Linear Motor Laminations Manufacturer in China

As a leading China manufacturer of motor lamination stacks, we specialize in delivering top-notch linear motor laminations tailored for various electric motors.

Our linear laminations are suitable for electronic and semiconductor equipment, the photovoltaic lithium battery industry, the UV inkjet industry, precision CNC machine tools, high-end medical devices, and other fields.

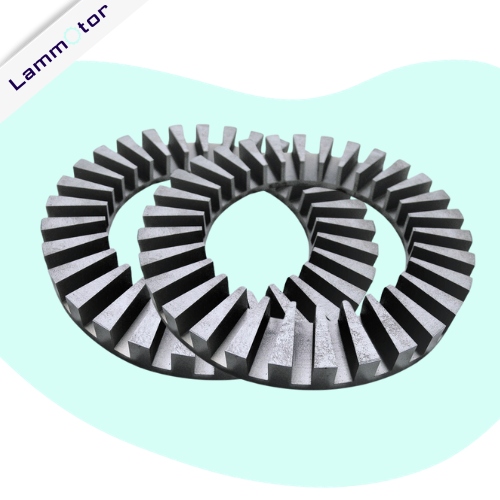

Customize Laminations Stacks For Linear Motor

Linear motor laminations are essential components in the construction of linear motors, serving as the core material for the motor’s stator. These laminations are typically made of high-grade electrical steel sheets, designed with precision-cut slots to accommodate winding coils.

High-quality laminations reduce energy losses, enhance magnetic flux, and improve overall motor efficiency. Linear motors find applications in various industries, such as manufacturing, transportation, and robotics, where precise and rapid linear motion is crucial.

We specialize in tailoring high-quality linear laminations to meet the unique specifications of linear motors.

Our expertise lies in customizing these laminations to precise dimensions, ensuring an optimal fit for specific linear motor designs. By utilizing high-quality materials and stamping and wire EDM techniques, we enhance the overall performance and efficiency of linear motors.

Stamping Die of Linear Motor Laminations

The stamping die serves as a crucial tool for mass-producing linear motor stator laminations. As a leading stamping die manufacturer based in China, we specialize in crafting precision molds.

Our stamping dies contribute to the reliable and efficient production of linear motor components.

In addition, we provide a series of precision motor core stamping dies, such as stepper motor core molds, new energy motor core molds, segmented motor core progressive dies, etc.

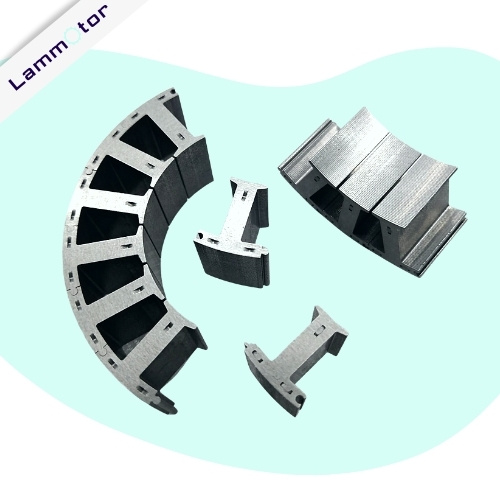

Injection Molding for Linear lamination stacks

Injection molding for insulating linear motor lamination stacks involves a precise process to ensure the production of high-quality components. First, a suitable insulating material, such as thermoplastic or thermosetting polymers, is selected based on its electrical and mechanical properties.

The material is then heated to a molten state and injected into a mold cavity that is specially designed to form the desired shape of the lamination stack. The mold is typically made from hardened steel to withstand the high pressures and temperatures of the injection molding process.

Once injected, the material is allowed to cool and solidify, forming the insulating layer around the motor laminations. This process ensures uniform insulation and tight tolerances for optimal performance of the linear motor.

