Motor Stator Winding in China

We specialize in the stator and rotor assembly of new energy vehicle motors, industrial automation motors, air conditioning compressors, energy storage, fan motors, and related motor products. We provide motor stator coil winding services, including slot insulation, coil insertion, single-layer and double-layer winding, and both round and flat wire winding.

With advanced automated winding machines, we ensure precision, consistency, and cost-efficiency in every stator we deliver. Whether you’re developing a new electric motor, generator, or transformer, we’re here to support your project with expert guidance and manufacturing capabilities.

Stator Coil Winding Services Capability

We offer comprehensive stator coil winding services tailored for both prototyping and mass production. Whether you require a few pieces for testing or large-scale production, we provide flexible solutions to meet your project timeline and budget.

Manual Winding Samples for Prototypes

For low-volume projects or new product development, we offer manual stator winding for samples of fewer than 10 pieces. This allows rapid prototyping and design validation.

Our technicians are skilled in producing precision wound coils by hand, ensuring accuracy and repeatability even at the sample stage.

Automated Winding for High-Volume Orders

When it comes to mass production, our fully automated stator coil winding machines ensure consistency, reduce labor costs, and boost efficiency.

We design custom winding fixtures to stabilize stators during winding, which helps maintain wire alignment and ensures optimal performance in the final motor. This method is ideal for custom stator winding in electric vehicles, HVAC systems, and energy storage drives.

Motor Stator Core Winding Products

We have rich experience in providing stator winding services for various motor types across different industries. Our product portfolio includes BLDC stator core winding, axial flux motor winding, segmented stator coil winding, and linear motor winding.

We also support more specialized applications such as coreless motor winding, EV stator winding, and compressor motor winding. Whether you need precision for micro motors or high-power coils for electric vehicles, we can deliver reliable and customized solutions.

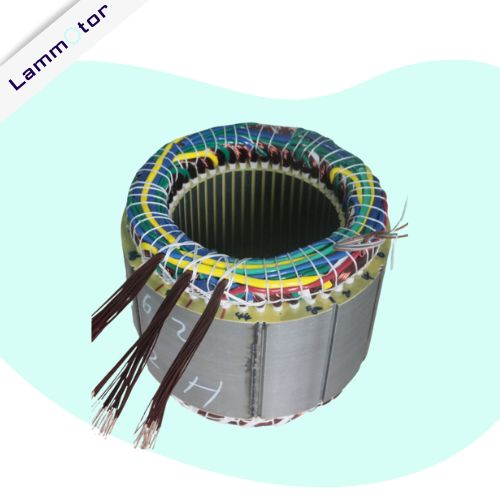

BLDC Motor Winding

Axial flux stator winding

BLDC stator coil winding with bobbin

segmented stator winding

BLDC stator winding

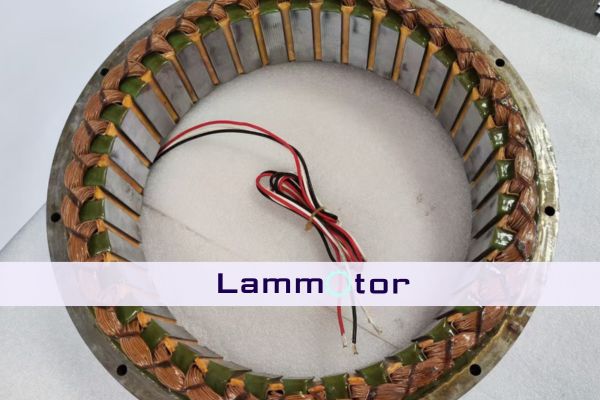

EV stator core winding

air compressor stator winding

linear Motor Winding

Types of Motor Stator Winding We Provide

We offer a variety of stator winding types to meet different motor design requirements. Depending on your application—whether it’s an EV motor, fan motor, or industrial servo—we can provide the most suitable winding structure to optimize performance, efficiency, and manufacturability.

Concentrated Winding

Concentrated winding typically consists of one or several rectangular coil frames wound around a narrow number of slots. After winding, the coils are shaped with tape, varnished, and dried before being inserted into salient pole stator cores.

This type of winding is commonly used for field coils in DC motors, universal motors, and main pole windings in single-phase shaded pole motors.

Distributed Winding

In distributed winding, the stator does not have prominent salient poles. Each magnetic pole is formed by a group of coils evenly spread across multiple stator slots.

Based on the layout of the coils, distributed windings can be categorized into concentric winding and lap winding formats. This structure allows smoother torque and is widely used in three-phase induction motors and synchronous motors.

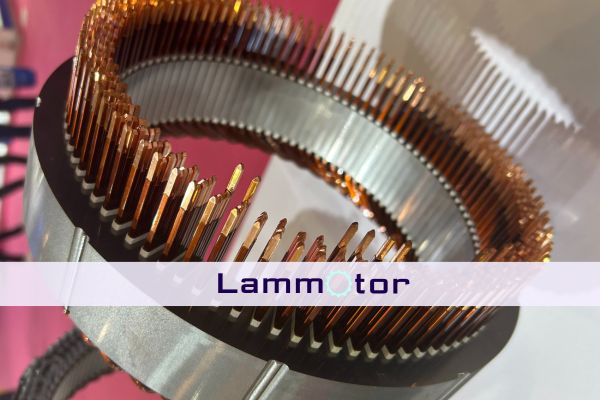

Flat Wire Winding (Hairpin Type)

Flat wire winding, also known as hairpin winding, includes designs such as Hair-Pin, I-Pin, and W-Pin continuous-wave winding. This winding technique uses rectangular-section copper wire, which offers higher slot fill factor, lower resistance, and better thermal management.

