Are you looking for motor technology that could transform the future of electric transportation?

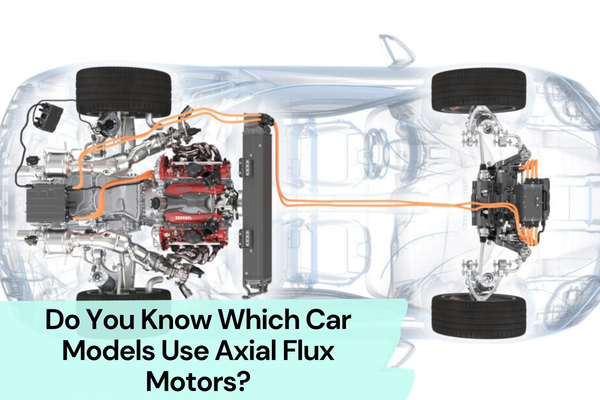

Axial flux motors, with their high power density and compact design, are becoming the preferred choice for electric vehicles, electric aircraft, and industrial applications. More and more companies are pushing the innovation of axial flux motors.

So, who are the leaders in this technology? This article will introduce you to the top 9 axial flux motor manufacturers worldwide. If you want to learn more about axial flux motors, click the link.

YASA

- Founded: 2009

- Founder: Prof. Tim Woolmer

- Website: https://yasa.com

- Main Products: YASA 750 and YASA P400

Since 2009, YASA has been committed to optimizing the production of axial flux motors and expanding their use in transportation. After more than ten years of effort, YASA has established a comprehensive intellectual property portfolio in the field of axial flux motor technology. In China alone, YASA has applied for over 100 axial flux motor patents, ranking among the top in patent filings.

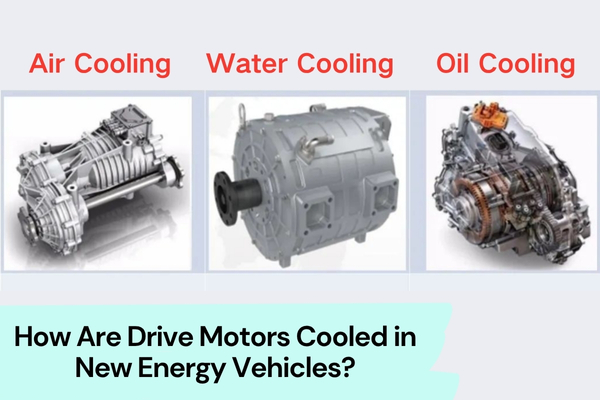

Currently, YASA primarily offers the YASA 750 and YASA P400. These products use advantages like the absence of magnetic yokes, segmented armatures, and direct oil cooling. They demonstrate outstanding performance in traction, generation, hydraulic exchange, and other applications.

Additionally, YASA has developed a new hub axial flux motor, which is already used in Mercedes-Benz’s Vision One-Eleven model. This motor is expected to play a key role in the future AMG.EA electric vehicle market.

Besides electric vehicles, YASA is also involved in motor design for electric aircraft and electric ships.

YASA is also contributing to the architecture design of high-performance ship propulsion systems, such as the EVOA E1 series. With the axial flux motor as the core, YASA plans to launch a 25GTe electric concept ship with partners, aiming to seize the growing market for electric ships.

Shanghai PANGOOD

- Founded: 2016

- Founder: Not disclosed

- Website: https://www.pan-good.com

- Main Axial Flux Motor Products:

- PCB Series: Suitable for light electric vehicles and low-power applications.

- ICS Series: Used in medium-sized electric vehicles and multi-functional applications.

- ICD Series: Used in heavy-duty electric vehicles like buses and trucks.

- 9TFA Series: For specific high-power demands, widely used in construction machinery and large transport equipment.

Shanghai Pangoo Power Technology focuses on providing energy-efficient electric drive solutions and is a leader in the technology field. The company’s axial flux motor is at the core of its solutions, integrated with optimized gearboxes, controllers, and other components to enhance the overall efficiency and performance of electric drive systems.

