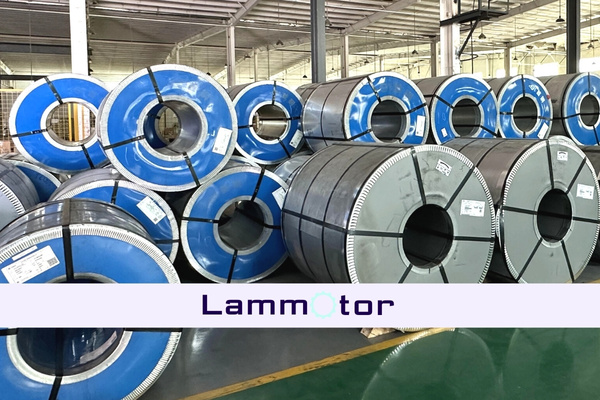

Custom Electrical Steel Laminations Manufacturer in China

Electrical steel laminations are thin layers of specialized electrical steel that are used to construct the cores of transformers, electric motors, and generators. They are produced by a rapid stamping process. Usually, we produce silicon steel laminations thicknesses between 0.25 and 1 mm. We produce rotor and stator laminations and assembled stator and rotor lamination stacks.

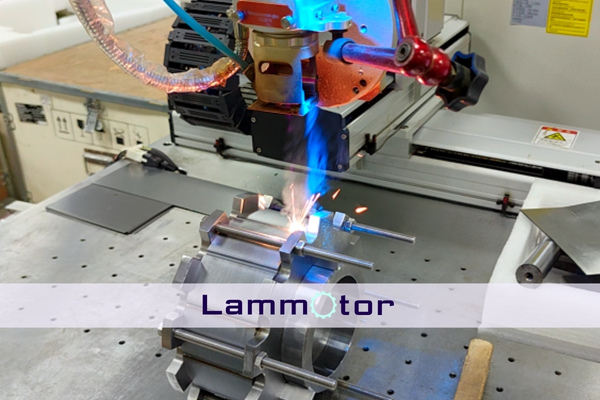

Prototyping motor laminations

We have the expertise and equipment needed to produce high-quality prototype laminations. We offer two primary methods: laser cutting and wire EDM.

Laser cutting is a precise and efficient method that uses a high-powered laser beam to cut the steel sheets into the desired shape. This method produces clean edges and can be suitable for various types of laminations. However, it may not be suitable for thicker materials or complex shapes.

On the other hand, wire EDM involves using a thin wire to cut through the steel sheets, creating complex shapes with high precision. This method is ideal for thicker materials and intricate designs. Our EDM cutting capability is up to 1-micron tolerance.

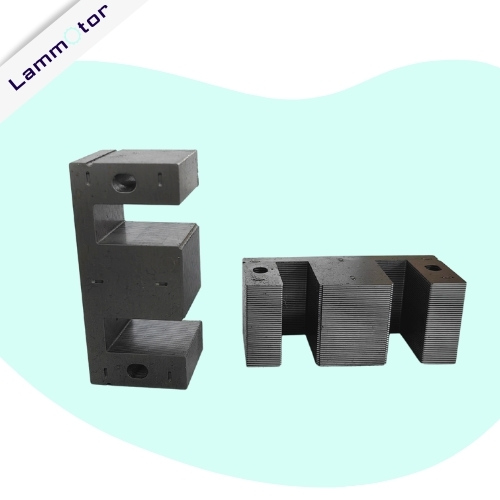

Silicon Steel Laminations assemble

For assembling silicon steel laminations, we offer a range of stacking options to suit different requirements. And we ensure that our silicon steel laminations are assembled to the highest standards of quality and efficiency.

Interlocking is a popular method that involves placing individual laminations on top of each other in a specific order to create a stack.

Bonding is another option, where an adhesive material is suitable for bonding the laminations together. This method can provide additional stability and reduce vibration in the final product.

Finally, welding is a more permanent method that involves fusing the laminations together using heat or pressure. This method is ideal for applications that require high strength and durability.

Customize product range of electric steel laminations

As a manufacturer of electric steel laminations, we understand the need for customized products to meet our customers’ specific requirements. Here are some of the product ranges that we offer:

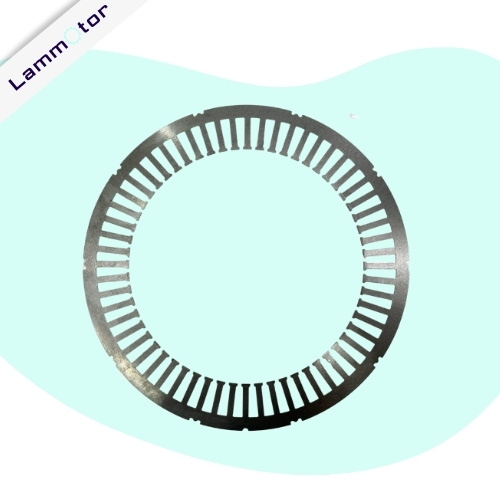

stator laminations

We produce stator laminations that are designed specifically for electric motors, generators, and other electrical equipment. Our stator laminations are available in various shapes and sizes, allowing us to cater to the specific needs of our clients.

