Drone Motor Cores Stator Rotor Laminations in China

At the heart of every drone’s functionality is its motor core, and the quality of this core significantly influences the drone’s efficiency, flight time, and overall reliability. High-quality motor cores must be meticulously crafted, especially those designed for drones. Our drone motor cores are designed to cater specifically to the dynamic demands of modern drones.

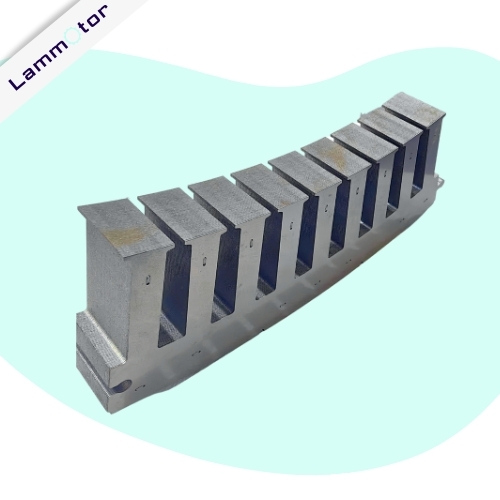

Drone Motor Stator Rotor Ready Molds

We have professional engineers to develop and draw mold drawings. and have multiple Western Japan slow wire machines, with mold processing accuracy reaching 0.002MM.

In addition, there are currently more than 400 sets of stamping molds and multiple open public stamping molds for UAV stators.

If you would like to purchase existing standard-size drone motor stators, please contact us today for a list of drone stator products.

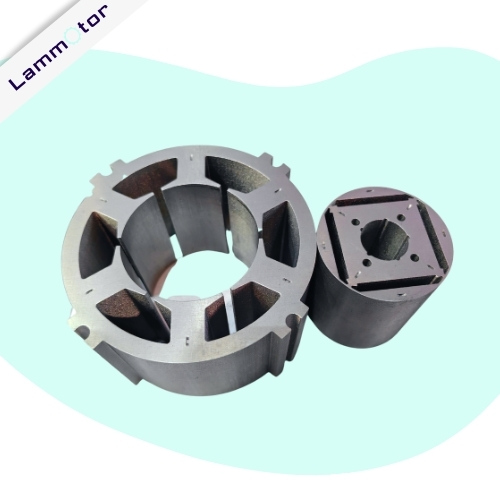

Custom brushless Stator Rotor Laminations for Drones/Aircraft/Aviation Models

We have been collaborating with DJI, the drone manufacturer, for over 10 years. Every year, we supply them with 4 million sets of motor iron cores. These iron cores are used in various DJI drone models, including those for public safety, surveying and mapping, power, oil and gas, agriculture, and more.

The following are the various types of UAC motor stator cores that we have manufactured:

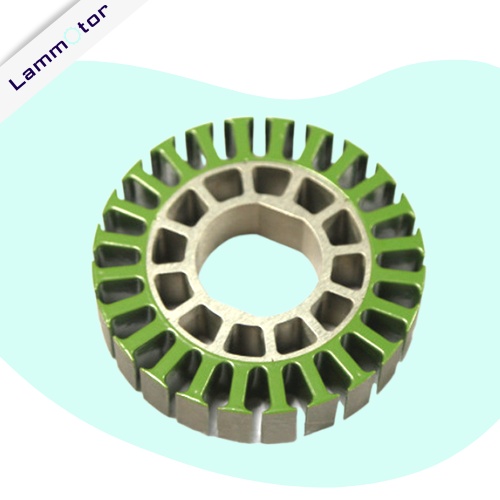

UAC Motor Lamination Epoxy Coating

The coating is a common preparation method for motor cores using internally applied epoxy polyester powder coating. Its main component is epoxy resin. After heating and curing the powder, it forms the desired coating on the surface of the workpiece. This can compress space and improve motor performance.

