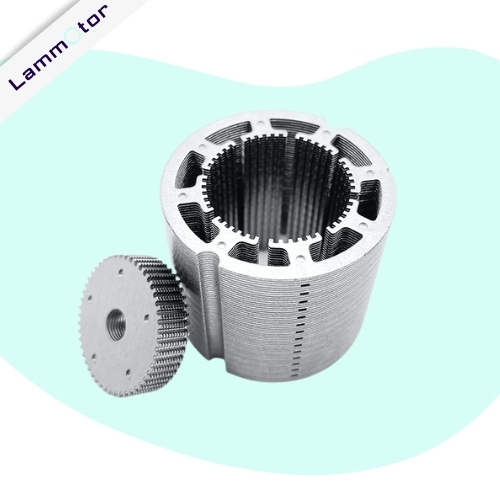

Segmented Stator Laminations Stacks in China

As a segmented stator laminations stacks manufacturer in China, we specialize in the production of stator lamination stacks, we offer precisely crafted segmented stator stacks tailored to diverse electric motor needs.

Our core strength lies in customization, ensuring your specific requirements are met with precision. In addition to stamping segmented stator stacks, we excel in welding and bonding services, complemented by expertise in stator winding. Trust us for quality solutions that enhance motor performance.

Customize segmented Stator lamination stacks for motors

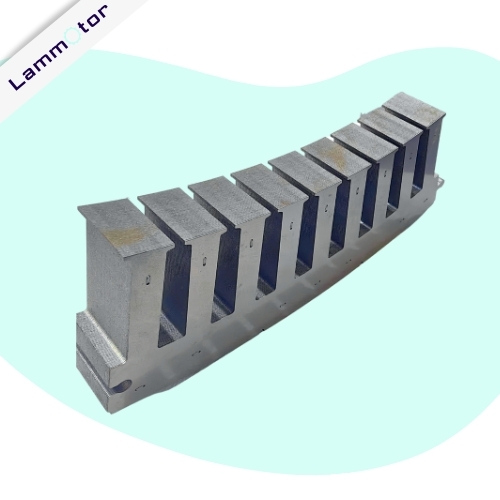

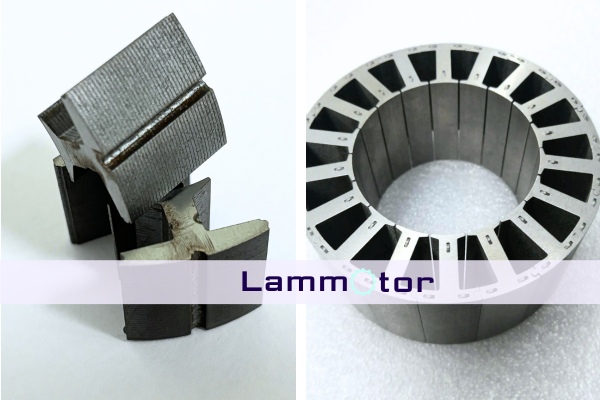

Segmented lamination stacks are essential components in the manufacturing of large motors, which are used in various industrial applications. These laminations consist of a series of segmented silicon steel plates that are designed to fit together to form the core of the motor.

We specialize in producing high-quality segmented lamination stacks for large motors, new energy vehicle motors, wind energy, brushless motor stators, elevator traction motors, and linear laminations.

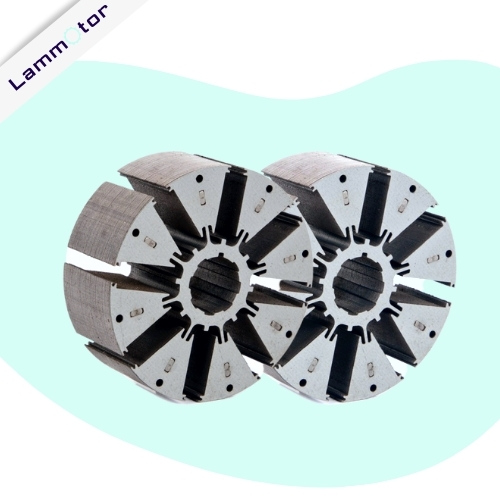

Segmented Motor Laminations Stacking

Segmented laminations stacking is a crucial process in the assembly of transformers and motors, reducing energy losses.

Welding involves fusing these laminations seamlessly, ensuring structural integrity and optimal magnetic performance.

Additionally, the dovetail slot method utilizes interlocking slots, enhancing stability and facilitating easy assembly. This innovative approach not only ensures a robust stack but also simplifies maintenance and repairs, making it a preferred choice for applications demanding precision and efficiency in the utilization of segmented laminations.

