Have you ever wondered what makes drones zoom through the skies with such precision and agility? It’s all in the motors, my friends. This post is your golden ticket to understanding the types of DC motors for drones and UAVs.

From the hummingbird-like maneuvers of tiny quadcopters to the steadfast hover of industrial UAVs, we’re diving deep into the heart of these machines.

By the end of this read, you’ll not only grasp the essentials of DC motors but also gain insights to make informed decisions for your aerial projects. Let’s propel your knowledge to new heights!

How Do DC motors Function to Power Drones?

At the core of every drone’s aerial prowess lies the heart of its operation: the DC motor cores. These marvels of engineering convert electrical energy into mechanical power, giving our flying friends the thrust they need to conquer the skies.

Imagine the DC t-motor as the diligent worker that keeps the propellers spinning, each turn pushing the drone against gravity’s clutches. The magic lies in the motor’s ability to efficiently manage this conversion process, ensuring that every joule of electricity is optimally utilized for maximum lift and maneuverability.

By understanding this fundamental principle, we unlock the first secret to the drone’s flight—a captivating blend of power and precision.

Types of DC Motors for Drones and UAVs

Drones soar through the skies powered by different types of DC motors for drones, each with its unique characteristics and applications.

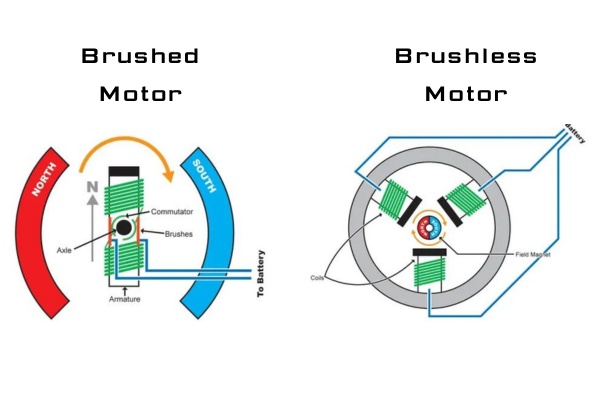

Brushed Motors

Brushed motors, the old-timers of the group. These motors are known for their simplicity and cost-effectiveness. They contain brushes that facilitate electrical connections as the motor spins.

However, like the aging rock stars of the motor world, they come with their wear and tear due to friction between the brushes and the commutator.

Brushless Motors

Then there are the brushless motors, the rock stars of drone technology. These BLDC motors ditch the physical brushes for electronic controllers, reducing friction, increasing efficiency, and extending lifespan. Their precision and power make them the go-to for high-performance drones. They’re like the finely tuned guitars that deliver flawless sound in every performance.

Brushless vs Brushed Motors

When it comes to powering drones, the debate between brushless and brushed motors is akin to choosing between an electric car and a classic gas guzzler. Here’s a breakdown to help you navigate the choice:

Brushless Motors:

Efficiency: Without physical brushes, they operate cooler and more efficiently, translating into longer flight times.

Maintenance: They boast a longer lifespan with minimal maintenance, thanks to the absence of brush wear.

Performance: Offering higher speed, torque, and precision, brushless motors are the choice for performance enthusiasts.

Brushed Motors:

Cost: More wallet-friendly, brushed motors are a cost-effective solution for budget-conscious enthusiasts.

Simplicity: Their straightforward design makes them easier to understand and repair, ideal for beginners.

Durability: While they wear out faster due to brush friction, their simplicity can make them surprisingly resilient in less demanding applications.

In essence, if performance and efficiency are your top priorities, brushless motors are your best bet. On the other hand, for DIY hobbyists and those on a budget, brushed motors might just be the perfect starting point.

Permanent Magnet DC Motors

Permanent magnet DC motors, use magnets embedded in the rotor to generate a constant magnetic field. This design simplifies the motor structure and enhances efficiency, making them a popular choice for lightweight and compact drones. They’re the harmonious blend in the drone’s symphony, offering a balance of performance and durability.

The Impact of Motor Size and KV Rating on Drone Performance

Diving into the intricacies of motor size and KV rating can significantly demystify drone performance dynamics.

