Air Conditioner Motor Laminations in China

We are an air conditioner motor laminations China manufacturer, producing high-performance AC motor cores, BLDC motor cores, and compressor motor cores for residential, commercial, and industrial air conditioner motors.

We can provide various grades of silicon steel laminations, such as B35A250, B50A350 and more. Contact us for reliable, energy-efficient motor laminations that enhance the longevity and performance of your air conditioning systems.

Customize Air Conditioner Motor Core Laminations

A typical air conditioner includes three key motors: the compressor motor, the blower motor, and the fan motor. We specialize in manufacturing the motor cores for all of these components, producing air conditioner AC motor cores, air conditioner BLDC motor cores, air conditioner compressor motor cores, and fan motor cores.

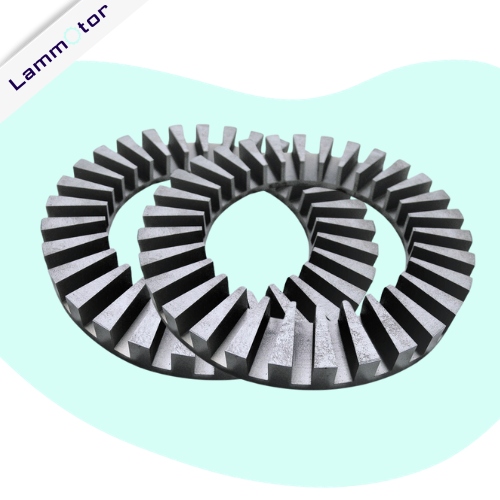

Air conditioner compressor motor core

AC air conditioner motor lamination stacks

air conditioning fan motor stator

air conditioning fan motor rotor

Manufacturing Capabilities for Air Conditioner Motor Laminations

Mold Design and Manufacturing

We can manufacture various die types, including interlocked progressive molds, auto riveting progressive molds, and compound dies.

We offer flexible options with single or multi-cavity designs to meet specific production requirements. You can choose loose sheet or auto-interlocked stacking.

For the mold materials, normally we use YG15, YG20, DC53, SKH-9, SKH51, SKD11, and D2, we ensure the durability and precision of each mold.

Compound Stamping and Progressive Stamping

We employ both compound stamping and progressive stamping techniques to produce motor laminations efficiently and accurately.

Compound stamping can create intricate parts in one operation, while progressive stamping enables high-speed production of complex lamination stacks, reducing waste and ensuring tight tolerances.

Rotor Die Casting

During the die-casting process, highly conductive materials (such as aluminum or copper) are injected directly into the slots of the rotor core to form guide bars and end rings, which reduces the rotor resistance and thus improves the efficiency of the motor.

Air Conditioning Motor Stator Winding

We have a complete stator winding production line for air conditioner compressor motors and can make windings according to your drawings. The main function of stator winding is to generate a magnetic field.

When current passes through the winding, a rotating magnetic field is formed in the stator, thereby driving the rotor to rotate and realizing the work of the motor.

Other Products

FAQs

We use high-quality silicon steel grades to ensure optimal performance for air conditioner motor laminations. Some of the key grades we work with include B35A300, B50A470, M530-65A, B50A600, B50A800, and M270-50A.

These materials are selected for their excellent magnetic properties, low core losses, and high efficiency. Depending on your specific motor requirements, we can customize the material to ensure the best performance and energy efficiency for your air conditioning systems.

An air conditioner compressor plays a crucial role in the cooling process by compressing the refrigerant gas, increasing its pressure and temperature.

The high-pressure gas then moves to the condenser, where it releases heat and turns into a liquid.

This liquid refrigerant circulates through the evaporator coil, absorbing heat from indoor air.

The cycle repeats, enabling continuous cooling. The compressor is the heart of this process, driving the flow of refrigerant throughout the system.

Air conditioners typically use three types of motors: compressor motors, blower motors, and fan motors. Compressor motors can be either AC motors or BLDC motors, depending on the system.

Blower and fan motors are designed to circulate air and maintain airflow efficiency, with BLDC motors offering greater energy efficiency and quieter operation.

Contact Us for Air Conditioner Motor Core Solutions

Looking for high-quality air conditioner motor stator and rotor cores in China? Contact us today for customized solutions that meet your specific motor design needs. Whether you need AC motor cores, BLDC motor cores, or compressor motor cores, our expert team is ready to assist. Reach out now for a consultation or to request a quote!