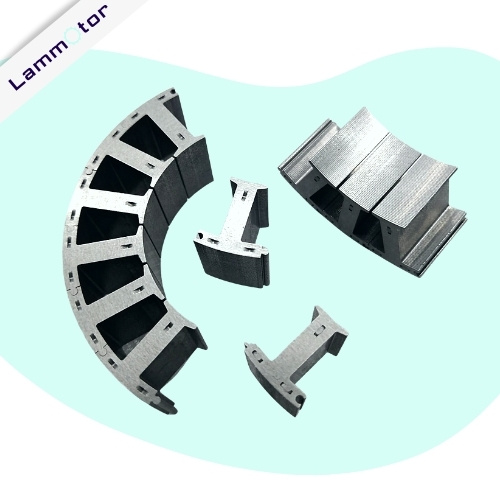

Plastic Injection Molding for Segmented Stator Laminations

Plastic injection molding insulation plays a crucial role in enhancing the performance and efficiency of segmented motor stator stacks. This manufacturing process involves injecting molten plastic into a mold to create precise and customized insulation components for the stator stacks. The insulation serves as a protective layer, preventing electrical interference and ensuring optimal functioning of the motor.

The segmented design of the stator stacks allows for efficient assembly and disassembly, facilitating maintenance and repairs. Additionally, plastic injection molding enables the production of intricate and complex insulation shapes, ensuring a seamless fit within the motor components.

This method not only contributes to the overall durability and longevity of the motor but also streamlines the manufacturing process for segmented motor stator stacks.

Winding for Stator Segmented Silicon Steel laminations

Winding for T-shaped stator segmented laminations involves the strategic arrangement of conductive wire around the coated laminations to create electromagnetic fields in electric devices. This winding process is critical in the construction of transformers and motors, where copper wires are systematically wound to generate the desired magnetic flux.

The winding configuration is carefully designed to achieve optimal efficiency and performance. Precise placement of coils on the segmented laminations allows for controlled electrical currents, ensuring the conversion of electrical energy with minimal losses.

OUR SERVICES

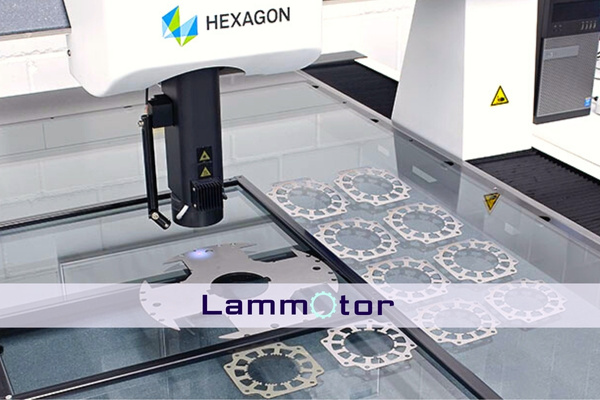

Quality Control for Segmented Stator Lamination Stacks

- Dimensional Accuracy: Verify precise measurements of each segment for proper assembly.

- Coating Integrity: Inspect the electrostatic epoxy coating for uniformity, adhesion, and absence of defects.

- Welding/Bonding Inspection: Ensure the integrity of welded or bonded joints, checking for any imperfections.

- Winding Continuity: Verify the proper placement and connectivity of winding coils.

- Packaging Integrity: Ensure secure packaging to prevent damage during transportation and handling.

FAQs

Segmented stator laminations are individual pieces of electrical steel assembled to form the stator core in electric motors.

Crucial for minimizing energy losses, they enhance motor efficiency by reducing eddy current losses and improving magnetic performance.

Segmented stator laminations offer multiple benefits, including enhanced motor efficiency by minimizing eddy current losses, improved heat dissipation, and optimized magnetic performance.

These advantages collectively contribute to superior motor performance and extended operational life.

Yes, we offer customization options to tailor segmented stator laminations according to specific motor types and sizes.

Clients can choose from various dimensions, coatings, and stacking methods to meet their unique requirements, ensuring optimal performance in diverse applications.

Our segmented stator laminations find applications across various industries, benefiting electric motors in sectors such as automotive, industrial, and renewable energy.

From small motors to larger industrial applications, our laminations cater to a diverse range of electric motor types.

Looking For a Segmented Stator Core Lamination China Manufacturer?

Seeking a reliable source for high-quality segmented stator core laminations? Look no further. Our China-based manufacturing ensures precision, customization, and top-notch quality. Whether you require tailored solutions for specific motor types or standard laminations for diverse applications, we’ve got you covered.

With cutting-edge technology and stringent quality control, we guarantee optimal performance and efficiency for your electric motors. Elevate your motor designs with our superior stator and rotor laminations. Contact us today to discuss your requirements and benefit from the expertise of a trusted manufacturer.