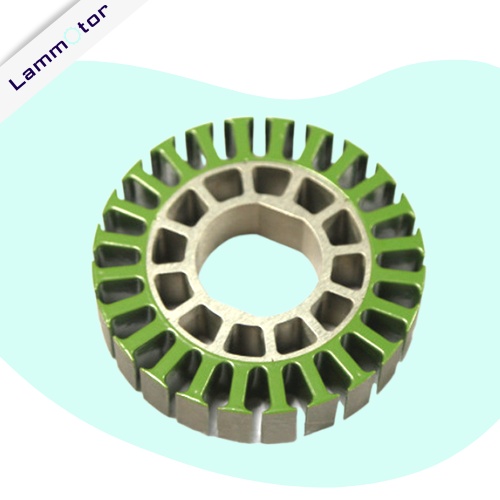

Stator Lamination Stacks Manufacturer in China

As a stator laminations China manufacturer, we specialize in customizing various sizes and thicknesses of motor stator laminations to meet our client’s specific requirements. Our team of experts is highly knowledgeable and skilled in producing high-quality stator laminations that are durable, reliable, and efficient.

We use advanced stamping equipment and techniques to ensure precision and accuracy in the manufacturing process, and we prioritize quality control at every stage of production. Whether you need stator laminations for AC motors, DC motors, or generators, we can provide customized solutions that meet your needs and exceed your expectations.

Contact us today to learn more about our services and how we can help you with your stator and rotor lamination needs.

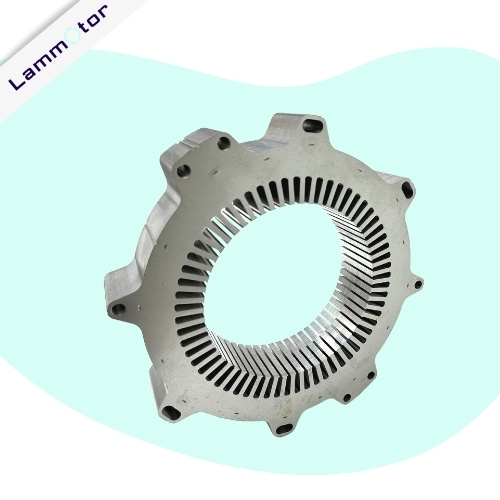

Stator Core Laminations Stamping

Stamping stator laminations allows for high-volume production, consistent quality, and accuracy with tight tolerances. We provide progressive stamping, compound stamping, and rotary notching.

The stamped laminations are typically stacked together to create the stator core, which forms the foundation of an electric motor. The use of stamped stator laminations ensures efficient energy transfer, reduces eddy current losses, and increases the overall performance and longevity of the motor.

As a leading electrical steel laminations China manufacturer, we specialize in stamping stator laminations that meet our client’s specific needs and requirements, ensuring high-quality products that are durable and reliable.

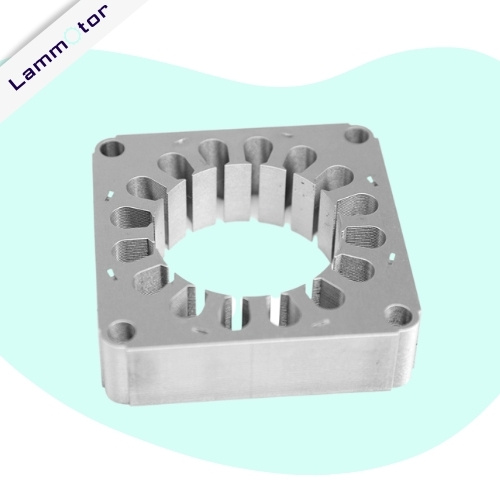

Laser Cutting Stator Laminations

Laser-cutting lamination is a highly effective method for producing stator laminations for electric motors and generators. In this process, a laser beam is directed onto a thin sheet of metal to cut out the required shapes and sizes. The accuracy of the cuts ensures that the laminations fit together perfectly, reducing energy losses due to gaps.

With advanced software and automation, we can quickly and accurately cut out the required shapes with minimal waste. And we ensure that each lamination is identical and meets the required specifications. This makes it an ideal option for rapid prototyping motor laminations, as it allows for easy customization and iteration of designs.

