Are you wondering why winding methods are critical in axial flux motor design? As an experienced motor designer, I’ve spent years optimizing winding structures to improve performance, reduce loss, and simplify manufacturing.

In this blog, I’ll guide you through the most common and advanced winding techniques used in axial flux motors. Whether you’re an engineer or just curious about motor technology, this article will help you better understand how different winding strategies impact the performance of axial flux motors.

If you would like to know BLDC motor winding, please click the link.

Winding Methods for Axial Flux Motors with Yoke

1. Concentrated Winding

This method uses traditional round enameled wires, with each phase winding concentrated on one or more teeth. It is widely used in cost-sensitive or space-constrained low-power axial flux motors.

Advantages:

- Simple structure, easy to wind and maintain

- Shorter end turns, when combined with fractional-slot structures

- Common in low to medium voltage EV motors and industrial drives

Disadvantages:

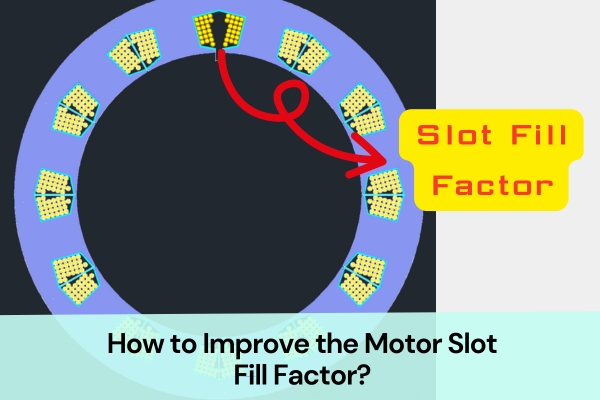

- Lower slot fill factor

- Higher temperature rise

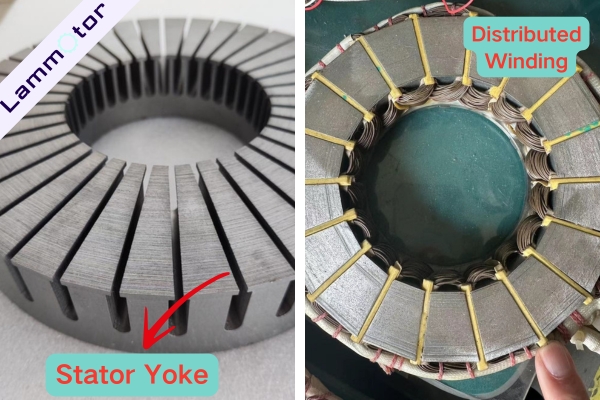

2. Distributed Winding

Here, winding turns are spread over multiple teeth, more like traditional induction motor windings.

Advantages:

- Better electromagnetic performance, fewer harmonics

- Smooth output, suitable for torque ripple-sensitive scenarios

Disadvantages:

- Complex process

- Longer end turns take up more space

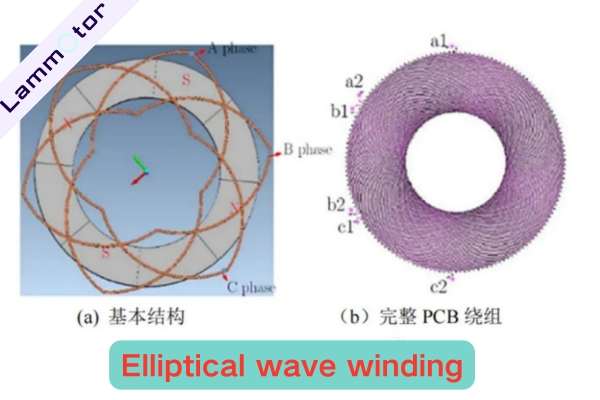

3. Wave Winding

Wave windings allow for more flexible wire routing, beyond the constraints of conventional spiral shapes, enabling innovative designs to enhance motor performance.

However, traditional wave windings often have longer end connections, which increase copper loss.

An alternative elliptical wave winding design, as shown in the diagram, has nearly zero end connections. This greatly reduces end effects and is ideal for high-speed applications.