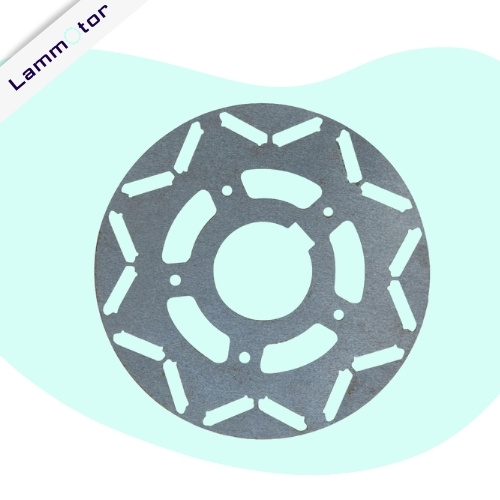

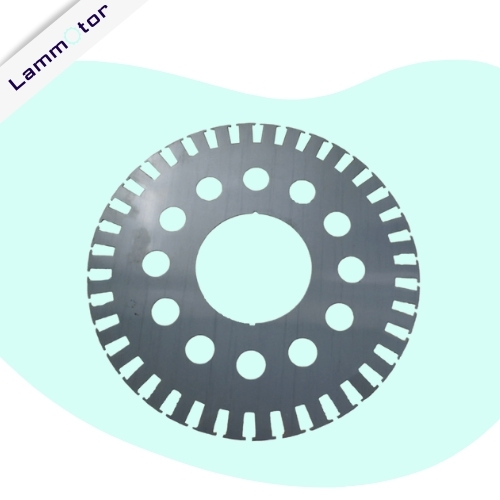

rotor laminations

Our rotor laminations are used extensively in electric motors and generators, where they play a crucial role in converting electrical energy into mechanical energy. We can customize rotor laminations to fit the specific needs of our clients.

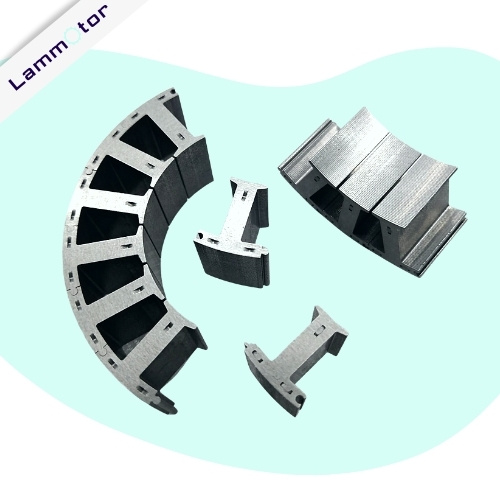

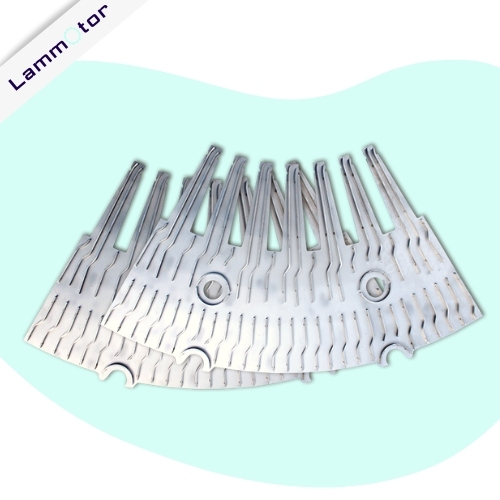

Segmented laminations

These are specialized laminations that are used in high-speed motors and generators. T-segment laminations are suitable for maximizing raw material utilization and winding density. We can design segmented laminations based on our customer’s specific requirements.

Transformer laminations

Transformers are an essential part of the electrical grid and industrial applications. We manufacture transformer laminations according to client specifications, ensuring the optimal performance of the transformer.

Armature Laminations

Armature laminations are used in the production of electric motors or generators. They are made from thin layers of electrical steel stacked on top of each other. We can customize armature laminations based on our customer’s specific requirements.

Vent Laminations

Vent laminations are used in electric motors and generators to allow for proper ventilation and cooling of the equipment. We can produce highly customized vent laminations to match our customer’s unique specifications.

motor lamination steel grades

There are two main grades of electrical steel: grain-oriented (GO) and non-oriented (NO).