It is a popular solution for electric vehicle motors and high-performance BLDC stators where power density and efficiency are critical.

OUR SERVICES

Automated Stator Winding Process

Our automated motor stator winding process ensures precision, consistency, and high insulation reliability. The full process includes:

- Slot Insulation Insertion – Insert high-temperature insulation paper to protect copper wire from short circuits.

- Layer Coil Winding – Wind the coil layer with round or flat copper wire using automated machines.

- Lead Wire Insertion (UVW) – Add UVW lead wires for electrical connection.

- Spot Welding – Secure wire ends for electrical continuity.

- Forming and Shaping – Shape the coils to improve slot fill and motor balance.

- Lacing or Tying – Fix coils in place using heat-resistant thread.

- Vacuum Impregnation (VPI) – Deep resin penetration to enhance insulation and mechanical strength.

- Baking and Curing – Harden the insulation and secure coil position.

- Winding Quality Tests–Every stator is tested with: Saline water test, Resistance test, Turns count verification, High-voltage test, Insulation resistance test

OUR SERVICES

Winding Specifications and Materials

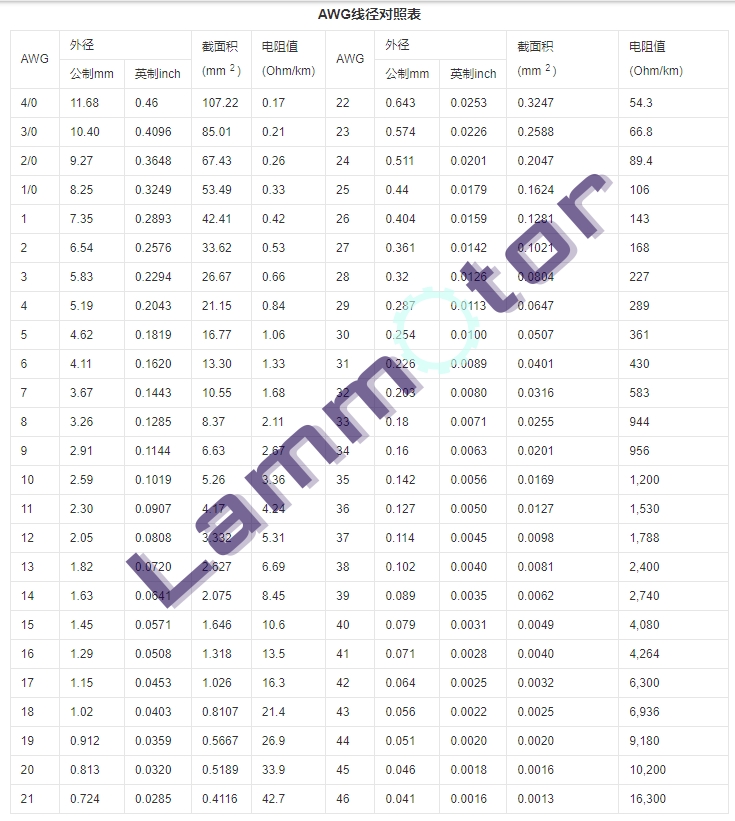

We offer enameled copper wire and lead wires that meet both IEC 60317 and AWG standards. All wires are available in Grade 2 enamel, suitable for high-speed and high-temperature motor applications.

Our insulation systems support Class F (155°C) and Class H (180°C) materials, ensuring safe performance under demanding thermal conditions.

For radial flux motors using round wire, our optimized winding process achieves up to 75% slot fill factor, improving efficiency and power density.

Industries and Applications We Serve

Our stator winding services are widely used across multiple industries. From electric vehicles to household appliances and factory automation, we support a broad range of motor applications with reliable and high-performance winding solutions.

Automotive and Electric Vehicle Motors—Custom stator coil winding service for EV motors and traction motors used in electric cars, e-scooters, and hybrid drive systems. Our high slot-fill stator coils are designed for high torque, efficiency, and thermal durability.

Home Appliances and HVAC Motors—Supply winding solutions for fan motors, compressor stators, and other HVAC components.

Industrial and Automation Equipment— We manufacture stators for servo motors and BLDC motor stators for automation in robotics, CNC machines, and factory automation systems.

FAQs

We offer concentrated winding, distributed winding, and flat wire winding (e.g. hairpin). The winding type depends on your motor’s design, application, and performance goals.

We can wind stators with an outer diameter from 5 mm to 450 mm, thickness from 5 mm to 300 mm, and 3 to 54 slots.

We use Class F (155°C) and Class H (180°C) insulation systems for better thermal performance and long service life.

Yes. We provide manual stator winding for prototype samples and automated winding for batch production. Custom specs like wire gauge, slot count, and coil turns are supported.

Yes. Each stator undergoes a full test process, including saline water test, resistance test, turns verification, high-voltage test, and insulation resistance test.

Rotor winding includes two types: squirrel cage type and wire wound type. The squirrel cage type has a simpler structure. Its winding used to be copper-embedded belts, but now it is mostly cast aluminum. The special double-cage rotor has two sets of squirrel cage belts.

Get a Custom Stator Coil Winding Quote Today

Whether you’re developing a new motor or optimizing an existing design, we’re here to support you with precision motor stator winding services, fast turnaround, and full customization. With years of experience in motor lamination and coil winding, we offer one-stop solutions for your electric motor projects.

Contact us now to discuss your requirements or request a quote.