines, and fans.

Our technical team is experienced and has many years of experience in manufacturing. We own advanced technology in prototyping, stamping, stator winding, and bonding lamination stacks.

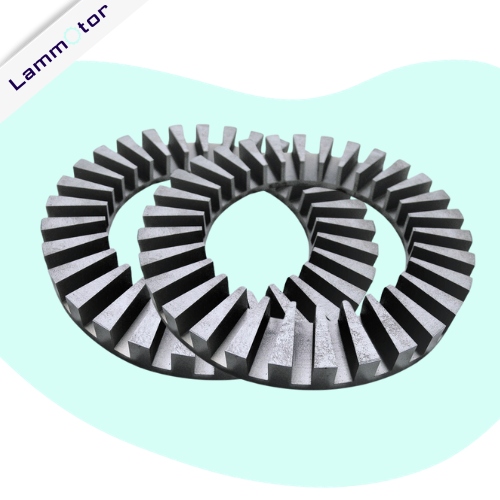

Customized Stator and Rotor Lamination Stacks for Household Appliance Motors

The various types of motor stators and rotors we produce are widely used in automobile motors, power tool motors, household appliance motors, etc. We can customize a range of silicon steel lamination stacks tailored specifically for household appliance motors.

It spans various appliances including washing machines, refrigerators, air conditioners, fans, and more. Each electrical steel lamination stack is meticulously engineered to address the distinct requirements of different motor applications.

Washing machine BLDC motor stator rotor stacks

Refrigerator motor stator rotor lamination stacks

Home Appliance Motor Laminations Stamping Die

We can design and manufacture motor stator and rotor stamping dies for home appliance motors. These precision tools are crucial for producing accurate and consistent laminations, ensuring the efficient operation of your motors.

We have mold production and maintenance departments, and professional maintenance engineers will regularly check the use of molds, for timely maintenance. The die life time normally is 150-200 million strokes.

Assembly Of Motor Lamination Stacks for Home Appliances

We also offer the following services:

Welding: Weld together individual laminations to form a cohesive stack, ensuring structural integrity and alignment for optimal motor performance. Also, we provide the interlock method.

Bonding: Utilizing advanced bonding techniques, we securely adhere laminations together, enhancing stability. We provide glue bonding and self-bonding.

Epoxy Coating: To safeguard against corrosion and improve insulation properties, we apply a durable epoxy coating, such as 3M266, to the assembled lamination stack.

Winding: Wind copper coils onto the stator lamination stack, following precise specifications to optimize electrical conductivity and efficiency, resulting in smooth and reliable motor operation.

Other Products

Looking for a Home Appliance Motor Laminations Manufacturer in China?

If you’re seeking a reliable and experienced manufacturer for home appliance motor core laminations in China, Contact Lammotor. With our dedication to quality, customization, and customer satisfaction, we are your trusted partner in delivering superior motor lamination solutions. Contact us now to discuss your requirements, explore our comprehensive range of stator and rotor products, and experience the difference with Lammotor.