The company’s electric drive solutions are widely used in new energy vehicles, buses, trucks, electric motorcycles, and engineering machinery.

Pangoo Power’s electric drive systems have significant advantages in power density. Their vehicle drive motors reach a power density of 8.17 kW/kg, surpassing the U.S. Department of Energy’s 2025 standard for motor development.

By early 2023, Pangoo Power had filed 1,178 patents, establishing itself as a global leader in the axial flux motor field.

Magnax

- Founded: 2015

- Founder: Not disclosed

- Website: https://www.magnax.com

Magnax focuses on optimizing the design of magnetless axial flux motors. Since 2015, they have been innovating electric drive technology. The company divides its business into two main departments: Traxy and Axyal, which serve different application areas.

Traxy Axial Flux Motor Series

Traxy focuses on providing efficient magnetless axial flux motor solutions for ground vehicles. The product design emphasizes a balance of power density, efficiency, and reliability, suitable for electric cars, buses, and other vehicles.

Axyal Axial Flux Motor Series

Axyal is focused on aerospace propulsion systems. This series of motors is designed for high efficiency and power density, meeting the strict requirements of aerospace applications regarding power, weight, and size.

Magnax’s Advantages in Axial Flux Motors

Magnax’s magnetless axial flux motors have achieved multiple breakthroughs in manufacturing, including:

Rectangular-section wire: This increases copper fill by up to 90%, enhancing motor efficiency.

Grain-oriented steel: Used in the stator core to reduce core losses to 15% of original levels, slightly improving efficiency.

Multiple cooling solutions: Including air, water-glycol, and oil mixed cooling, and laminated radiators for better heat dissipation.

Representative Product:

AXF225 Axial Flux Motor: This motor weighs just 13 kg and delivers 220 kW peak power. The peak torque and weight are equivalent to the HSM radial motor three times its size (e.g., BMW i3 motor), showcasing the significant advantages of the magnetless design in high power density and light weight.

Shenzhen SEMOTOR

- Founded: 2016

- Founder: Not disclosed

- Website: https://www.semotor.cn

- Main Axial Flux Motor Products:

- SEmotor1K: Used in small quadruped bionic robots.

- SEmotor6K: Used in large bionic robots and joint motor systems.

These motors have the following features:

- Power Density: Reaches 10 kW/kg.

- Torque Density: Reaches 20 Nm/kg.

- Efficiency: No less than 97%.

- Peak Power: From 1.5 kW to 100 kW.

Technical Advantages:

Compared to traditional radial flux motors, Little Elephant’s axial flux motors offer significant advantages in volume, weight, and efficiency. They are especially suitable for applications that require reduced size and weight.

Application Areas:

- New energy vehicles

- Electric motorcycles

- Industrial robots

- Drones

- Electric ships

- Electric aircraft

Shenzhen Little Elephant Electric Technology specializes in the development of high-energy magnetic motor technology and providing drive solutions. The company has leading disc motor production and control technologies in China. Their axial flux motors offer high power density and efficiency, with products being 1/3 to 1/2 the size and weight of traditional motors.

Phi-Power AG

- Founded: Not disclosed

- Founder: Not disclosed

- Website: https://www.phi-power.com

- Axial Flux Motor Series:

- Phi301: Designed for high-power applications.

- Phi271: For medium-power applications, balancing performance.

- Phi27S: Optimized for high-speed applications, providing higher torque.

Technical Advantages:

- High Power and Torque Density: Compared to traditional motors, Phi-Power’s axial flux motors offer more power and torque in the same space.

- Compact Design: Especially suitable for applications with short installation lengths, offering higher power density.

- High Protection Rating: These motors use a sturdy enclosed design with IP6k9 protection for reliability in harsh environments.

- Custom Designs: Phi-Power offers custom designs for specific application needs, such as hybrid machines or range extender generators.

