Motor overheating and low efficiency—what’s the real problem? The answer is core loss.

If you work in motor design or deal with motors regularly, you may have noticed that sometimes, even when the winding and control system are perfectly fine, the motor still gets hot and its efficiency doesn’t improve. The problem often lies in one critical area—excessive core loss in the stator.

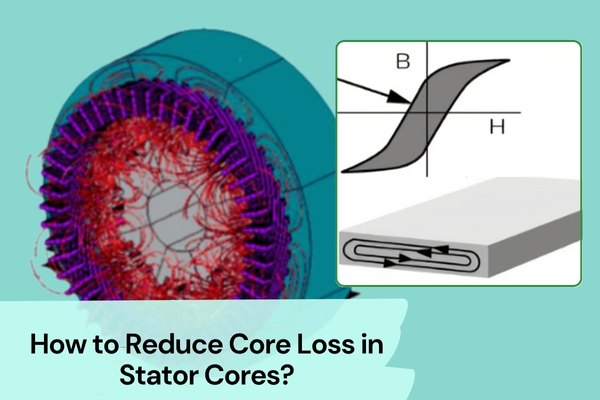

Over the years I’ve been designing motor cores, core loss has been one of the most common challenges. It’s also one of the key factors affecting motor performance. Core loss mainly consists of hysteresis loss and eddy current loss. Even though it’s not always highlighted in technical specs, core loss silently eats away at energy that should have been converted into power.

So how do we reduce core loss? The answer lies in two areas—materials and processing. Based on my experience, I’ll walk you through how to lower stator core loss through better material selection and improved manufacturing processes, helping you truly boost motor efficiency.

1. Materials

Most traditional stator cores use non-oriented electrical steel.

This is a silicon-iron soft magnetic alloy with a silicon content of 0.5–6.5% and extremely low carbon content. It’s typically made by stacking multiple layers of silicon steel sheets.

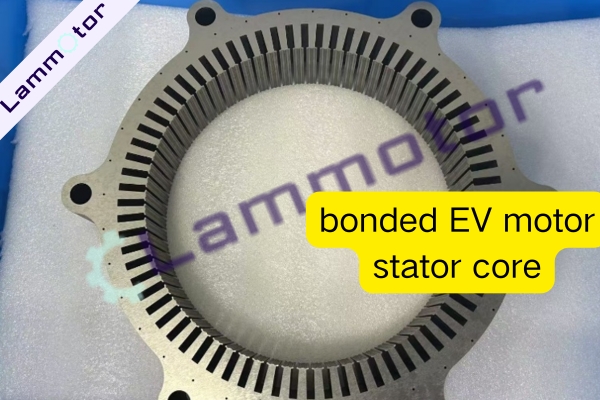

Once stacked, the layers are joined together using bonding, welding, or interlocking to form a solid and continuous structure.

There are two main directions for improving materials—either continue to make existing materials thinner or find entirely new materials.

Use Ultra-Thin Silicon Steel Sheets

Hysteresis loss comes from energy loss during magnetization cycles and depends on the material’s composition and grain size. It’s reflected by the area of the hysteresis loop.

Eddy current loss happens when alternating magnetic fields induce currents inside the core material, causing resistive heating. This loss is related to the material’s resistivity and thickness.

To reduce these losses, we use thinner electrical steel sheets with higher resistivity.

Ultra-thin silicon steel helps limit eddy currents by dividing the current path into smaller loops, increasing resistance and reducing overall current intensity. That’s why motor cores aren’t made from solid blocks of magnetic material but from stacked sheets coated with insulation.

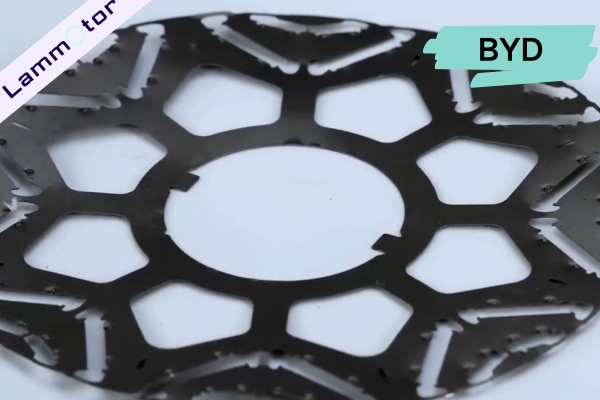

For example, in new energy vehicle motors, thinner sheets (0.2–0.25mm) are used to make the stator more compact and efficient. BYD and Huawei vehicles use 0.2mm and 0.25mm non-oriented silicon steel sheets in their stator cores.