The cured motor core has the main advantages of a smooth and glossy appearance, free from particles and shrinkage holes, with a controlled thickness of 0.20-0.30mm (adjustable according to customer drawings).

Drone Motor Stator Winding

We provide stator winding services for drone/UAC motors, including manual stator copper wire coil winding for the prototype sample and automatic stator coil winding for mass production.

The number of turns and wire size of the winding can be customized according to customer requirements. Trust us to deliver superior winding services tailored to meet the unique needs of your motor, maximizing efficiency and minimizing downtime.

OUR SERVICES

why choose us for Drone Motor Rotor Stator lamination stacks?

We have Longmen high-speed precision punch 40 sets and have imported from Japan punching machine, a maximum tonnage of up to 300 tons, supporting a number of sets of western Japan slow wire, fast wire, grinding machine, spark machine, and other molding equipment.

With an independent design and development department, mold department, stamping department, coating department, and injection department, can produce self-adhesive samples, at a fast speed, at a low cost.

How Do We Control the Quality?

Our process begins with Material Verification; we ensure that only top-grade silicon steel, tested for its magnetic and mechanical properties, is used.

Continuous monitoring during the production phase ensures real-time detection and correction of anomalies. Post-production, each core undergoes a stringent quality check, encompassing aspects like dimensional accuracy, magnetic flux, and potential defects.

Also, has passed ISO9001 international quality management system and TS16949 and ISO14001 certification.

Other Products

Drone motor Cores FAQs

Brushless motors, commonly used in drones, don’t use brushes for communication, which reduces friction and wear. This results in higher efficiency, longer lifespan, and less maintenance. In contrast, brushed motors use brushes, making them simpler but less efficient and durable.

Drones, especially the multirotor variety commonly used for photography, surveillance, and recreational purposes, employ specific motors to achieve flight. Here are the primary types of motors used in drones:

Brushless DC Motors (BLDC):

Advantages: These are the most common types of motors used in modern drones. They are more efficient than brushed motors because there’s no physical contact between different parts, resulting in less friction, less heating, and a longer lifespan. They also offer better performance, reliability, and lifespan. BLDC motors are quieter and require less maintenance than brushed motors.

Disadvantages: They are generally more expensive and require electronic speed controllers (ESC) to operate, which can add to the overall cost.

Brushed DC Motors:

Advantages: These motors are simpler and typically cheaper than brushless motors. They were used in earlier drone models and are still in some toy drones.

Disadvantages: Brushed motors have brushes that wear out over time, resulting in a shorter lifespan. They can also be less efficient than brushless motors and produce more noise.

Stepper Motors:

Usage: These are not typically used for drone propulsion but can be found in some specialized applications like camera gimbals for precision control.

Advantages: They offer precise control because they move in discrete steps.

Disadvantages: They are generally less efficient than BLDC motors and can be bulkier.

Coreless Motors:

Usage: These are used in very small drones or nano drones.

Advantages: They are lightweight and provide a quick response, making them suitable for tiny drones.

Disadvantages: They tend to have a shorter lifespan compared to BLDC motors.

Permanent magnet motors employ permanent magnets to produce the required magnetic fields. This design minimizes energy loss, offers excellent torque, and provides consistent power. Their superior efficiency ensures drones consume less energy, leading to extended flight times.

Yes, you can use AC motors for drones, particularly the AC brushless motors, also known as Permanent Magnet Synchronous Motors (PMSM). Drones commonly utilize brushless motors, and there are two main types: DC brushless motors (BLDC) and AC brushless motors (BLAC or PMSM).

Both types offer efficiency, longevity, and maintenance advantages over traditional brushed motors. While BLDC motors use trapezoidal waveforms and are more common in hobbyist drones due to their simplicity and ease of control, BLAC or PMSM motors use sinusoidal waveforms and can offer smoother operation.

Let’s get started on your motor lamination project For Drone and UAV!

Please get in touch with us if you have any questions or concerns about our products or services. We will be happy to assist you!