Application Areas:

- Racing

- Heavy trucks

- Hybrid and range-extended electric systems

Evolito LTD

- Founded: Not disclosed

- Founder: Not disclosed

- Website: https://evolito.aero/axial-flux-motors

Evolito focuses on providing advanced axial flux motors for the aerospace industry. These motors are known for their small size and light weight, delivering higher torque and power density, especially in speeds suitable for propulsion.

- D250: Low torque, high speed, suitable for high-speed applications.

- D500: Medium torque, medium speed, suitable for balanced torque and speed applications.

- D1500: High torque, low speed, suitable for applications requiring high torque at low speeds.

Technical Features:

- Smallest Size and Lightest Weight: Evolito’s motors offer leading advantages in size and weight compared to similar products.

- Yokeless Design: The use of yokeless design combined with segmented magnets reduces weight and improves performance.

- Enhanced Safety: Evolito motors use 1×3 and true 2×3 phase shift designs for increased safety.

- Integrated Redundancy and Sensors: These motors include dual-channel redundancy systems with position and temperature sensors, ensuring stability in high-safety environments.

- Custom Windings: Evolito can customize windings to optimize performance based on specific application needs.

Application Areas: Evolito’s axial flux motors are widely used in aerospace applications, including:

- eVTOL (electric vertical takeoff and landing aircraft)

- UAM (urban air mobility)

- Helicopters

- Fixed-wing general aviation aircraft with one or multiple rotors

Evolito is helping the aerospace industry move away from the limitations of traditional radial flux motor technology and accelerate electrification for future electric aviation.

Hangzhou ZONHOW

- Founded: 2017

- Website: https://www.zonhowemt.com

- Products: 45kW, 65kW, and 300kW axial flux permanent magnet generators

Product Features:

This company’s products use dual-stator axial flux motor technology, reducing size by one-third and weight by 30% compared to mainstream products.

The flat structure and low-speed, high-torque performance are perfectly suited for range extender generators.

Once installed, the motor does not extend beyond the engine’s intake system.

The entire range extender system is designed to be compact, easily fitting into tight vehicle spaces, and meeting the lightweight requirements of modern vehicles.

Application Areas: This company’s axial flux motors are used in 1.5T-4.5T city logistics light trucks, heavy mining trucks, and large construction machinery.

The motor’s compact design, low-speed, high-torque performance, and efficient areas make it an ideal match for internal combustion engines. Axial flux motors help to optimize the overall structure and improve fuel efficiency, making the range extender more effective.

BEYOND Motors

- Founded: Unknown

- Founder: Domen Kočevar

- Website: https://www.beyondmotors.io

BEYOND Motors focuses on the design and manufacturing of high-performance axial flux motors, offering exceptional power density, efficiency, and reliability.

Their motors are widely used in maritime, aerospace, trucking, automotive, and industrial fields, providing efficient electric drive solutions to help customers achieve higher energy efficiency and longer range.

Siemens AG

- Founded: 1847

- Founder: Werner von Siemens

- Website: https://www.siemens.com

Siemens, a global leader in electrical engineering, has a strong background in the development and application of axial flux motors. The company uses this technology in various fields, especially in industrial and automotive sectors.

Siemens is dedicated to providing efficient and intelligent electric drive solutions, and its products have significant applications in many industries.

Siemens has made many innovations in the research and development of axial flux motors, particularly in high power density, efficiency, and size/weight optimization. Their axial flux motors are used in electric vehicles, electric motorcycles, and sustainable energy-driven systems in emerging industries.

Contact Us to Manufacture Axial Flux Motor Stator and Rotor

Which axial flux motor manufacturer do you think is the most innovative? Feel free to discuss in the comments section or contact us directly.

We are a leading axial flux motor manufacturer in China with over ten years of industry experience, specializing in providing high-efficiency, reliable motor cores. Our products are widely used in electric vehicles, industrial robots, electric ships, and other fields, and we also support customized solutions.

If you need high-quality axial flux motor stators or rotors, please feel free to contact us at any time.