Motor laminations are crucial components in electrical motors, which make them work efficiently. Motor lamination stamping dies are responsible for producing these important components. Hence, it is essential to maintain these dies regularly. This guide will help you understand how to maintain motor lamination stamping dies correctly.

What Are Motor Lamination Stamping Dies?

Motor lamination stamping dies are tools used to create motor stator and rotor laminations using sheets of special silicon steel. There are several methods of motor lamination stamping, so there are different types of stamping dies.

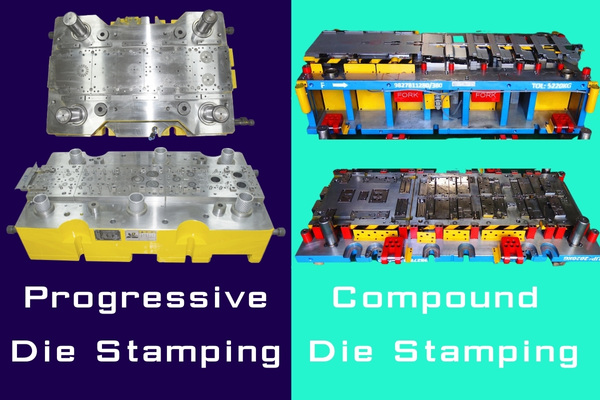

There are two types of dies used in the motor industry: progressive and transfer dies. Progressive dies produce several lamination shapes simultaneously, whereas transfer dies to make individual parts in separate stations. We also have compound stamping dies.

Common problems with motor lamination stamping die include cracks, dents, wear, and misalignment. Therefore, we provide some tips on how to maintain stamping molds.

Some Tips On How To Maintain Stamping Dies:

Motor lamination stamping dies are an essential tool for the manufacturing of electric motors. These dies help shape thin sheets of metal into precise shapes that are used to create the core of an electric motor. Proper maintenance of these tools is necessary to ensure their longevity and performance. Here are some tips on how to maintain metal stamping dies:

Maintenance During Die Installation

Proper installation of the die is essential for its longevity and performance. Here are some tips to maintain stamping dies during installation:

Check the condition of the die during installation: Before the installation process begins, make sure the die is in good condition. Check for any cracks, chips, or signs of wear.

Use proper lifting equipment: Stamping dies can be heavy, so use proper lifting equipment to avoid damage during the installation process.

Align the die properly: Ensure that the die is aligned correctly before tightening the bolts to avoid any damage caused by misalignment.

Clean the mold after each use

It is essential to keep the mold clean after each use. Residual material can build up and cause damage to the mold’s surface.

Lubricate the mold regularly

To prevent wear and tear on the mold, it is crucial to lubricate it regularly. Use a high-quality lubricant that is compatible with the type of mold material.

Inspect the mold for damage

Regular inspections of the mold can help you detect any damage or wear before it becomes a more significant issue. Look for cracks, chips, or signs of wear on the mold.

Check the upper and lower molds regularly

Regularly check the alignment of the upper and lower die seats of the rotary table. If the die position of the punch is not aligned, the speed of the die will be accelerated and the processing quality will be poor.

Store the mold properly

When not in use, store the mold in a dry, cool place to prevent rust or other forms of corrosion.

Replace damaged or worn parts

If you notice any damage or wear on the mold, replace the affected parts as soon as possible. This can help prevent further damage to the mold and improve its longevity.

Parts of the mold to maintain include:

Die plate: The die plate is the main component of the mold, and it must be kept clean and lubricated.

Punches and dies: These parts should be inspected and replaced if they show signs of wear or damage.

Bolsters and wedge blocks: These components hold the punch and die in place and must be checked for wear and lubricated regularly.

Springs: Check springs for proper tension and replace them if they lose strength over time.

Guides and guide pins: These parts ensure that the punch and die align correctly during the stamping process. Regular inspection and lubrication are vital to maintaining their performance.

By following these maintenance tips, you can extend the life of your motor lamination stamping dies and ensure consistent, high-quality stamping results.

Maintenance Checklist for Motor Lamination Stamping Dies

The following are essential maintenance tasks that you should carry out on your motor lamination stamping dies:

Daily maintenance:

Inspect the die surface and its working environment for debris

Check the air pressure system

Clean the die-cutter and surrounding areas

Weekly maintenance

Examine the die-cutting edges

Lubricate the punch and die

Check the status of the safety devices

Monthly maintenance

Inspect the entire die for loose or missing parts

Repair any worn-out components

Verify the correct alignment of the die and punch

Annual maintenance

Replace any worn-out parts

Upgrade the die’s software

Check the cutting speed and quality of cut lamination

Cleaning Techniques for Motor Lamination Stamping Dies

Cleanliness is vital in maintaining motor lamination stamping dies. When cleaning the dies, follow these steps:

First, remove all debris from the die surface.

Use a biodegradable cleaner to clean the die’s interior.

Wipe down the exterior of the die with a clean, dry cloth.

Lubricate the die cutter and its components.

Storage and Handling of Motor Lamination Stamping Dies

To Store And Handle Motor Lamination Stamping Dies Correctly:

Use a dry storage area with low humidity and temperature fluctuations.

Cover the dies with protective covers to prevent dust accumulation.

Store the dies in a vertical position.

Transport the dies using specialized equipment.

Troubleshooting Motor Lamination Stamping Dies

When you experience problems with your stator and rotor lamination stamping dies, follow these steps:

Identify the issue by examining the damaged parts.

Correct the problem by repairing or replacing any worn-out or damaged components.

Seek professional assistance if the problem persists.

The Maintenance in Production

During production, regular maintenance of the stamping die is necessary to ensure its optimal performance. Here are some tips for maintaining the die during production:

Clean the die regularly: Regular cleaning of the die is essential to prevent material buildup and corrosion. Use a soft cloth or brush to clean the die after each use.

Lubricate the die regularly: Lubrication helps reduce friction and wear on the die. Use a high-quality lubricant recommended for the type of die material.

Inspect the die regularly: Regular inspections of the die can identify any damage or wear before it becomes a more significant issue. Look for cracks, chips, or signs of wear on the die.

Conclusion

Maintaining motor lamination stamping dies is crucial for ensuring the efficient production of motor laminations.

The maintenance checklist, cleaning techniques, storage and handling tips, and troubleshooting steps provided in this guide will help keep your motor lamination stamping dies in excellent condition.

By following these guidelines, you can extend their lifespan and achieve high-quality motor laminations. If you want to learn more about rotor and stator laminations, contact us now!

How Often Should Stamping Dies Be Inspected?

Generally, you need to check the mold once a week, or the mold is used more than five million times.

Stamping dies should be inspected regularly to ensure their proper function and longevity. Ideally, they should be inspected after each use to identify any issues before they become more severe and cause damage or failure of the die.

Regular inspections can help detect signs of wear, corrosion, or material buildup, which can impair the die’s performance. If left unchecked, these issues can lead to costly repairs or replacement of the die.

By inspecting stamping dies regularly, manufacturers can keep them in good condition and minimize downtime due to unexpected failures.

How Can I Ensure The Proper Alignment Of Stamping Dies During Installation?

First, check the mating surfaces of both the die holder and the die to ensure they are clean and free of debris or damage.

Next, use precision measuring tools such as dial indicators to ensure the die is level and aligned with the machine’s main ram. It is important to make sure the die is securely fastened in place using bolts and clamps to prevent any movement or shifting during operation.

Finally, perform a test run to confirm the die is properly aligned and functioning before starting production runs.

Regular maintenance checks can also help ensure the continued alignment of the stamping dies over time.