Thin-gauge non-oriented silicon steel usually refers to 0.25mm, 0.20mm, or 0.15mm thickness. Their performance is typically evaluated by total loss under 400Hz at 1.0T and magnetic polarization strength at 5000A/m.

Use Amorphous Materials

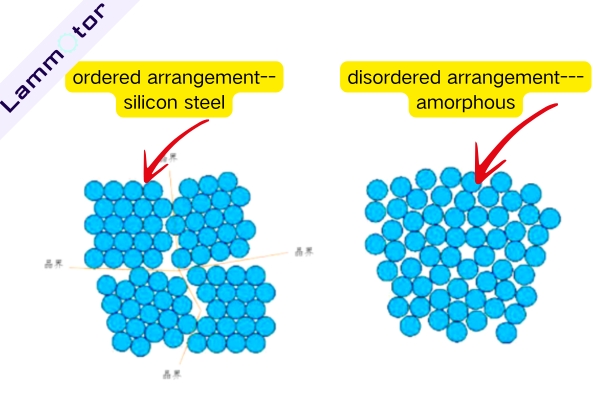

Amorphous alloys are gaining attention. They’re made by rapidly cooling molten metal before its atoms have time to form crystals. This results in a solid with a disordered atomic structure.

The lack of crystal boundaries means amorphous alloys have very low coercivity and significantly reduce eddy current losses. In contrast, traditional materials like silicon steel have grain boundaries where eddy currents are more likely to form.

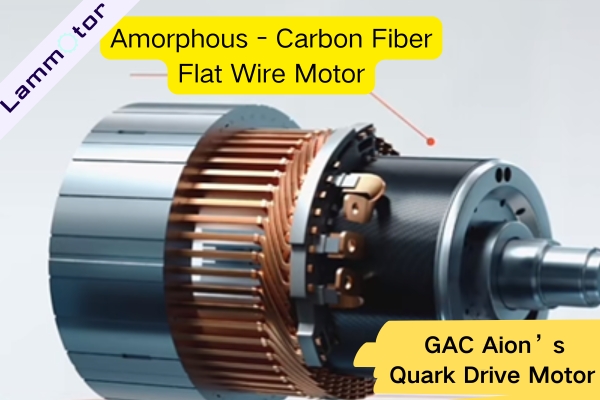

Iron-based amorphous alloys are commonly used in motors. For instance, the stator in GAC Aion’s mass-produced Quark drive (launched in August) uses amorphous material and reportedly achieves 98.5% efficiency with a power density of 13kW/kg.

Its stator core is 90% thinner and has over 50% lower core loss compared to conventional silicon steel.

Amorphous materials can be processed via stamping or wire cutting. We’ve introduced these methods in another article—feel free to read it here: Amorphous Motor Core Process: Three Methods You Need to Know.

2. Manufacturing: From Welding to Bonding

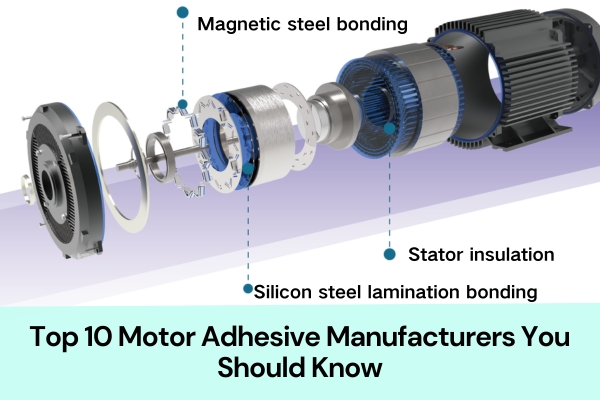

When it comes to stacking the core laminations, current stacking methods include interlocking (slotting), welding, bonding, and backlack (self-bonding). Among these, welding and bonding are widely used today, and backlack is expected to become mainstream in the future.