Winding for Yokeless Axial Flux Motors

1. Flat Wire Concentrated Winding

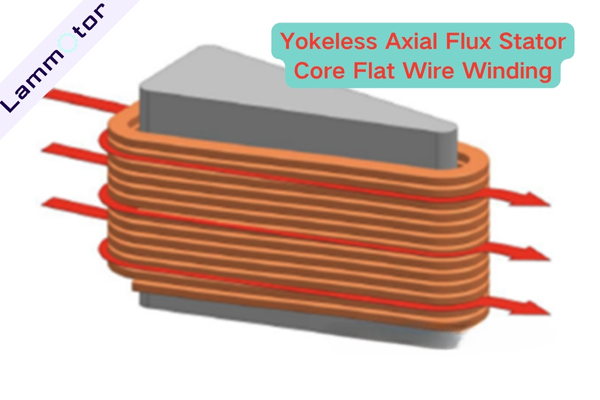

The motor core plays a crucial role in the magnetic circuit, directly affecting the motor’s efficiency. In traditional cores, the yoke completes the magnetic loop but contributes to hysteresis and eddy current losses.

Yokeless core technology optimizes magnetic circuit paths and materials, allowing magnetic flux to pass through the active area more efficiently and bypass the yoke. This reduces magnetic reluctance and lowers hysteresis and eddy current losses by up to 35%.

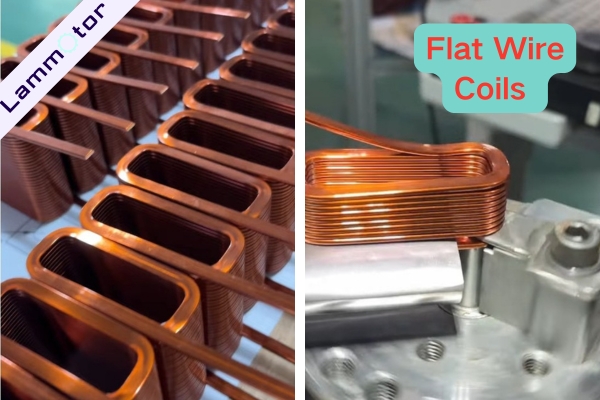

This structure uses flat-wire concentrated windings, eliminating the “hanging” part of the coil. The coils are compact with no wasted space. So, what advantages does this bring?

Let’s look at five key benefits:

- Copper Savings: This winding method can save up to 50% of copper.

- Automation-Friendly: Coil winding and bending are easier to automate.

- Scalable for Mass Production: Offline, parallelized production enables easy scaling.

- Increased D-axis Inductance: Enhances electrical performance → Higher CPSR rating

- Single-Layer Coil Use: Straight conductors form single-layer coils with low internal thermal resistance—ideal for direct oil cooling.

Traxial’s axial flux motors use yokeless stator cores. Each stator has a separately wound flat copper coil, decoupling winding from the assembly and enabling highly efficient automation. The reduction of overhanging copper increases copper utilization by 50%, reducing material weight.

All Traxial windings are laser welded to the busbar, allowing robotic laser welders to automate the process.

Flat Wire Technology: A Slot Fill Game-Changer

In traditional round wire windings, the gaps between wires lower the slot fill factor, limiting current-carrying capacity and electromagnetic performance.

Flat wire winding uses rectangular-section conductors precisely arranged to tightly fit into stator slots. This significantly improves slot fill rate—Voyah’s axial flux motor achieves over 72%.

Furthermore, due to their organized arrangement, flat wire windings provide a smoother heat path, allowing heat to dissipate more efficiently. Their larger surface area enhances immersion oil cooling, further reducing winding temperatures.

How is The Winding of YASA Axial Flux Motors?

Let’s now explore the winding evolution of YASA motors.

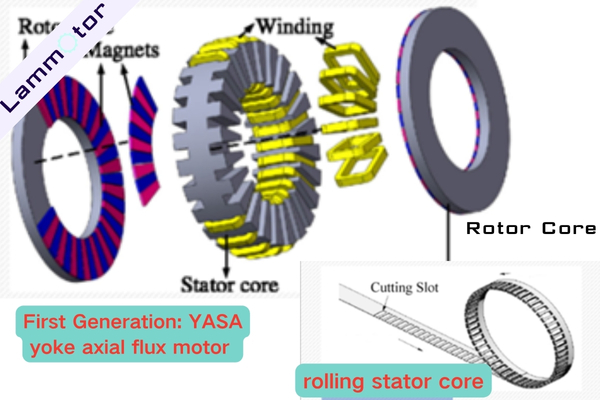

First Generation:

YASA’s initial design featured a traditional R-S-R axial magnetic field structure with a yoke. The stator winding was vertically wound onto the teeth, using laminated silicon steel cores and a “spiral” stacking method.