Non-oriented Electrical Steel

Non-oriented electrical steel has a random crystal orientation and is better suitable for smaller electrical components like motors and generators.

Grain-Oriented Electrical Steel

Grain-oriented electric steel has a highly directional crystalline structure that allows it to exhibit superior magnetic properties in the direction of its grain. This makes it ideal for use in large power transformers.

Comprehensive Testing Services

quality control for Electrical laminations

To ensure the quality of stator laminations, it is important to implement several measures throughout the manufacturing process.

We use CMM to accurately measure the dimensions of the laminations and verify their conformity to the design requirements.

We provide inspection reports at various stages of the manufacturing process.

Various tests on the finished laminations, such as core loss testing and magnetic flux density testing.

OUR SERVICES

Why Choose Us as Your Electric Steel Laminations China Manufacturer?

With our commitment to quality and customer satisfaction, we are confident that we can provide you with the best electrical steel laminations in China. There are several reasons why you should choose us as your electrical steel laminations China Manufacturer.

Thin Gauge

Additionally, we can produce 0.10mm gauge electrical steel capability. Motor laminations thickness from 0.10 mm to 1mm.

Stamping Capabilities

Our stamping capabilities enable us to produce large quantities of laminations quickly and efficiently.

Laminations Design

We have highly skilled engineers who specialize in designing laminations that meet the exact specifications of our clients.

Other motor laminations materials

In addition to lamination steel, nickel alloy, and cobalt alloy are also suitable for motor laminations. These materials have higher magnetic permeability and lower core losses compared to silicon steel.

Nickel alloys, like permalloy, are commonly suitable in high-frequency applications, while cobalt alloys, like vanadium-fermenter, are suitable in high-temperature applications.

However, these materials are more expensive and harder to work with than silicon steel, making them less common in mass-produced motors. Nevertheless, they are a good choice for specialized applications where high efficiency and performance are critical.

electrical Steel Laminations FAQs

Electrical steel laminations are typically very thin, with a thickness ranging from 0.18mm to 0.5mm. This thinness is necessary to minimize eddy current losses and increase the magnetic permeability of the steel.

The laminations are typically made by stacking multiple layers of thin electrical steel sheets and then punching holes through them to create the required shape for the electrical component.

The thickness of the laminations may vary depending on the specific application, but in general, they are as thin as possible while still maintaining the required electrical and magnetic properties.

Cold rolled motor laminations steel are widely suitable in various industrial applications, including HEV and EV drives, new energy vehicles, aerospace, and defense applications.

In HEV and EV drives, electrical steel laminations are suitable for making the stator and rotor cores of electric motors due to their high magnetic permeability, low core loss, and low eddy current losses.

For industrial applications, they are suitable for transformers, generators, and other electrical equipment.

In the aerospace and defense industries, electrical steel laminations are suitable in motors, generators, and power conversion systems due to their high efficiency, low weight, and compact size.

Therefore, it is clear that electrical steel laminations have a wide range of applications in various industries, making them an essential component in modern-day technology.

Silicon steel laminations contain between 2% and 4% silicon.

The manufacturing process involves multiple steps, including stamping, annealing, and coating.

During the stamping process, the electrical steel is cut into precise shapes and sizes that will fit together to form the completed core.

Annealing involves heating the steel to high temperatures and then cooling it slowly to improve its magnetic properties.

Finally, the coating prevents corrosion and improves the efficiency of the core.

Electrical steel sheets are an integral part of every motor. These laminations are crucial components of these electrical devices as they reduce energy loss during the process of converting electrical energy from one form to another.

Magnetic properties: Silicon steel laminations exhibit excellent magnetic properties, making them ideal for use in electrical equipment such as transformers and generators.

Electrical conductivity: These laminations have high electrical conductivity, which means that they are efficient at conducting electricity and transmitting electrical current without generating excessive heat.

Hysteresis loss: Silicon steel laminations have a low resistance to hysteresis loss, meaning that they do not lose much energy during the conversion of electrical energy.

Energy efficiency: Due to their properties, silicon steel laminations result in reduced energy loss during the conversion of electrical energy, making them an efficient choice for electrical applications.

Corrosion resistance: The application of coatings makes these laminations resistant to corrosion, ensuring a long lifespan for the equipment.

Get High-Quality Silicon Steel Laminations For Your Projects

Are you in need of high-quality silicon steel laminations for your electrical projects? Look no further! Contact us today and we’ll provide you with the best possible solution to meet your specific requirements.

Our high-speed tooling offers a low-cost alternative to manufacturers with moderate to high volume stamping requirements. Our team of experts is committed to delivering top-notch products that will ensure your projects are a success.

Don’t settle for subpar materials, trust us to provide you with the best. Get in touch now and let’s get started!