OUR SERVICES

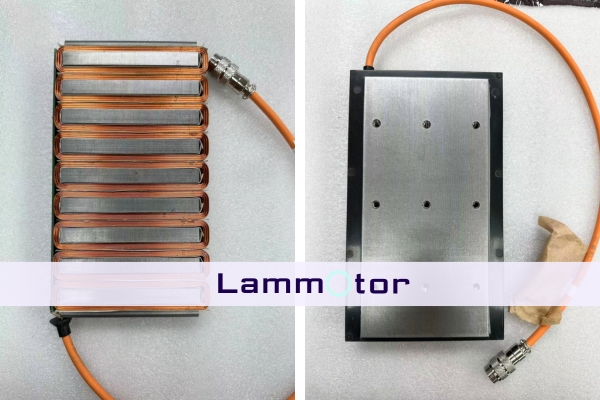

linear motor laminations Winding

The winding process for linear motor lamination stacks involves carefully wrapping insulated copper wire around the laminations to create the electromagnetic coils.

Each coil is wound in a specific pattern and number of turns to achieve the desired performance characteristics, such as torque and speed. The wire is typically wound around a bobbin or form to maintain the shape and spacing of the coils.

Additionally, the winding process may include techniques such as layering or interleaving to optimize the magnetic field distribution and reduce eddy currents. After winding, the coils are often impregnated with varnish or epoxy for insulation and mechanical stability.

Features of Linear Motor Laminations

- Simple Structure: Streamlined design for ease of integration.

- High-Speed Linear Motion: Suitable for applications demanding rapid and precise linear movements.

- High Primary Winding Utilization: Maximizes efficiency in electrical energy utilization.

- No Lateral Edge Effect: Eliminates unwanted lateral magnetic effects for enhanced precision.

- Unilateral Magnetic Tension: Easily overcomes unilateral magnetic forces, ensuring smooth operation.

- Easy Adjustment and Control: Offers flexibility in customization and control.

- Strong Adaptability: Adapts seamlessly to diverse operational environments.

- High Acceleration: Enables swift acceleration for dynamic applications.

- Accuracy: Precision in design and manufacturing for accurate motor performance.

- Speed: Capable of delivering high-speed linear motion without compromising accuracy.

OUR PRODUCTS

Applications of linear motors

Linear motors find applications across various industries due to their precise and efficient linear motion capabilities.

- CNC machine: Linear motors are used for high-precision positioning and rapid movement in CNC machining applications.

- Electronic semiconductors: Linear motors are employed in semiconductor manufacturing equipment for wafer handling and lithography processes.

- PCB board assembly: Linear motors assist in the precise placement of components during printed circuit board (PCB) assembly processes.

- Robotics: Linear motors power the linear motion of robotic arms and manipulators in industrial and collaborative robot applications.

- High-speed transportation: Linear motors are utilized in magnetic levitation (maglev) trains and high-speed transportation systems for efficient and smooth propulsion.

- Medical instruments: Linear motors enable precise movement in medical imaging devices, robotic surgery systems, and laboratory automation equipment.

Other Products

FAQs

Our customizations involve precision cutting of high-quality electrical steel to meet specific dimensional requirements. Tailored to exact specifications, the process ensures optimal fit and performance, enhancing efficiency and functionality in diverse applications.

Our quality control involves rigorous checks at every stage of production. From material selection to precision cutting and final inspection, stringent measures ensure that the linear motor laminations meet high-quality standards, guaranteeing optimal performance and reliability.

Linear Laminations are predominantly crafted from high-grade electrical steel sheets. These materials possess excellent magnetic properties, crucial for efficient energy transfer and overall linear motor performance.

Certainly! Our linear motor cores find applications in various industries, such as manufacturing, transportation, and robotics. They contribute to precise and rapid linear motion, showcasing versatility and efficiency in real-world scenarios.

Looking For A Linear Motor Laminations China Manufacturer?

Are you in search of a reliable and experienced linear lamination manufacturer in China? Look no further! At Lammotor, we specialize in crafting customized solutions tailored to meet your specific needs. Our cutting-edge manufacturing facility, commitment to quality, and extensive industry expertise make us the ideal partner for your linear motor cores requirements.

Elevate your electric motors with precision-engineered components that guarantee efficiency and durability. Contact us today to discuss your project, explore customization options, and experience the unmatched quality of our linear laminations.