Why do some electromagnetic components work reliably in very weak magnetic fields, while others struggle with stability and accuracy?

The answer often lies in the material. If you are designing sensitive magnetic circuits or compact electromagnetic devices, understanding ferro-nickel 1J50 material is essential.

In this article, we explain what 1J50 is, why it matters, where it is used, and how 1J50 cores are manufactured in real production.

What Is Ferro-Nickel 1J50 Material?

1J50 is an iron–nickel alloy with a nickel content of approximately 45–55%. It combines high saturation magnetic flux density with good initial permeability, making it suitable for applications that require stable magnetic performance.

The saturation magnetic flux density of 1J50 is about 1.55 T, while its initial permeability is around 0.42 mH/m². Compared with other ferro-nickel alloys, 1J50 offers relatively higher saturation flux density.

After low-temperature annealing, its magnetic performance improves further. Following final heat treatment, the alloy forms a clear cubic crystal structure. The hysteresis loop becomes close to rectangular, and the residual magnetic flux density can reach up to 1.5 T.

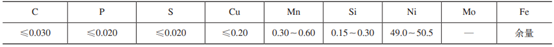

Chemical Composition of 1J50

Mechanical Properties of 1J50

| Property | Unit | Value |

| Electrical Resistivity | μΩ·m | 0.45 |

| Density | g/cm³ | 8.2 |

| Curie Temperature | °C | 500 |

| Saturation Magnetostriction Coefficient | ×10⁻² | 25 |

Mechanical Strength Properties

| Property | Condition | Value |

| Brinell Hardness (HBS) | Cold-worked | 170 |

| Annealed | 130 | |

| Tensile Strength (MPa) | Cold-worked | 785 |

| Annealed | 450 | |

| Yield Strength (MPa) | Cold-worked | 685 |

| Annealed | 150 | |

| Elongation (%) | Cold-worked | 3 |

| Annealed | 37 |

Material Properties of Ferro-Nickel 1J50

The density of 1J50 is approximately 8.2 g/cm³, and its Curie temperature is around 500°C. Its most notable characteristics are high permeability and high saturation magnetic flux density.

Excellent Magnetic Performance

- High permeability

Ferro-nickel 1J50 material shows high initial and maximum permeability under weak and medium magnetic fields. This makes it ideal for magnetically sensitive circuits.

- High saturation magnetic flux density

The saturation flux density reaches 1.5–1.6 T (typical value around 1.56 T), offering balanced performance among soft magnetic alloys.

- Low coercivity

Low hysteresis loss helps improve operational stability and repeatability in magnetic devices.

Typical Applications of 1J50

1J50 is typically used in applications with medium magnetic field strength and high requirements for magnetic performance consistency.

1. Electronics and Instrumentation

- Magnetic cores, magnetic amplifiers

- Recording heads, flux modulators

- Relay magnetic systems

- Magnetic circuit components for ground fault circuit breakers

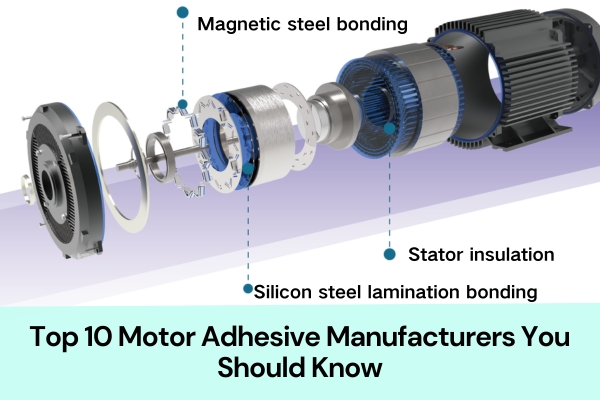

2. Electrical and Automation Equipment

- Small transformer cores

- Electromagnetic coils and electromagnets

- Automatic synchronous motors and miniature motor cores

- Micro motor components used in electronic watches

3. Precision and Specialized Applications

- Sensor magnetic circuits (position, angle, and current sensors)

- Precision magnetic components for aerospace applications

- Defense electronics, radar, and electronic warfare systems

1J50 Core Manufacturing Process

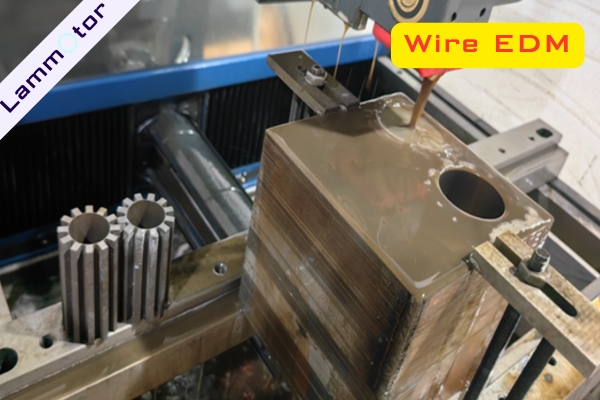

1. Cutting and Forming

Manufacturers usually start with thin sheets of ferro-nickel 1J50 material. Depending on product structure, they choose stamping, laser cutting, or wire cutting for blanking.

