Compressor Motor Core Lamination in China

We are a leading motor core lamination manufacturer in China, specializing in the customization of lamination stacks for various compressor motors, including air conditioner compressor motors, refrigerator compressor motors, and oil-free air compressor pumps.

Our materials are supplied directly by Chinese suppliers Baosteel, Shougang, and WisCO. With the right design and rich experience in mold development, we can guarantee quality. It will save time if you can provide us with the drawings of the stator rotor in advance. If you also need die cast rotors, please also provide drawings of aluminum die casting.

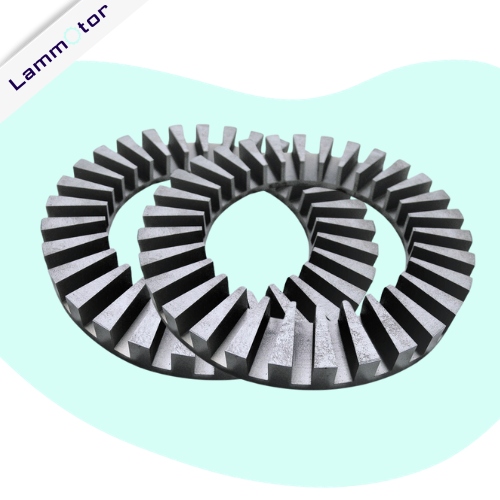

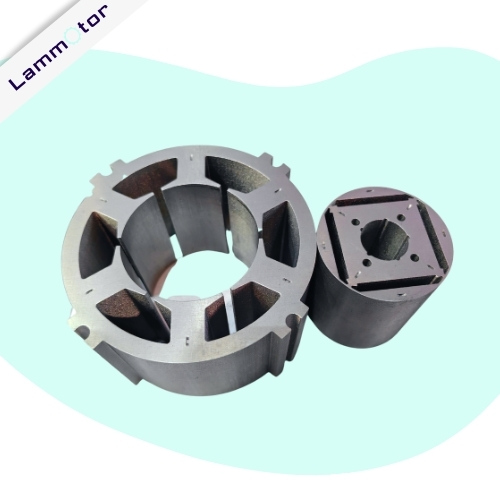

Customize Motor Lamination Stacks for Compressors

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. The core components of a compressor are the motor stator and rotor, which play a crucial role in its operation by generating the magnetic fields needed to drive the compressor.

These components are essential for various applications, including air conditioners, refrigerators, oil-free air compressors, and industrial machinery, where efficient and reliable performance is critical.

Manufacturing Capability of Compressor Motor Lamination

Our comprehensive manufacturing capabilities for compressor motor stator and rotor laminations ensure that we meet the highest standards of quality and precision.

Mold Design and Manufacturing

We begin with expert mold design and manufacturing, using advanced CAD/CAM software and precision machining techniques. This ensures that every mold we produce meets exact specifications, crucial for the high precision required in compressor motor laminations.

Stamping (Progressive and Compound)

We provide progressive stamping and compound stamping methods. This allows us to produce complex and high-precision laminations efficiently, ensuring consistency and accuracy across large production runs.

Lamination Stacking

We offer multiple lamination stacking methods, including interlocking, laser welding, and cleating. These processes ensure that the laminations are securely and accurately assembled, contributing to the overall efficiency and durability of the compressor motor.

Rotor Die Casting

In the die casting process, molten metal—usually aluminum or copper—is injected into a precisely machined mold that forms the rotor’s shape and the conductive bars within it.

Other Products

FAQs

Compressor motors are typically AC (Alternating Current) motors. AC motors are preferred for compressor power drives due to their efficiency and reliability, making them ideal for applications such as air conditioning compressors, hydraulic systems, and irrigation pumps.

Their ability to handle varying load conditions and provide consistent performance makes them the standard choice in these applications.

Compressor motors are used in a variety of applications across different industries:

HVAC Compressors: Powering air conditioning systems for residential, commercial, and industrial spaces.

Refrigeration Compressors: Essential for cooling in refrigerators and freezers, both commercial and domestic.

Automotive Compressors: Used in vehicle air conditioning systems and air suspension systems.

Industrial Compressors: Driving heavy-duty equipment in manufacturing, oil and gas, and other industrial processes.

An air conditioner’s compressor is the heart of the cooling system. It works by compressing refrigerant gas, raising its temperature and pressure.

The hot, high-pressure gas then flows through the condenser coils, where it releases heat and condenses into a liquid. This liquid refrigerant then moves to the evaporator coils inside the home, where it absorbs heat as it evaporates back into a gas, cooling the air.

The compressor continuously cycles the refrigerant through this process, maintaining the desired indoor temperature by removing heat from the air and expelling it outside.

Looking for a Compressor Motor Lamination China Manufacturer?

If you’re searching for a reliable and experienced manufacturer of compressor motor lamination in China, you’ve come to the right place. Whether for HVAC, refrigeration, automotive, or industrial applications, our precision-engineered laminations ensure optimal performance and durability.

If you want to customize the compressor stator and rotor, please feel free to contact us. Before mass production, we can laser cut or wire cut samples. Sample delivery time is 30 days after confirmation of specifications, such as drawings, material grades, die casting types, tolerances, etc.