custom lamination stacks for servo Motor Manufacturer In China

Lamination stacks for servo motor are crucial components that help ensure servo motors’ optimal performance and efficiency. These stacks are essentially made of thin layers of magnetic and non-magnetic materials that are stacked together to form a core, which is then used in the production of servo motors.

We are a reliable rotor and stator lamination stacks for servo motor manufacturer. Our custom motor stator and rotor laminations are of the highest quality, and we offer competitive prices that can’t be beaten. Contact us today if you need help choosing the best option for your specific project!

stamping capability

Our stamping capabilities for servo motor core lamination are second to none.

We utilize a state-of-the-art stamping process, such as compound stamping and progressive stamping, that achieves superior accuracy. Our equipment is regularly calibrated and inspected to ensure the highest production quality.

Our company specializes in customizing servo motor cores to suit any application. Different motors require different lamination designs and materials to ensure maximum efficiency and reliability. We can produce customized laminations based on specific requirements and specifications.

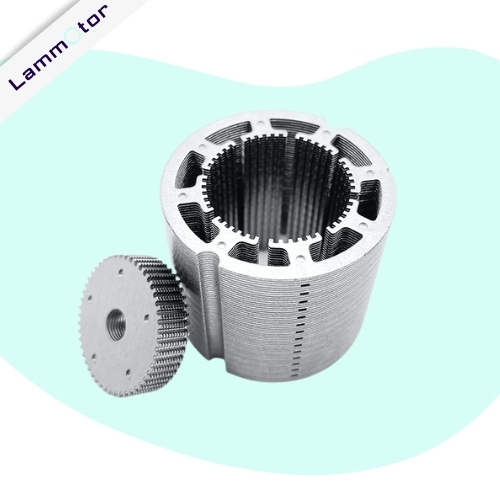

customized lamination stacks for servo motor cores

We can customize various diameters of motor stator & rotor lamination stacks for customers. Whether you’re looking for a small stator or a large one, we have the capacity and capability to meet your needs. Our custom stator rotor diameter range is 15-180mm. We also customize DC motor cores, induction motor cores, and stepper motor cores.

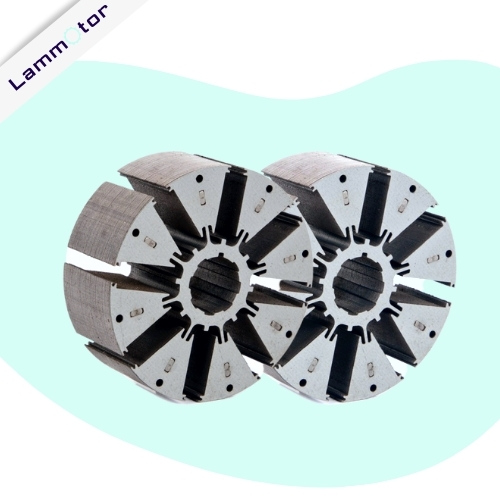

Universal servo motor rotor

Universal servo motor rotors are a type of motor rotor that can be used on both AC and DC motors.

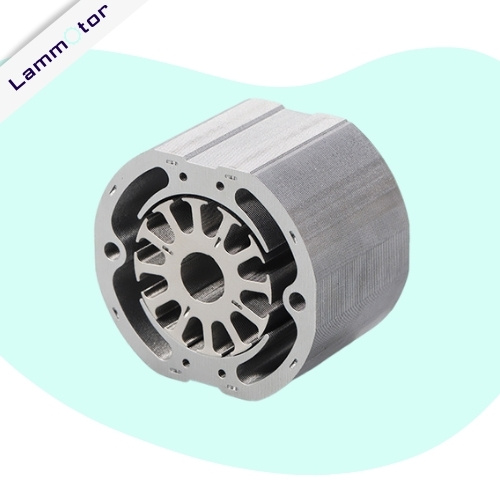

AC Servos Motor core

The AC servo motor core comprises several parts, including a stator, rotor, and electrical components such as windings and magnets.

