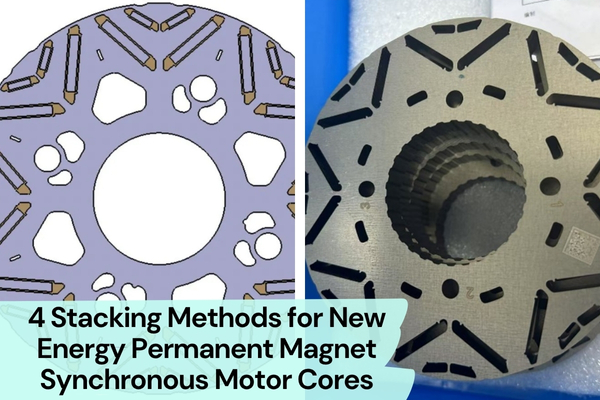

4 Stacking Methods for New Energy Permanent Magnet Synchronous Motor Cores

How does the stacking method of stator and rotor cores affect the performance of a new energy vehicle motor? As a core lamination designer with years of experience, I often encounter this question. In fact, the stacking method directly influences the efficiency, reliability, noise level, and cost of EV motors. Choosing the right method is critical—especially for high-performance permanent magnet synchronous motors (PMSM) used in electric vehicles.