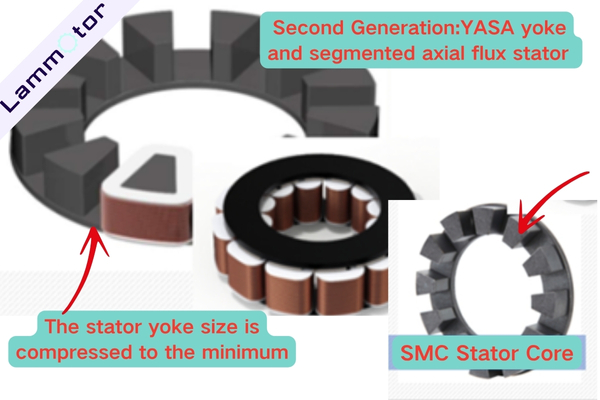

Second Generation:

The yoke was minimal, just enough to connect the teeth. The windings were wound flat onto the teeth. This was enabled by mature SMC (Soft Magnetic Composite) pressing techniques. With isotropic magnetic conductivity, SMC freed the design from traditional lamination constraints, enabling optimal 3D stator geometry and improved space utilization.

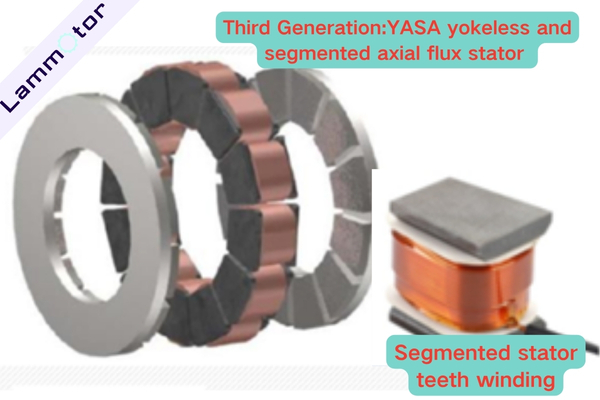

Third Generation – The True “YASA” Structure:

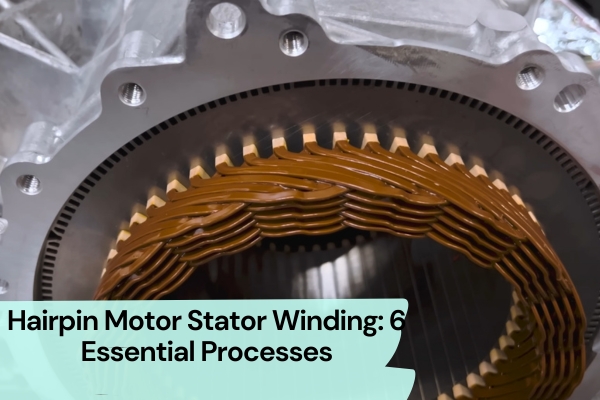

This design eliminated the yoke, maximizing torque density. It uses segmented stator cores, allowing windings to be pre-wound and assembled later—ideal for mass automation. The compact winding design enables very high slot fill factors.

YASA uses multiple extremely flat copper wires wound into flat coils—a result of recent progress in automation technology. These flat windings are pre-formed by automated machines and placed on the stator teeth. Busbars are used to extract the terminals.

The YASA axial flux approach uses less material such as copper, iron and permanent magnet, than conventional e-motors, resulting in a significantly lower material cost and a more environmentally-sustainable product.

Thanks to segmented stator design and flat wire winding, the slot fill factor exceeds 60% net copper, remarkably high for electric motors.

Contact Us For Axial Flux Motor Winding

As we’ve seen, the winding method significantly impacts the performance, efficiency, and manufacturability of axial flux motors. Whether you’re working with traditional yoke-based designs or next-generation yoke-free topologies, the right winding choice can make all the difference.

At our factory, we specialize in the design and production of radial flux motors and axial flux motors, from concentrated round wire windings to high-efficiency flat wire automation. If you’re developing a motor project or looking for a reliable partner to manufacture your custom axial flux motor stator, get in touch with us today. Let’s build the future of electric drive together.