For mass production, stamping offers higher efficiency and better dimensional consistency. During prototyping or when dealing with complex geometries, laser cutting and wire cutting provide greater flexibility.

2. Lamination Stacking

After single laminations are produced, the core goes through stacking and assembly. For soft magnetic materials like 1J50, stress control during assembly is critical.

Excessive stacking pressure or improper fixing methods can introduce internal stress. This increases coercivity and reduces permeability. In practical production, manufacturers carefully control stacking pressure and prefer low-stress assembly methods to balance structural stability and magnetic performance.

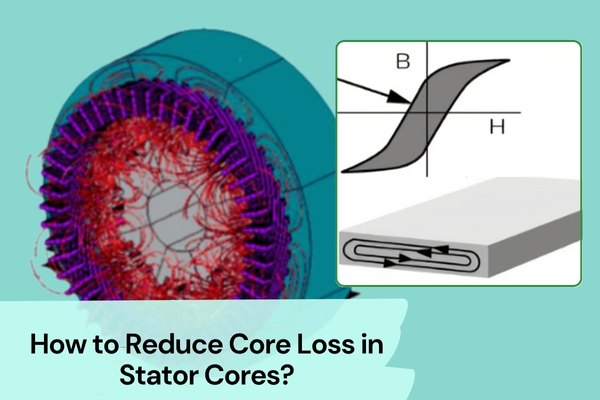

3. Heat Treatment Process

Heat treatment plays a decisive role in achieving the final magnetic performance of 1J50 lamination cores. Improper annealing can significantly reduce permeability and consistency.

After core fabrication, 1J50 must undergo annealing to eliminate machining stress and restore magnetic properties.

Vacuum annealing is commonly used. Parts are heated together with the furnace to around 1100°C, held for a period, and then cooled with the furnace.

According to Chinese national standards, the required magnetic properties of 1J50 include:

- Maximum permeability μm ≥ 31.3 mH/m

- Saturation flux density Bs ≥ 1.5 T

- Coercivity Hc ≤ 14.4 A/m

Annealing atmosphere

Dry hydrogen with dew point ≤ –40°C, or high vacuum with residual pressure ≤ 0.1 Pa

Heating schedule

1100–1150°C, holding time 3–6 hours depending on thickness and structure

Cooling schedule

Slow cooling at 100–200°C/h down to 600°C, then fast cooling below 300°C

Common Types of Permalloy

Permalloy usually refers to iron–nickel alloys with nickel content ranging from 30% to 90%. These alloys are among the most widely used soft magnetic materials.

With proper processing, engineers can achieve extremely high magnetic performance, including initial permeability over 100,000, maximum permeability exceeding one million, very low coercivity, and rectangular hysteresis characteristics close to ideal values.

Common permalloy grades include 1J50, 1J79, and 1J85.

1J50

1J50 has slightly lower saturation flux density than silicon steel, but its permeability is tens of times higher. Core loss is also 2–3 times lower. It works well in higher-frequency transformers (400–8000 Hz) under 100 W, where low no-load current is required.

1J79

1J79 offers balanced performance and suits high-frequency, low-voltage transformers, leakage protection switch cores, common-mode chokes, and current transformer cores.

1J85

1J85 provides extremely high initial permeability, often exceeding 100,000. Engineers typically use it in weak-signal, low- or high-frequency input and output transformers, common-mode inductors, and high-precision current transformers.

Soft Magnetic Materials Commonly Used for Motor Cores

Modern motor core materials include silicon steel, iron–cobalt alloys, amorphous alloys, nanocrystalline alloys, and soft magnetic composites (SMC).

Silicon Steel

Silicon steel is the most widely used motor core material. It consists of iron with approximately 1–3% silicon, plus small amounts of aluminum and manganese.

