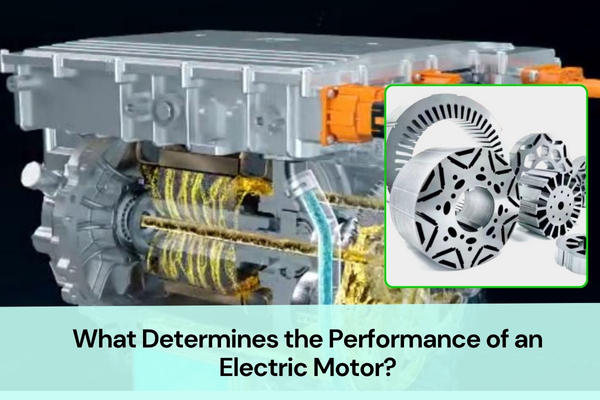

When people talk about electric vehicles, they often focus on power, acceleration, and energy efficiency.

Some believe that as long as you choose the right type of motor—such as a permanent magnet synchronous motor (PMSM) or an induction motor—the performance will naturally be excellent.

But in reality, it’s not that simple.

The true performance limit of an electric motor is not decided by its type or power rating — it’s determined by one critical factor: electric motor cooling.

The acceleration, top speed, and even energy efficiency of an EV all depend on how well the motor can control heat. Cooling not only determines how fast a motor can run, but also how long it can maintain its performance. Every degree of temperature matters.

The Real Core of Motor Performance: The Cooling System

An electric motor generates heat whenever current passes through the windings and the magnetic field changes.

If that heat is not removed quickly, the temperature rises, directly affecting the magnetic materials, insulation, and overall reliability.

For example, a permanent magnet synchronous motor uses rare-earth magnets in the rotor. These magnets are very sensitive to temperature. Once overheated, they can lose magnetism permanently — a process known as irreversible demagnetization.

In an induction motor, the rotor uses copper windings. Under heavy load, these coils release large amounts of heat. Excessive temperature can melt the insulation and, in extreme cases, even damage the windings themselves.

To prevent overheating, most automakers set limits on maximum speed and current output.

This “protective restriction” keeps the motor safe but also locks away part of its potential.

Only when electric motor cooling is significantly improved can the motor truly unleash its power and find the perfect balance between acceleration, speed, and energy efficiency.

Three Key Directions for Efficient Electric Motor Cooling

As electric motors become more powerful and compact, efficient heat management has become the main battlefield for automakers and motor manufacturers.

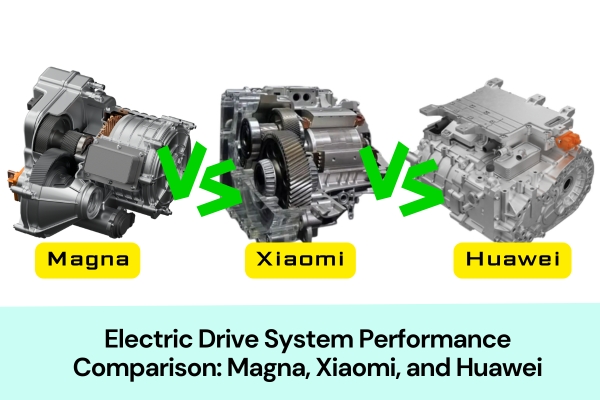

Today, leading companies like Tesla, BYD, and Huawei are focusing on three major innovations: flat wire winding, laminated rotor design, and oil cooling systems.

Let’s explore how each one enhances electric motor cooling performance.

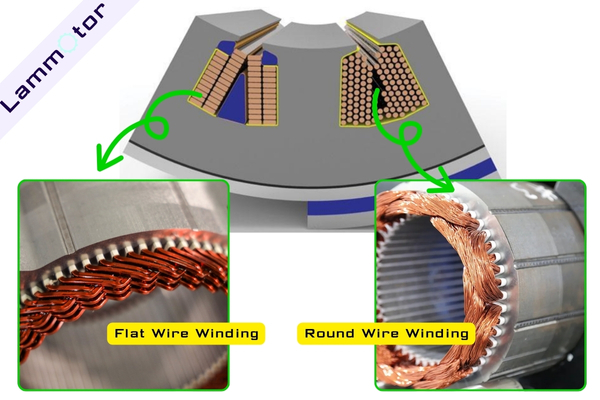

1. Flat Wire Winding – Higher Fill Rate, Better Heat Dissipation

Traditional stators use round copper wires. These leave gaps in the stator slots, which reduces copper density and makes it harder for heat to escape.

Flat wire motors use rectangular copper strips that fit tightly inside the slots, increasing the copper fill rate and improving both efficiency and cooling.

Tests show that flat wire windings can boost efficiency by about 10% and reduce heat generation by another 10%.

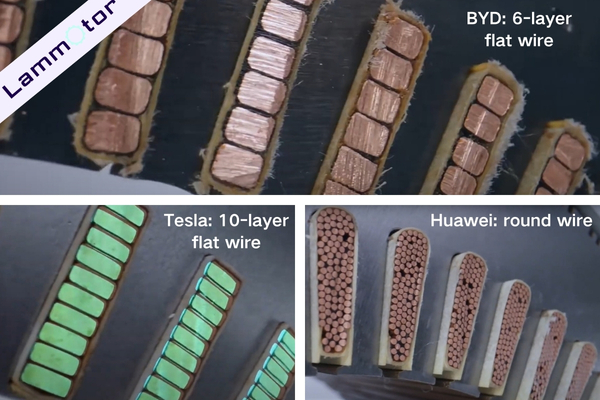

Tesla’s drive motor uses a 10-layer flat wire design in its PMSM. This layout improves copper utilization, enhances cooling, and helps balance low energy consumption with high power density.