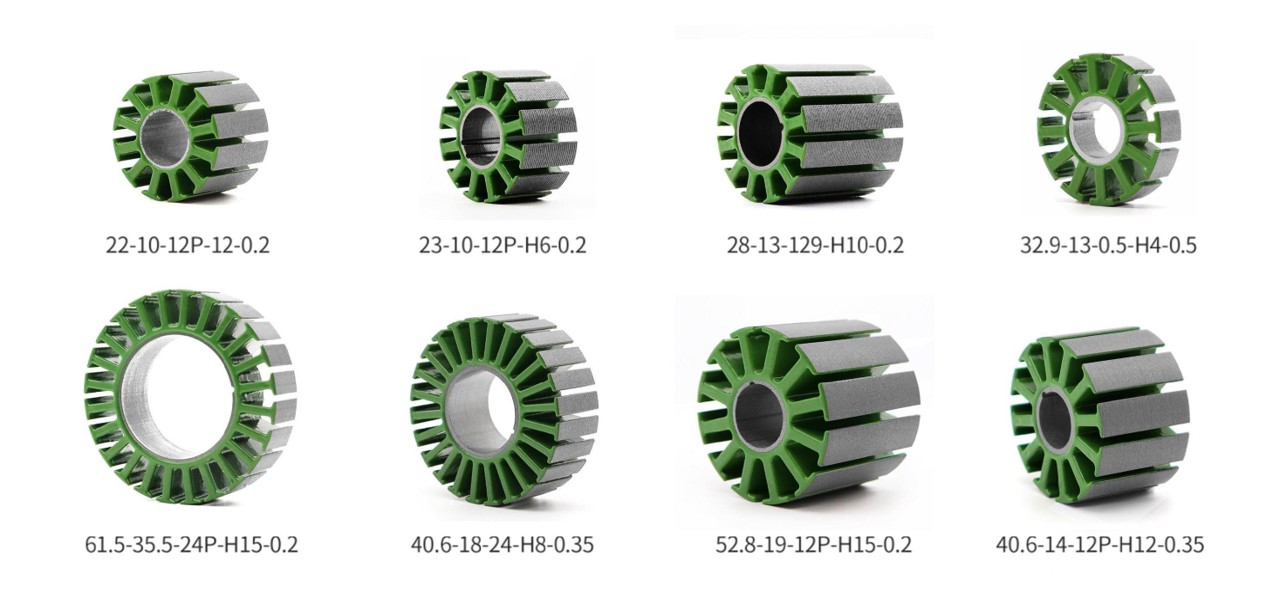

Motor Size: The size of a motor, defined by its diameter and height, directly influences a drone’s lift and maneuverability. Larger motors, characterized by a broader diameter and taller height, generate more thrust, enabling drones to carry heavier payloads. Conversely, smaller motors are suited for lighter drones, prioritizing agility over carrying capacity.

KV Rating: The KV rating of a motor denotes its speed – the number of revolutions per minute (RPM) it will make per volt of electricity supplied. Higher KV motors spin faster, making them ideal for racing drones that require high speeds. Lower KV motors, offering slower rotation speeds, are better suited for larger drones that need more torque to lift heavier loads efficiently. This balance between speed and torque is crucial for optimizing a drone’s performance for its intended use.

The motor size and KV rating are key to tailoring your UAV for its specific tasks, whether it’s high-speed racing or carrying substantial payloads across the sky.

Selecting the Right DC Motor for Your Drone and UAV

There are many drone brands. Choosing the right DC motors for drones or UAVs is like fitting a soul into its mechanical body. It’s crucial, transformative, and a tad mystical. Here’s a little guide to make sure your drone flies high and true:

Weight Matters: Consider the weight of the motor itself. A heavy lift drone motor could weigh down your industrial drone, affecting its agility and battery life. Like choosing the right backpack for a hike, it’s about finding the balance between what you need to carry and what you can carry.

Size Does Count: The size of the motor will influence the overall design and aerodynamics of your drone. Think of it like selecting the perfect shoes for an outfit; they need to fit well and look good, or you might not go far.

Power Requirements: Know the power your drone needs. This is akin to knowing how much fuel your car needs to get to your destination. You don’t want to run out of juice mid-air.

Thrust-to-Weight Ratio: Aim for an electric motor that offers a thrust-to-weight ratio suitable for your drone’s intended use. This is like choosing a car based on whether you’ll be driving in the city or off-roading. Some motors are built for speed, others for carrying loads.

Flight Conditions: Finally, consider where your drone will be flying. Windy, rainy, or challenging conditions require motors that can take a beating and come back for more. It’s like choosing between a city bike and a mountain bike; terrain matters.

Engage with these factors thoughtfully, as if you’re preparing for a grand adventure. Your drone’s performance, efficiency, and the joy it brings you hinge on these choices. Let’s make sure it’s ready to soar into the vast blue yonder, shall we?

Conclusion

From the high-efficiency brushless models to the cost-effective brushed alternatives, each motor type brings its unique advantages to the table. The choice between them hinges on the specific requirements of the drone, such as weight, size, power needs, and the all-important thrust-to-weight ratio, as well as the conditions it will face in mid-flight. Understanding these facets enables you to optimize your drone for either high-speed racing or heavy-lift operations, ensuring a perfect balance between performance and endurance.

If you’re gearing up to either customize your drone or purchase the core laminations for its motor, reach out to us. We’re here to propel your drone or robotics project to new heights with our expertise and high-quality components. Contact us today to explore how we can support your aerial ambitions.

FAQs

Do drones use AC or DC motors?

Drones typically rely on compact small DC motors for their propulsion. This preference for small DC motors stems from their ability to efficiently translate electrical power into mechanical force, essential for lifting and maneuvering the drone through the air.

Which motor is used in DJI drones?

DJI, a leading brand in the drone industry, uses brushless DC motors (BLDC) for their drones. DJI designs and manufactures these motors in-house, optimizing them for each drone model to ensure high efficiency, maximum output power, and quick responsiveness to controls.

Which DC motor is best for drones?

The best DC motor for a drone depends on the drone’s size, weight, and intended use. Brushless DC motors are generally preferred for their efficiency, longevity, and higher power output. They’re especially favored in larger drones and UAVs for their superior performance and minimal maintenance requirements.

How many motors does a UAV need?

The number of motors a drone needs depends on its design. Most quadcopters, as the name suggests, require four motors. The configuration can vary with different drone designs, such as tricopters (three motors), hexacopters (six motors), and octocopters (eight motors), each offering different levels of stability, lifting capacity, and redundancy.