Non-oriented silicon steel provides isotropic magnetic properties and is suitable for rotating magnetic fields in motors, while grain-oriented silicon steel is mainly used for transformer cores with unidirectional flux.

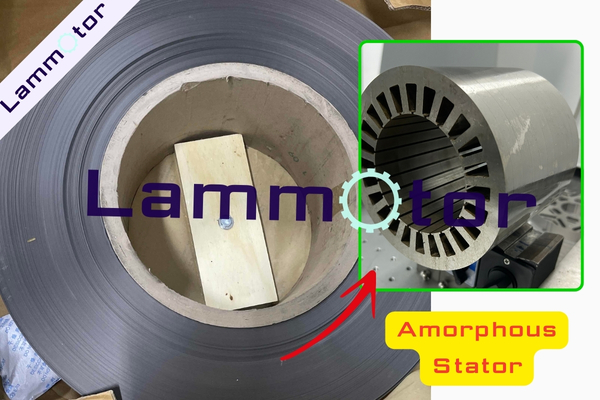

Amorphous alloys

Amorphous alloys offer extremely low core loss due to ultra-thin thickness.

Typical iron-based amorphous alloys use Fe–Si–B composition and are supplied as ultra-thin strips of about 0.02–0.03 mm.

Their main advantage is extremely low core loss. With thickness one order of magnitude lower than silicon steel and resistivity about three times higher, both eddy current loss and hysteresis loss are greatly reduced.

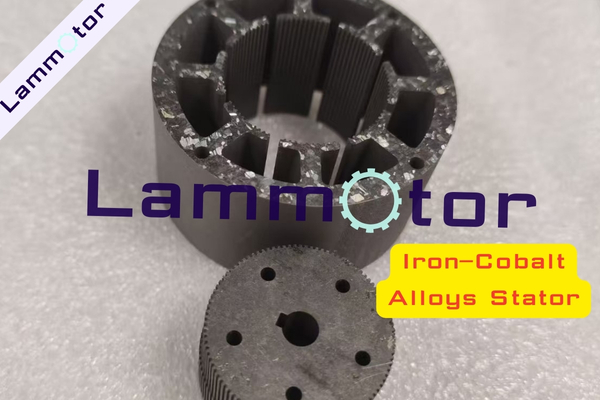

Iron–Cobalt Alloys

Iron–cobalt alloys contain a high proportion of cobalt and are known for their very high saturation magnetic flux density.

At room temperature, a 35% Co – 65% Fe alloy can reach over 2.0 T, the highest among soft magnetic materials.

This allows higher flux operation, significantly increasing motor torque and power density, especially for compact high-performance motors.

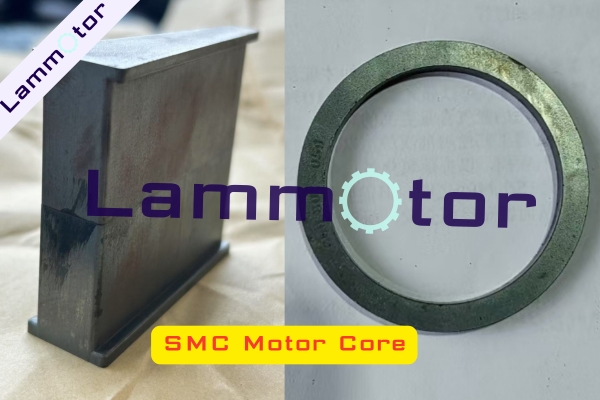

Soft Magnetic Composites (SMC)

SMC materials are made by compacting insulated pure iron powder particles.

At frequencies above 1 kHz, SMC cores show much lower eddy current loss than laminated silicon steel.

YASA’s axial flux motors use a yokeless segmented stator structure, widely considered similar to SMC or separated-tooth technology. It achieves very high torque density and adoption in supercars such as Ferrari.

Nanocrystalline Alloys

Nanocrystalline alloys are obtained by heat-treating amorphous materials to form nanometer-scale grains.

They offer higher permeability and lower loss than conventional amorphous alloys. Typical iron-based nanocrystalline materials have a saturation flux density of 1.2–1.5 T, slightly lower than high-grade silicon steel at around 1.8 T.

Contact Us For Manufacturing Motor Stator and Rotor Core

If you are working with ferro-nickel 1J50 material and need reliable support for 1J50 lamination cores, motor stator and rotor cores, or custom soft magnetic core manufacturing, we can help.

We support cutting, stacking, stress-controlled assembly, and vacuum annealing based on real production experience.

Contact us to discuss your motor core design, material selection, and manufacturing requirements.