Motor Lamination Materials

Motor lamination materials play a crucial role in the design and performance of electric motors. We offer a variety of high-quality motor lamination materials to meet the needs of different motor applications. We provide efficient and reliable solutions, Whether for generators, electric motors, transformers, or electric vehicle motors.

Electrical Steel Materials Grades We Provide

We offer various high-quality Grian-oriented electrical steel and No Grian-oriented electrical steel materials to ensure the performance requirements of different motors and transformers are met. Below are some of the major brands and grades we offer:

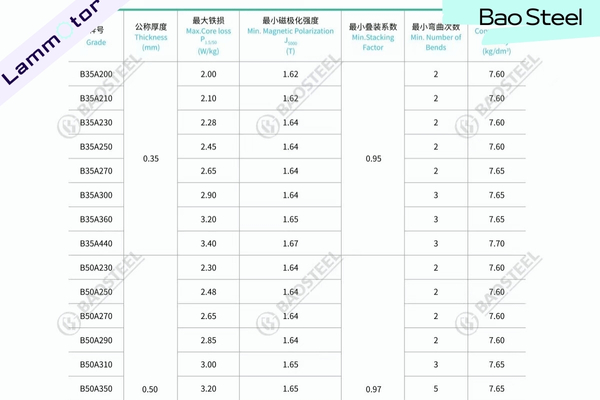

Baosteel

- B15AT1000, B20AT1200, B20AT1500, B20AV1200, B20AV1300, B25AV1300, B27AV1400, B30AV1500

- B35AV1700, B35AV1800, B35AV1900, B35AV2000, B35AV2100

- B35A250-Z, B35A270-Z

- B50A250, B50A270, B50A290, B50A310

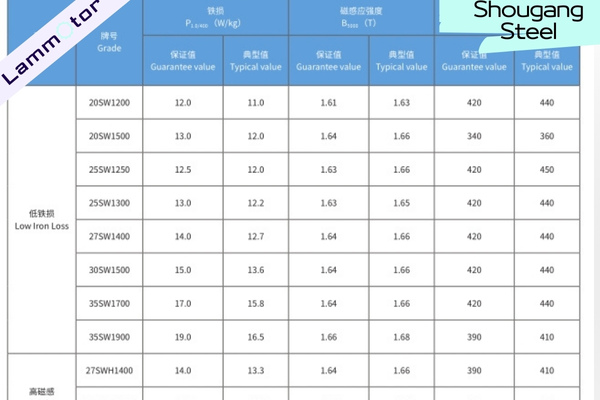

Shougang Steel

- 20SW1200, 20SW1500, 25SW1300, 27SW1400, 30SW1500, 35SW1700, 35SW1900

- 27SWH1400, 30SWH1500, 35SWH1900

- 27SWG1400, 30SWG1500, 35SWG1700

- 35SWYS500, 35SWYS900

- 25SW1250H, 27SW1400H, 30SW1500H, 35SW1700H

Kawasaki Japan: 15JNEH1000, 20JNEH1200, 20JNEH1500, 20JNHF1300

Ultra-Thin Silicon Steel: ST100

Other Materials We Provide

In addition to traditional electrical steel, we also offer other special materials to meet the needs of high-end applications:

Amorphous Alloy

Amorphous alloys have extremely low hysteresis loss and high magnetic saturation, making them suitable for high-performance motors such as high-frequency transformers and small efficient motors.

Soft Magnetic Composite

Soft magnetic composites perform excellently in high-frequency motor applications, effectively reducing losses and improving magnetic permeability. We can provide materials such as Somaloy 1P, Somaloy 3P, and Somaloy 5P.

Iron-Cobalt Alloy

Iron-cobalt alloys have high magnetic permeability and high saturation magnetic flux, suitable for high-energy applications such as high-performance motors and electric tools. We offer materials like China’s 1J21, 1J22, 1J27, which are equivalent to Hiperco 50 and Hiperco 27.

Different Motor Applications of Lamination Materials

Different types of motors require different lamination materials. Below are some common applications and the recommended materials:

- Transformers typically use grain-oriented silicon steel, which has low magnetic loss and high saturation magnetic flux, making it ideal for high-power transformers.

- Electric vehicle motor laminations often use non-oriented silicon steel or amorphous alloys, as these materials provide higher efficiency and lower energy consumption, making them ideal for high-efficiency drive systems.

- Ultra-thin silicon steel is widely used in precision motors, such as micro-motors and high-frequency transformers, helping reduce energy loss and improving motor performance.

Our Motor Laminations Manufacturing Capabilities

We offer prototyping and large-scale motor lamination manufacturing. Our custom manufacturing and assembly solutions can meet all your motor lamination needs – from reverse engineering to final production.

Our motor lamination services include:

Contact Lammotor for Motor Laminations

If you have any questions about motor lamination materials or our manufacturing capabilities, feel free to contact us. Our professional team will provide customized solutions according to your needs.