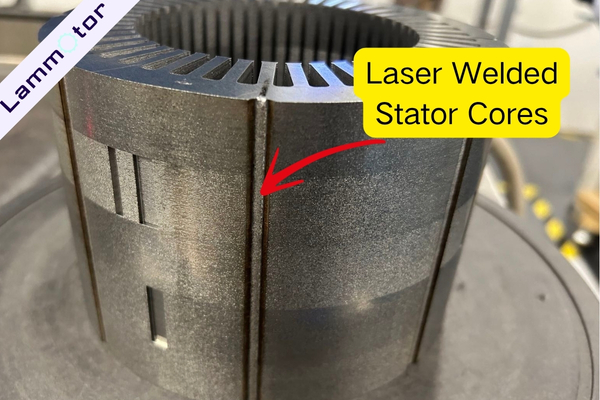

The most commonly used process today is interlocking plus welding. Grooves are machined into the outer surface of the stator core and then fused together using heat.

TIG (Tungsten Inert Gas) and laser welding are the two main options. While TIG was more common in the past, laser welding is becoming popular due to its narrower welds and smaller heat-affected zones. Still, welding can cause interlayer short circuits and thermal damage that negatively affect electromagnetic performance. The wider the weld, the greater the impact.

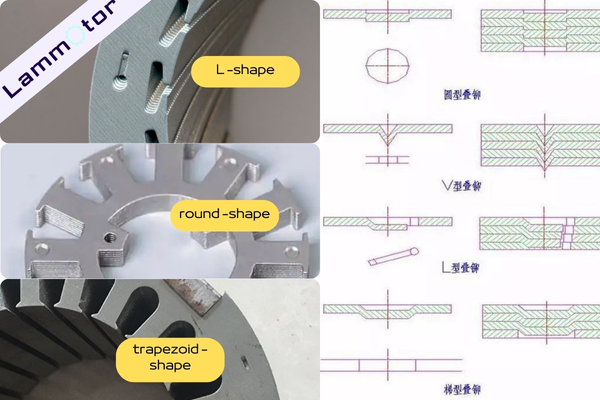

Interlocking involves punching locking tabs into the steel sheets. These tabs generate friction between layers, holding them tightly together.

There are four common locking tab shapes. The most widely used is the rectangular trapezoidal tab, known for its strong bond, good stability, and ability to reduce vibration and noise. However, interlocking is still a localized connection and can interfere with magnetic circuit design.

Backlack (Self-Bonding) Technology

Backlack/Self-bonding electrical steel is coated by the steel manufacturer with a heat-activated adhesive. After drying, this coating remains “active.” When the motor manufacturer stacks and heats the sheets, they bond firmly to form a unified core.

This technique fills the gaps between laminations, improving heat conduction and cooling performance during motor operation.

It also reduces hysteresis and eddy current losses, further improving efficiency.

The coating is typically applied using a reverse-roller method. After coating, it’s baked at 130°C–260°C for 30–45 seconds. During core assembly, the laminations are cured at 130°C–220°C under 6–10 bar pressure for 0.4–4 hours.

The coating must be thin yet offer strong peel resistance to meet the demands of high-speed, high-strength motors in the EV industry.

Imported adhesives such as EB548 and EB549Rapid can withstand long-term temperatures of around 150°C. Baosteel’s locally developed EA3902 can handle up to 180°C.

Contact Lammotor For Backlack/Bonding Motor Stator Core

Reducing stator core loss isn’t just about tweaking one component—it requires choosing the right materials and adopting the right joining process. Whether it’s using ultra-thin silicon steel, switching to amorphous materials, or applying bonding and backlack techniques, each improvement brings you closer to a more efficient, cooler-running motor.

If you’re looking to manufacture bonded or backlack motor stator and rotor cores, we’re here to help.

Contact Lammotor today to get started on your custom solution.