Stator & Rotor lamination stacks for DC motors Manufacturer In China

As a leading China manufacturer of lamination stacks for DC motors, we at our company pride ourselves in our ability to customize our products to meet the unique requirements of our clients. With extensive experience and expertise in this field, we are committed to providing high-quality, efficient, and reliable motor components that can make a real difference to the performance of your DC motors.

Stator and rotor lamination stacks are crucial components in constructing DC motors. They are responsible for converting electrical energy into mechanical energy, thereby powering various machines, from small appliances to heavy industrial equipment.

design and manufacture stamping molds

We specialize in designing and manufacturing stamping molds for motor core lamination. We offer mold designing services that allow us to create a wide range of custom shapes and sizes, ensuring that your motor core lamination needs are met quickly and effectively.

Our experienced technicians can provide additional fabrication services such as machining, welding, and surface treatments to further personalize the product according to your specification.

customized lamination stacks for DC motor cores

We are a DC motor core lamination stack manufacturer specializing in producing high-quality electric cores for all motors. We produce various motor lamination stacks for automotive, aerospace, and industrial applications. And we offer our customers a wide range of services to ensure they get the best results from their motor core laminations.

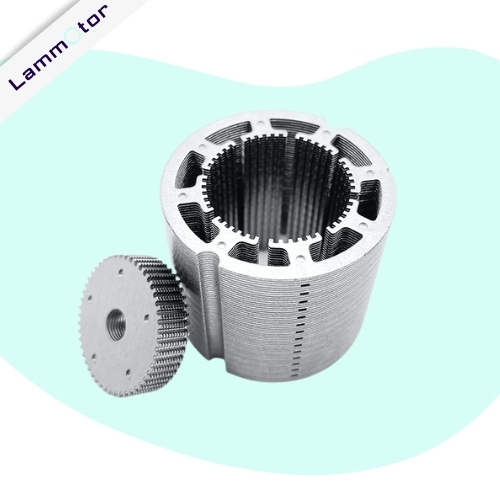

DC motor lamination stacks

The DC motor can provide high torque and speed levels, making them ideal for applications requiring precise control, such as robotics and industrial automation.

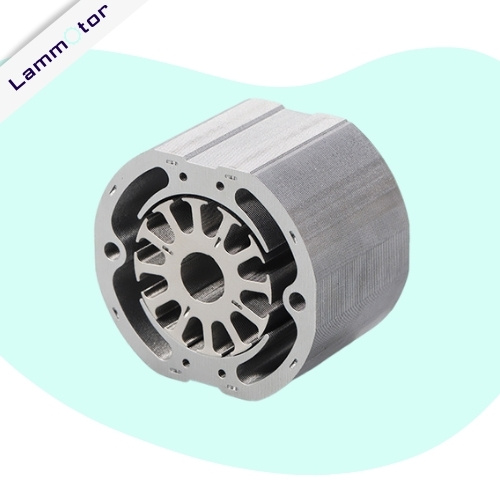

DC stator lamination stacks

DC stator core is an essential component of a brushless DC motor. It is characterized as a soft magnetic material that forms the electromechanical structure of the motor.

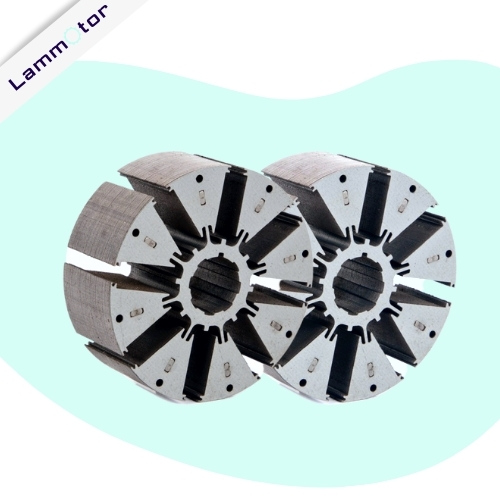

6 Slot Circular DC motor lamination stacks

The 6 Slot Circular DC Motor core consists of six slotted cores arranged in a circular pattern around the central shaft.

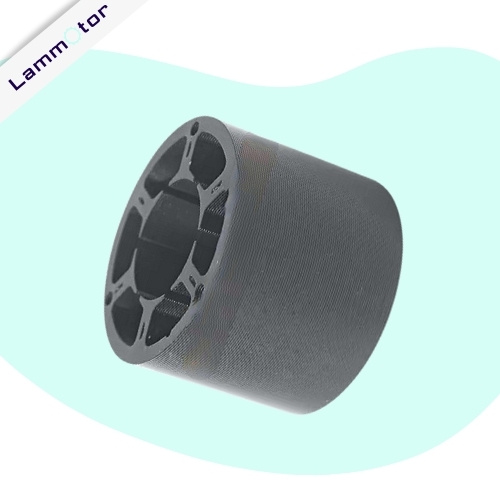

Induction BLDC motor lamination stacks

It uses an induction current to create rotational motion and is one of the most efficient motors.

OUR SERVICES

why choose us for DC Motor Rotor Stator lamination stacks?

Design & Development

According to customer requirements, we can design and develop the motor rotor stator lamination stack for new energy vehicle motors.

Production Capacity

We have production facilities equipped with the latest machinery to ensure high quality, accuracy, and productivity levels. Our production capabilities include stamping, laminating, welding, and assembly.

Quality Control

We have strict quality control procedures to ensure each motor core meets customer specifications and industry standards. Our raw materials are rigorously tested for quality before being used in production.

lamination stacks for other motors

We have extensive experience designing and manufacturing lamination stacks for these motors, and we ensure that the laminations meet the performance requirements of each motor type.

DC Motor core lamination FAQs

What are the applications of DC motor core?

The most common application for DC motor cores is in the operation of everyday household items such as vacuum cleaners, washing machines, and dishwashers.

These motors offer a reliable power source and require minimal maintenance over time.

Additionally, DC motor cores can be used in higher-powered industrial machineries such as cranes or conveyor belts where more torque is needed to lift heavy objects.

Furthermore, they can also be found in automotive engines and medical equipment like wheelchairs and prosthetics.

DC motor core VS. AC motor core

The debate between DC and AC motors often rages regarding industrial motor cores.

DC motor cores are generally more reliable than AC motors in terms of initial installation and maintenance costs.

They do not require complicated circuitry or extra components such as transformers, thus simplifying the system design process.

Additionally, DC motors can be tuned by adjusting the voltage applied to the windings; this allows for precise control of the speed and torque output of the motor.

On the other hand, AC motors are typically cheaper than DC motors due to their simpler construction.

Furthermore, they tend to be more efficient under heavy loads as well as lighter loads when compared to DC motors.

Let’s get started on your lamination stacks project!

Are you looking to get started on a project involving a DC motor core? This can be daunting, but with the right knowledge and guidance, your project will be up and running in no time.