Synchronous Reluctance Motor Laminations Manufacturer in China

As a professional manufacturer of Synchronous Reluctance Motor Laminations in China, we specialize in producing high-quality stator and rotor lamination stacks for industrial and automotive applications.

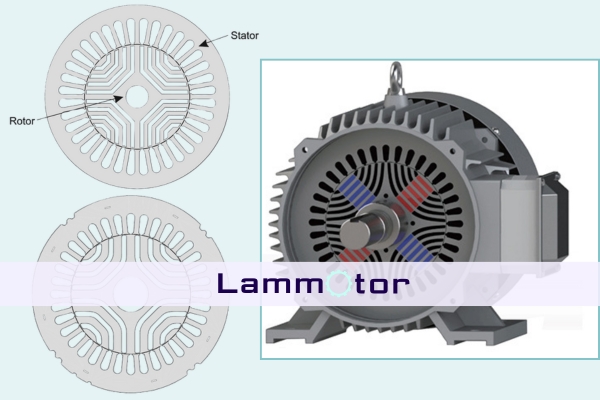

The Synchronous Reluctance Motor (SynRM) is a type of synchronous motor that generates torque based on the “principle of minimum reluctance.” Its rotor features a unique salient-pole structure, enabling the motor to operate with high efficiency, reliability, and low maintenance requirements—without the need for squirrel-cage windings or large quantities of permanent magnets.

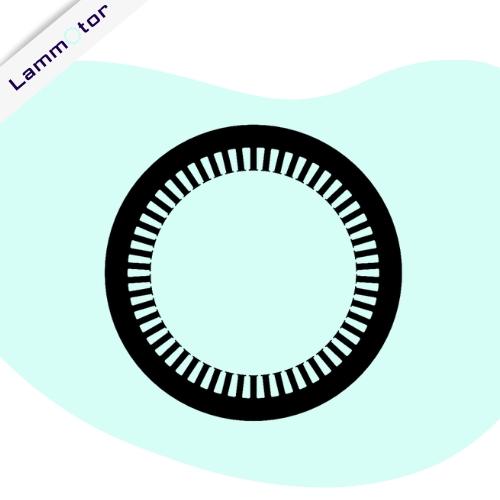

Customize Synchronous Reluctance Motor Stator and Rotor Laminations

We provide customized Synchronous Reluctance Motor Cores tailored to your project requirements. The SynRM rotor contains no permanent magnets and no squirrel-cage bars, while the stator is a conventional laminated stator. The motor relies purely on reluctance torque, making it simpler, lighter, and easier to maintain.

Compared to induction motors of the same power, laminated SynRM cores offer a more compact size and can achieve IE5 efficiency levels. The absence of magnets and die-cast aluminum also reduces manufacturing complexity and improves service life.

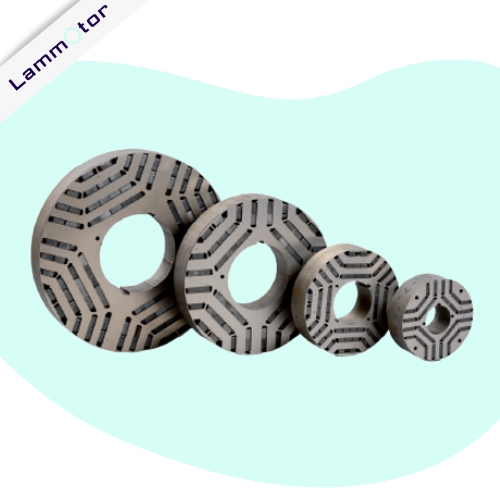

Our engineering team has produced a wide range of synchronous reluctance stator and rotor cores for various applications, including industrial machinery, pumps, compressors, and electric vehicle traction motors. If you need Synchronous Reluctance Motor stator and rotor for your next project, we can provide complete design, prototyping, and mass production services.

In addition, Permanent Magnet Assisted Synchronous Reluctance Motors (PMaSynRM) combine reluctance torque with permanent magnet assistance, using cost-effective ferrite magnets instead of rare-earth materials—making them ideal for high-end industrial synchronous motor series.

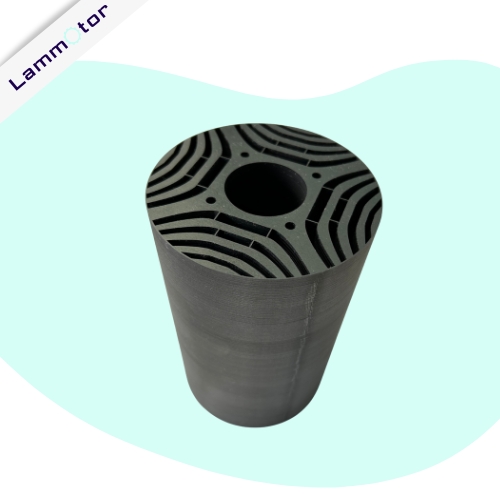

bonding Synchronous Reluctance Motor Rotor

Permanent Magnet Assisted Synchronous Reluctance Motor Rotor Cores

Synchronous Reluctance Motor Stator Lamination

Synchronous Reluctance Motor Rotor Stacks

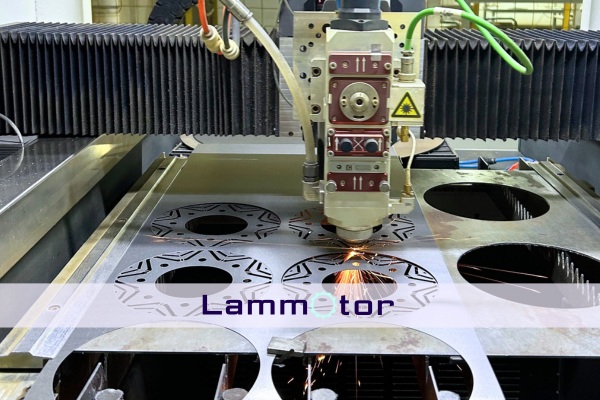

Manufacturing Process for Synchronous Reluctance Motor Laminations

For small-batch and prototype production, we offer precision manufacturing processes such as laser cutting, wire EDM. Also, for prototypes, normally, we will provide the bonding method for stacking.

Other Motor Core Lamination Products

Contact Us for Synchronous Reluctance Motor Laminations Solutions

Whether you need prototype development or mass production, our team can deliver high-performance Synchronous Reluctance Motor Cores with competitive pricing and fast lead times. Contact us today to discuss your requirements.