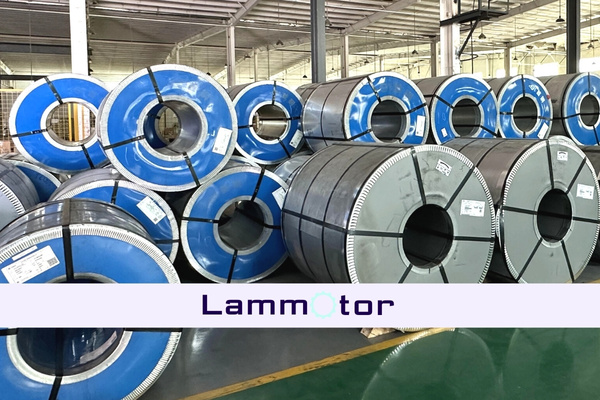

Materials Used in Stator Lamination Stacks

There are several types of electrical steels used for manufacturing stator lamination stacks, including:

Silicon Steel

Silicon steel is the most common material used for stator lamination stacks due to its low cost, high magnetic permeability, and low core loss.

Non-oriented Electrical Steel

Non-oriented electrical steel has a uniform crystal structure that allows it to maintain its magnetic properties under varying directions of magnetization.

Grain-Oriented Electrical Steel

Grain-oriented electrical steel is composed of crystals that are aligned in one direction, making it ideal for applications where the magnetic flux is consistently oriented in one direction.

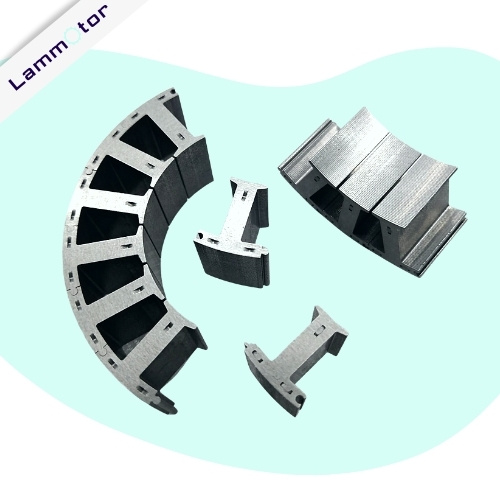

A series of motor Stator laminations customized

As a manufacturer of motor stator laminations, we have the ability to produce various types of stator laminations, including segmental laminations. We utilize different manufacturing processes such as stamping, laser cutting, and wire EDM to create precise and high-quality laminations for various applications.

With our expertise and equipment, we are capable of producing customized stator laminations that meet the unique requirements of our clients. Whether it’s a high-volume production or a small batch, we can deliver the desired results with precision and efficiency.

Comprehensive Testing Services

quality control for stator laminations

To ensure the quality of stator laminations, it is important to implement several measures throughout the manufacturing process.

We use CMM to accurately measure the dimensions of the laminations and verify their conformity to the design requirements.

We provide inspection reports at various stages of the manufacturing process.

Various tests on the finished laminations, such as core loss testing and magnetic flux density testing.

OUR SERVICES

Why Choose Us as Your stator and rotor laminations China manufacturer?

With years of experience in the industry, we have established ourselves as a trusted and reliable supplier of stator laminations to a wide range of customers.

When you choose us as your stator lamination manufacturer, you can be confident that you are getting the highest quality products and exceptional customer service.

high-quality materials

Firstly, we use only high-quality silicon steel materials in the production of our stator laminations to ensure that they are durable and long-lasting.

quality control

Additionally, we have a rigorous quality control process in place to ensure that every product that leaves our facility meets our high standards for accuracy and precision.

Manufacturing Capabilities

Our stamping capabilities are also top-notch, allowing us to produce large volumes of laminations quickly and efficiently while maintaining consistent quality.