DC Servos Motor rotor stator

DC servo motors are suitable for robotics and automation control systems because they are reliable and efficient at producing high-torque output under varying speed loads.

OUR SERVICES

why choose us for servo Motor Rotor Stator lamination stacks?

quality assurance

The quality control team tests the materials for dimensional accuracy, electrical properties, surface finish, noise level, and other requirements as per industry standards.

Production Capacity

We have production facilities equipped with the latest machinery to ensure high quality, accuracy, and productivity levels. Our production capabilities include stamping, laminating, welding, and assembly.

flexibility

Our manufacturing unit can develop customized solutions per our customer’s requirements. We have a team of experienced engineers who can assist our customers in developing new products or modifying existing designs.

lamination stacks for other motors

In addition to designing and manufacturing lamination stacks for servo motor, we can customize these stacks for other types of motors, including DC motors, stepper motors, and induction motors.

Each of these motors operates differently and has unique performance requirements. For instance, DC motors require laminations with lower core losses and higher magnetic permeability to achieve optimal performance. Stepper motors rely on precise alignment of the laminations for accurate movement control. To ensure high efficiency, induction motors need laminations with high magnetic permeability and low eddy current losses.

We have extensive experience designing and manufacturing lamination stacks for these motors, and we ensure that the laminations meet the performance requirements of each motor type.

servo Motor lamination stacks FAQs

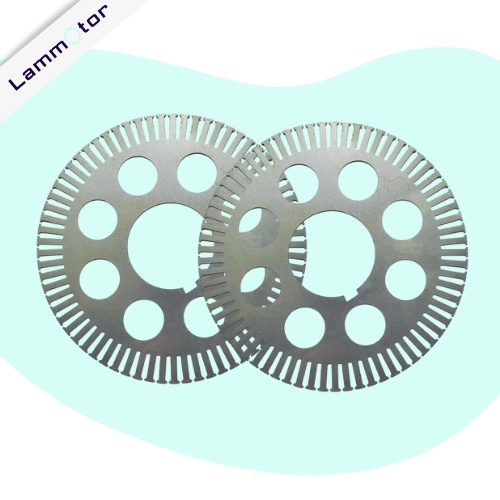

methods of stacking for motor lamination stacks

Stacking motor laminations is a critical process in the manufacture of electric motors. There are different methods of assembling the laminations, the most common being welding, gluing, and riveting.

Welding involves fusing the laminations using heat and pressure to form a unified stack.

Gluing entails using adhesives to hold the laminations together.

Riveting involves securing the laminations with fasteners, such as bolts or rivets.

What’s the material used in servo motor lamination stacks?

One servo motor core lamination material type is silicon steel, electrical steel, or transformer steel.

It has high electrical resistance and low magnetic hysteresis loss, making it ideal for motors due to its ability to generate strong magnetic fields with minimal energy input.

What are the benefits of servo motor cores?

Servo motor core rotor and stator laminations offer many benefits.

They are highly efficient, with low electrical losses and a high power density, allowing smaller motors to generate more torque.

They also have excellent heat dissipation properties, which help to protect the motor from damage due to overheating.

Additionally, they are very durable and have a long service life. Servo motors with core rotor and stator laminations also provide precise control of position, speed, and torque, making them ideal for applications that require accuracy.

Finally, they are relatively inexpensive compared to other motors, making them an economical option for many applications.

Applications of Lamination Stacks for Servo Motor

A. Robotics

Servo motor lamination stacks are essential in robotics applications. They provide the necessary torque required, allow the device to operate at extreme temperatures, and maintain the highest level of precision.

B. Motion Control Systems

Motion control systems depend on the accuracy and precision of the device with input from sophisticated software. Lamination stacks are ideal for such applications.

C. Industrial Automation

Lamination stacks for servo motors are employed in large-scale automation systems, including assembly lines across different industries, including food processing, textiles, and automotive industries.