The excellent acceleration, long range, and strong top speed of Tesla’s motors are closely tied to this flat wire structure.

BYD uses a 6-layer flat wire design, achieving better cooling and higher reliability under sustained high-load operation.

2. Laminated Rotor Design – Reducing Heat Buildup and Protecting Magnets

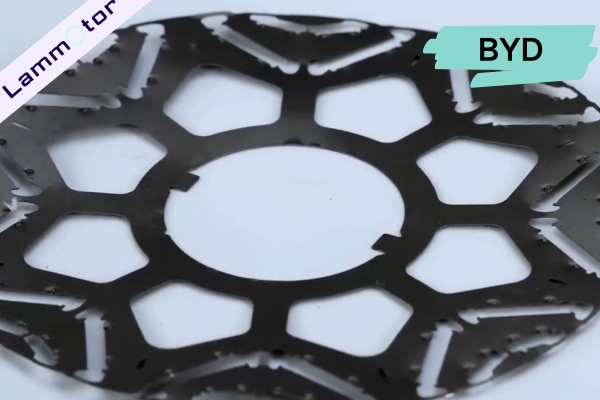

The rotor is where most heat concentrates. To reduce eddy currents and heat accumulation, manufacturers use laminated rotor technology.

This process stacks dozens or even hundreds of ultra-thin silicon steel sheets—each as thin as 0.2–0.3 mm—to form the rotor core.

These laminations interrupt electrical loops, reduce iron loss, and significantly lower rotor temperature.

Tesla and Huawei use 0.28 mm and 0.25 mm silicon steel laminations in their motors, while BYD goes even further with 0.2 mm laminations and adds trace amounts of silicon to control conductivity and improve thermal performance.

By reducing heat inside the rotor, laminated structures protect the permanent magnets from high temperature damage and ensure stable performance even at high RPM.

3. Oil Cooling Systems – Deep Cooling from the Inside

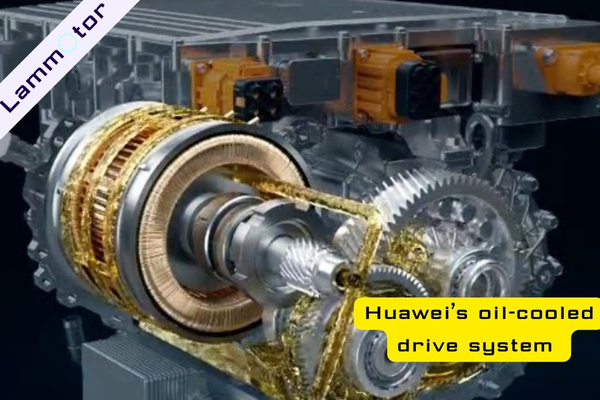

Why do more manufacturers turn to oil cooling instead of water cooling? Because oil can reach areas where water cannot.

Water-based coolants cannot directly touch internal components since they conduct electricity and may cause corrosion or short circuits.

Oil, however, is non-conductive and non-magnetic, allowing it to flow directly through critical areas such as the stator windings and rotor cavity, removing heat right at the source.

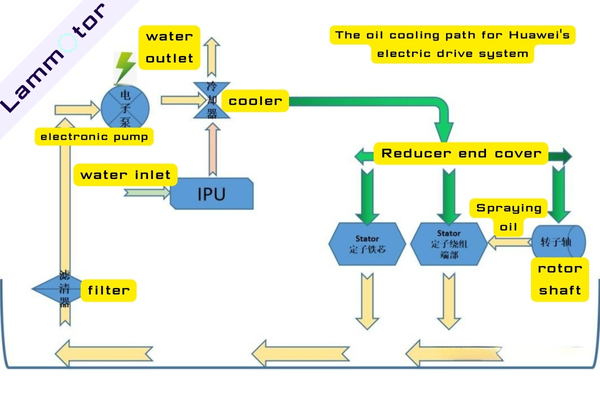

Huawei’s oil-cooled drive system uses active oil circulation for both the stator and rotor.

Cooling oil is sprayed directly through the rotor shaft, stator core, and winding ends, lowering the average peak temperature by about 30°C.

This design allows the motor to sustain repeated full-power acceleration and high-speed driving with minimal thermal decay — a major advantage over traditional water-cooling methods.

Conclusion: Cooling Defines the True Power of Electric Motors

Around the world, automakers and motor suppliers are pushing forward innovations in electric motor cooling.

Although cost and material challenges remain, improvements in cooling technology are unlocking new levels of performance and reliability.

As advanced materials, smarter control systems, and cost-effective cooling techniques continue to develop, the day will come when electric motor cooling is no longer a bottleneck — and when that happens, motor performance will experience a true breakthrough.

Let’s Talk About Your Motor Project

Efficient electric motor cooling starts with the right design of stator and rotor cores.

At Lammotor, we specialize in manufacturing precision drive motor stator and rotor cores optimized for cooling and performance.

If you need a custom solution for your EV motor or drive system, contact us today — let’s build the future of efficient electric drive motors together.