Wire EDM Cutting Motor Lamination Manufacturer In China

We are a reliable wire EDM cutting for motor core lamination manufacturer in China. And we can manufacture all kinds of motor core lamination stack for industrial applications. We have years of experience in this field and are committed to providing the highest quality products and prototyping services possible.

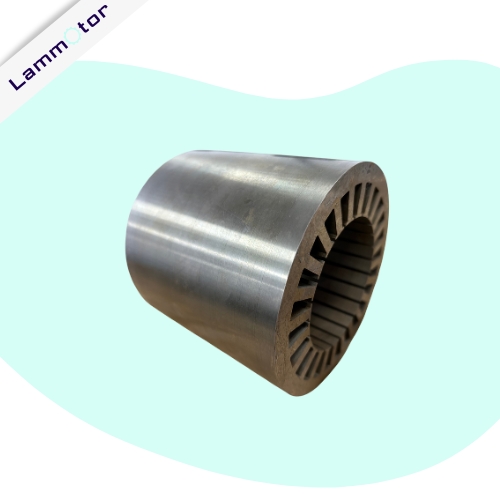

Wire EDM cutting motor laminations

Using wire EDM cutting, we can manufacture complex shapes that can be cut from silicon steel sheets. We have high-precision wire EDM equipment that provides precise, repeatable results for all your machining needs. And it can stack and cut multiple layers of silicon steel at once, which speeds up turnover and reduces production costs.

Meanwhile, we provide EDM slow wire processing to provide more accurate processing. This process utilizes an electrically charged thin wire to cut through metal with incredible accuracy, often reducing production times by up to 70%.

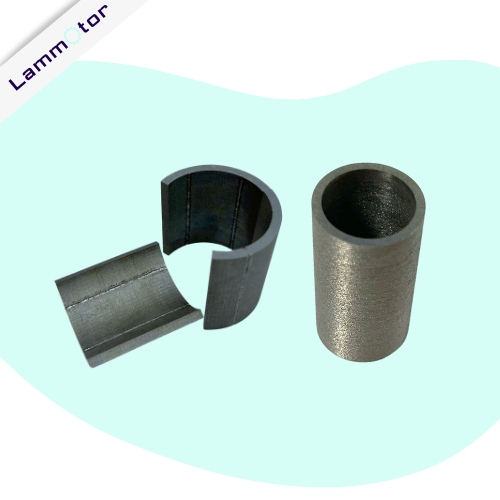

wire EDM prototyping motor laminations

Wire EDM cutting is one of the methods of prototyping motor cores. Through wire cutting, we can reduce the cost of the prototype sample before the stator core production approval. The tolerance and performance are better than the laser cutting motor stator.

OUR SERVICES

why choose us for electric motor lamination stacks?

We can provide custom solutions for any lamination needs. Besides standard motor stator and rotor lamination, we can also produce customized laminations.

Superior Accuracy

We offer superior accuracy and improved productivity compared. And we ensure precision edges and tight tolerances for each lamination.

quality control

We employ a rigorous inspection process to ensure top quality. Our in-house quality team ensures high standards are met. We can accurately produce parts that meet customer specifications.

Quick Turn-Around

Our wire EDM cutting technology allows quick turnaround times and delivery, making it an ideal choice for projects with deadlines. We can provide custom solutions to meet your specific requirements.

wire EDM Motor lamination FAQs

Due to its excellent magnetic properties, silicon steel is the most commonly used material in wire EDM motor laminations.

Silicon steel is formed from iron and silicon alloyed with other materials like molybdenum or aluminum.

Silicon steel has several advantages as a material for motor lamination; it has low losses despite its lack of hardness.

We can easily stamp it into many shapes, and it’s relatively inexpensive compared to alternative materials.

EDM cutting for motor core lamination is one of the most efficient and cost-effective methods to produce high-quality motor cores.

Its advantages include precise and accurate cuts, high production speeds, reduced material wastage, and improved surface finish.

Furthermore, EDM cutting eliminates grinding and tooling time, making it faster than traditional cutting methods.

All in all, EDM cutting prototypes superior quality cores effectively in less time with minimal wastage.

Need to prototype electric motor lamination?

We are a motor core lamination China manufacturer. We can mass produce and prototype motor stator and rotor lamination stacks. Contact us for wire EDM lamination.