Motor Stator Laminations FAQs

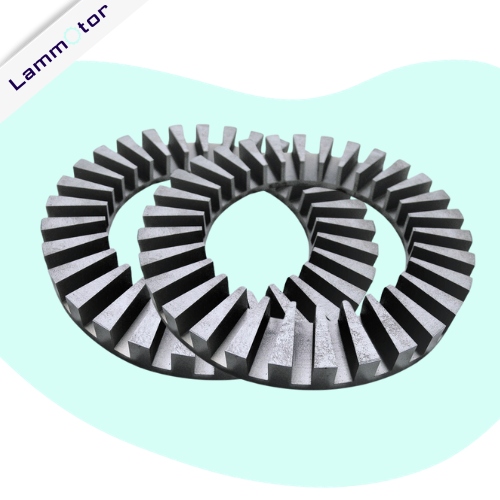

Stator lamination stacks are core components of electric motors and generators that consist of thin sheets or laminations made from various electrical steels.

The stator lamination stack is responsible for producing the magnetic field that interacts with the rotor to induce motion in an electric motor or generator.

Thus, the performance and efficiency of an electric motor or generator depend largely on the quality and composition of its stator lamination stack.

Stator laminations are typically joined together through a process called stacking. The laminations are stacked one on top of the other and then clamped tightly together using bolts or metal straps.

The clamping force helps to ensure tight contact between the laminations, which is important for reducing magnetic losses and improving the performance of the motor or generator.

In some cases, an adhesive may also be used to bond the laminations together. The method of joining the laminations together can vary depending on the specific application and design requirements.

Welding is also one of laminations stacking methods.

Stator lamination stacks are used in various types of electric motors, transformers, and generators.

A. Electric Motors:

Stator lamination stacks are used in various types of electric motors, including:

AC Motors:

AC motors use stator cores to convert electrical energy into mechanical energy by rotating a magnetic field.

DC Motors:

DC motors use stators to produce a magnetic field that interacts with the rotor to produce rotational motion.

Synchronous Motors:

Synchronous motors use stators to synchronize the rotation of the rotor with the frequency of the AC power supply.

Induction Motors:

Induction motors use stator laminations to induce a current in the rotor through electromagnetic induction, producing rotational motion.

B. Generators:

Stator core lamination stacks are also used in various types of generators, including:

Wind Turbine Generators:

Wind turbine generators use stator core lamination stacks to convert kinetic energy from the wind into electrical energy.

Hydroelectric Generators:

Hydroelectric generators use them to convert potential energy from falling water into electrical energy.

Gas Turbine Generators:

Gas turbine generators use them to convert thermal energy from burning fuel into electrical energy.

A. Core Losses:

Core losses refer to the energy lost due to hysteresis and eddy currents in the stator lamination stack, leading to inefficiencies in the motor or generator.

B. Magnetic Flux Density:

The magnetic flux density within the stator lamination stack determines its ability to produce a magnetic field and interact with the rotor.

C. Hysteresis Losses:

Hysteresis losses occur due to the resistance of the electrical steel to magnetization and demagnetization, leading to energy losses in the form of heat.

D. Eddy Current Losses:

Eddy current losses occur due to the flow of electrical current through the laminations, producing heat and leading to inefficiencies.

When selecting a reliable stator lamination China manufacturer, it’s important to consider a number of factors to ensure that you find a high-quality supplier. Here are some key points to keep in mind:

Look for experience:

Choose a manufacturer with a proven track record of producing quality stator laminations for a range of applications.

Check certifications:

Ensure that the manufacturer has the necessary certifications and approvals from industry bodies such as ISO or UL, demonstrating their commitment to quality standards.

Quality control processes:

Ask about the company’s quality control processes, including inspections and testing, to ensure that their products meet your specific requirements.

Customization capabilities:

Find a manufacturer who can customize their products to your needs and specifications, allowing you to create unique solutions that meet your exact requirements.

By following these guidelines, you can select a reliable stator lamination China manufacturer that will provide you with high-quality products and excellent service.

Need to stamp electric motor Stator laminations? Contact Us!

If you are in need of stamping electric motor stator laminations, don’t hesitate to contact us! Our team of experts has years of experience in the field and can provide you with high-quality stamped stator laminations that meet your specific requirements.

We use advanced stamping technology to ensure precision and accuracy, and we offer competitive pricing and quick turnaround times. Contact us today to learn more about our services and how we can help you with your stator lamination needs.