Injection Molding Insulation For Motor Stator Stacks

In the field of electric motors, the insulation of motor stator stacks plays a critical role in ensuring the efficient and reliable performance of the motor. Over the years, we have developed various techniques to enhance insulation properties, and one such technique is injection molding plastic insulation.

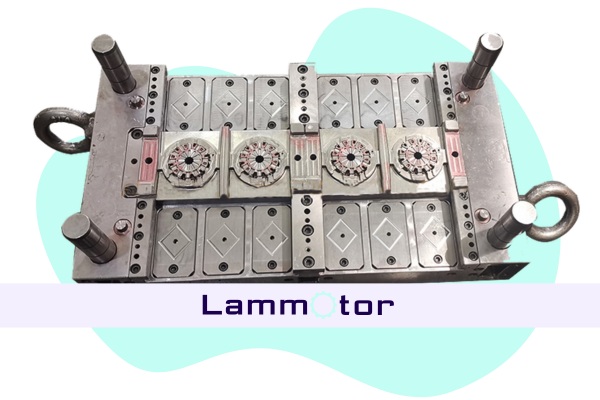

Injection Mold Design and Fabrication

At Lammotor, we offer comprehensive injection mold design and fabrication services. Based on the assessment, we design and fabricate a custom mold that perfectly accommodates your motor stator stacks.

The mold is crafted with precision to ensure an exact fit and optimal injection molding results. With our expertise and state-of-the-art facilities, we ensure precise and efficient mold design and fabrication.

Materials Used for Injection Molding

We provide various plastic materials for injection molding motor stator stacks. It depends on the specific application requirements. Common materials include thermoplastic elastomers (TPE), thermosetting plastics, and epoxy resins.

The selection of the material depends on factors such as temperature resistance, mechanical properties, and compatibility with the motor’s operating environment.

What Is Injection Molding Plastic Insulation

Injection molding for motor stators is a specialized process used to create insulation layers that protect the windings of a motor stator.

This technique involves injecting a thermosetting resin or thermoplastic material into a mold cavity, which is then cured or cooled to form a solid insulation layer.

The injection molding process allows for precise and uniform insulation thickness, ensuring optimal electrical insulation properties. The insulation layer serves to prevent electrical shorts, reduce energy losses, and enhance the overall performance and reliability of the motor stator.

Additionally, injection molding offers the advantage of producing complex shapes and intricate designs, accommodating various motor sizes and configurations.

With its efficiency and versatility, injection molding plays a crucial role in the manufacturing of high-quality motor stators.

Injection molding Plastic Insulation Process

Plastic injection molding for motor stator lamination stacks is a specialized process designed to enhance the electrical insulation and mechanical integrity of the stator in electric motors. This process involves the encapsulation of stator lamination stacks using thermosetting plastic materials, typically epoxy resins or other polymer compounds.

First, the stator lamination stacks are precisely positioned within a specialized mold. Then, thermosetting plastic material, often epoxy resin, is injected into the mold under high pressure. This ensures complete encapsulation of the lamination stacks.

The high temperature and pressure conditions facilitate the curing of the plastic, forming a robust insulation layer. This process not only provides electrical insulation but also enhances the mechanical strength of the stator.

After curing, the mold is opened, and the insulated stator is removed, ready for further assembly or testing.

Our Commitment to Customer Satisfaction

We prioritize customer satisfaction and strive to exceed expectations in every aspect of our services. When you choose us for your injection molding plastic insulation needs, you can expect:

- Personalized solutions tailored to your specific requirements

- In-house tool design and manufacturing

- 100% insulation quality testing

- Linked stamping and injection molding technologies

- Exceptional quality materials and craftsmanship

- Timely completion of projects

- Transparent communication and regular updates

- Dedicated customer support throughout the process

- Competitive pricing and cost-effective solutions

Applications of Injection molding Plastic Insulation

Injection molding plastic insulation finds applications in a wide range of industries where electric motors are utilized. Some notable applications include:

Automotive Industry: Overmolded stator stacks are commonly used in electric vehicles, hybrid vehicles, and various automotive systems.

Industrial Automation: Motors used in industrial automation equipment often benefit from the improved insulation and durability provided by over-molding.

Appliances: Overmolding enhances the performance and longevity of motors used in household appliances such as refrigerators, washing machines, and air conditioners.

Motor Stator Injection Molding FAQs

Insulation is crucial because it prevents electrical shorts and ensures the proper functioning of the motor stator. It helps to minimize energy losses, improve efficiency, and enhance the overall performance and longevity of the motor.

Injection molding offers precise control over insulation thickness, resulting in uniform electrical properties. It allows for complex shapes and intricate designs, accommodating different motor sizes and configurations. The process also ensures efficient production, high repeatability, and excellent insulation performance.

By providing reliable electrical insulation, overmolding insulation reduces the risk of electrical breakdowns, improves insulation resistance, and minimizes energy losses. This leads to enhanced motor efficiency, increased reliability, and extended operational lifespan.

For more information and access to over-molding plastic insulation services, contact us now.

Contact Us for motor stator injection molding!

We specialize in providing top-quality overmolding plastic insulation services for motor stator stacks. Our expertise in this field enables us to enhance the insulation properties of motor stators, ensuring optimal performance and reliability. With our advanced techniques and high-quality materials, we deliver solutions that meet the specific needs of our clients. Contact us for injection molding insulation for stators.