prototype Motor Lamination Stacks in china

Prototyping motor lamination stacks is a critical part of the development process for many electric motors. We offer the highest quality prototype motor lamination stacks services for clients. Our experienced team has extensive experience designing and manufacturing custom motor laminations of any size or shape.

Our prototype lamination stacks services include die designing, precision laser cutting, and wire EDM. With our wide variety of services, we can guarantee that you will find the perfect solution for your needs.

prototyping motor lamination Stacks

Rapid prototyping is a cost-effective way to produce prototype laminations of various materials. These materials can include cobalt alloys, cold-rolled motor lam, nickel alloys, silicon steels, and others. With rapid prototyping capability, our clients can quickly receive feedback on their designs before entering into full production runs.

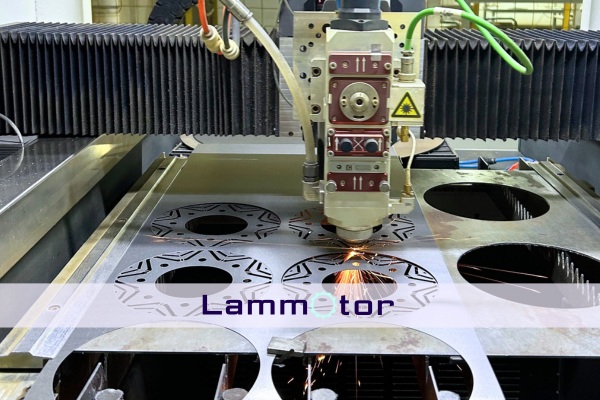

laser cutting lamination

Laser-cutting motor lamination is an advanced technology for rapid prototype motor lamination. This method of manufacturing motors allows for greater flexibility and accuracy in production. We can quickly and efficiently create precise shapes from various materials through laser cutting. Meanwhile, it produces small burr-free edges with no material loss.

wire EDM lamination

Wire EDM cutting is a reliable and cost-effective method to produce motor lamination prototypes. This technology utilizes electrical discharge machining (EDM) to cut the laminates and weld them together in a permanent bond. Wire EDM lamination offers many advantages, such as high accuracy, repeatability, low cost, and minimal tool wear.

Comprehensive Testing Services

quality control

Quality control of motor lamination stacks is vital in ensuring that the end product is of desired quality.

Our quality control teams inspect motor laminations to meet the necessary standards and requirements. And our testing equipment includes a projector, CMM, drawing force, etc.

Our automated press lines undergo rigorous quality control tests before the electrical steel is stamped into motor laminations. These steps ensure that each stamping is uniform in thickness and shape, ensuring high-quality laminations.

No matter what stamping mode, we will test the first few pieces of the motor lamination stack and the first few groups of the stator stack, and the batch production can only be carried out after the test is qualified.

Materials used in prototyping motor lamination Stacks

Cold-rolled steel is a popular material for prototype laminations. It has good electrical properties and high strength, making it a reliable and cost-effective base material.

Silicon steel is considered the next best option for prototype electrical steel laminations. It is corrosion-resistant, lightweight, and strong. Also, its electrical conductivity makes it an easy material to work with in complex circuitry.

M15-M45 alloys are also great for prototype laminations due to their high tensile strength, durability, and favorable electrical properties.

Finally, nickel alloys are also a great choice for prototype laminations due to their high corrosion resistance, good electrical conductivity, and low cost. They are also easy to form into desired shapes.

OUR SERVICES

Why choose our prototyping motor lamination Stacks services?

We can provide custom solutions for any lamination needs. Besides standard motor stator and rotor lamination, we can also produce customized laminations.

Manufacturing Capabilities

We offer and support a wide range of manufacturing capabilities to meet your rapid prototyping needs. We also provide secondary services such as annealing, stacking, and welding.

24/7 Engineering Support

We offer fast and reliable turn-around times. Our team is available 24/7 to answer any questions you might have. We are backed by a 100% satisfaction guarantee, which means we’re committed to providing you with the best possible service.

Fast Lead Time

Laser cutting or wire EDM can be suitable for immediate lamination needs. The normal turnaround time for prototype cores is three weeks, which allows you to test your design before manufacturing it in larger quantities.

Need to prototype electric motor lamination stack?

We are a motor lamination manufacturer in China. We provide short turnaround times and high-quality motor stator and rotor lamination. And we can offer prototyping services for electric motor lamination and other motors, such as DC motors, AC motors, synchronous motors, asynchronous motors, geared motors, stepper motors, and servo motors. With our help, you can easily prototype your motor lamination cost-effectively.