rotary notching Lamination Stacks For Motor Core in china

We proudly offer rotary notching services for motor core lamination to customers who need reliable and accurate results. Our rotary notching machines can be used on many materials, such as silicon steel and nickel alloys – perfect for motors or other electrical equipment laminations. We take pride in offering fast turn-around times while ensuring accuracy with each notch we make.

Our Rotary Notching Capabilities For Motor lamination Stacks

Rotary punch is one of our core competencies. It is a very economical choice for large and medium-sized motor patch production. The maximum outside diameter of our products is up to 1250mm. We use the rotary notching process to create precision and consistent notches on different shapes and sizes of laminations.

We have extensive experience in manufacturing big motor cores for various automotive, aerospace, electronics, and military industries. Our team of engineers ensures quality assurance from start to finish, ensuring high-quality products with precision notches.

materials used in stator and rotor lamination Stacks

We offer a wide range of materials to ensure the best possible results. Our selection includes silicon steel, cobalt, and nickel alloys, which are renowned for their superior performance.

Silicon steel provides benefits such as low core losses and high permeability. Cobalt alloys are known for their strength and resistance to magnetization reversal, while nickel alloys offer good ductility and temperature resistance.

With our materials at your disposal, you can be confident that your motor will function reliably over an extended period with little maintenance required.

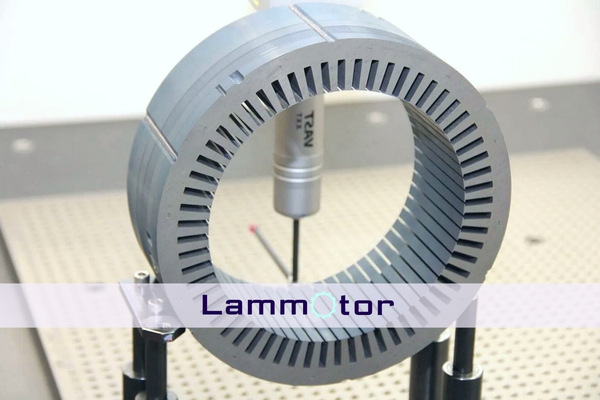

Comprehensive Testing Services

quality control

We have a strict inspection process to ensure the quality of motor lamination stacks.

First, we use quality materials when manufacturing their motor laminations, which will help guarantee that they remain effective and reliable over time.

Second, we accurately measure and monitor each part of the process.

This means taking precise measurements before, during, and after lamination to ensure that all components have been cut properly and adhere to set specifications.

Our testing equipment includes the projector, CMMs, a tension meter, a vernier caliper, and so on.

Finally, we also inspect their completed motors thoroughly before shipping them out.

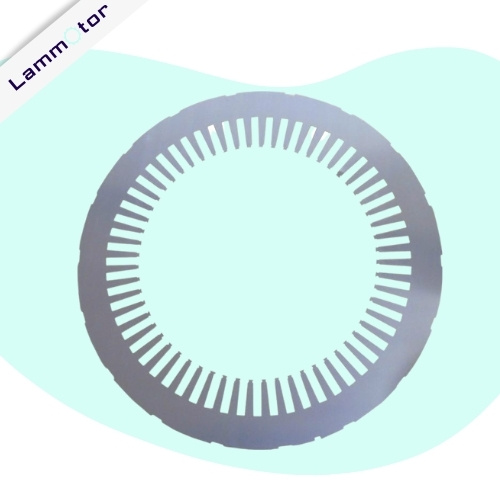

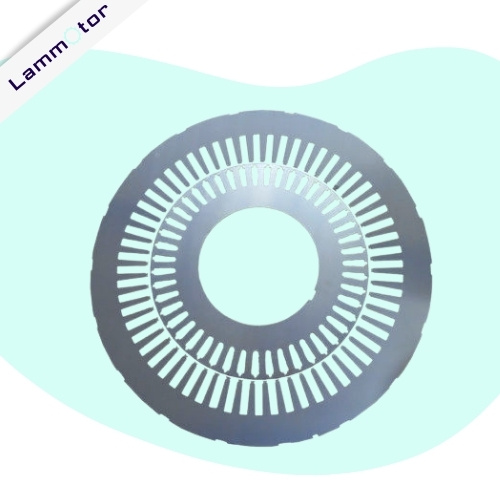

A series of stator & Rotor lamination Stacks we customized

We can manufacture various types of motor cores using rotary notching motors. Single-slot stamping is a suitable method for stator laminates with large outside diameters and large sample sizes.

OUR SERVICES

why choose us for electric motor lamination stacks?

We can provide custom solutions for any lamination needs. Besides standard motor stator and rotor lamination, we can also produce customized laminations.

high precision

Our stamping sizes range from 4 mm outside to 1250 mm, and the lamination tolerance range is ±0.005 mm. So you can be sure of getting high-precision results from us.

strong stamping capabilities

We have a strong stamping capability that can meet your specific needs. It includes progressive, compound, and hybrid stamping. And we offer welding, riveting, and gluing options for assembling your motor core.

cost-effective

We offer cost-effective rotary notching services for electric motor lamination. Our team of experts is committed to providing you with the best possible results at competitive prices.

quality inspection

Our team of quality control experts inspects every lamination to ensure it meets the highest standards. Moreover, we have a 100% satisfaction guarantee. So you can be sure of getting the best possible results from us.

Rotary Notching Motor Lamination FAQs

What is rotary notching?

Rotary notching is a metal-cutting process that creates slots or grooves in laminates.

It typically involves using a rotary cutting tool such as an end mill or router, which spins at high speed and produces the desired slot shape.

This notching process can achieve curved slots and reduce the overall weight of the part.

Rotary notching is often utilized in motor core lamination services for motors and generators, allowing for precision cuts that optimize performance.

It is also commonly used in automotive parts production, electronic components, aerospace components, and more.

Advantages of rotary notching lamination Stacks For Motors

First, rotary notching offers a quick, reliable, and precise method of effectively cutting intricate shapes into sheet metal.

Second, rotary notching is suitable for low-to-medium volume production and prototype development. It can create complex shapes with precise accuracy, and its tool cost is relatively low compared to other processes.

The cost savings are even greater when longer runs are needed, making rotary notching an ideal option for lower-volume production requirements.

Contact us for rotary notching for stator and rotor laminations

We have a long-standing reputation for providing high-quality rotary notching services for motor laminations. We use the latest technology and quality materials to manufacture rotary notched stator and rotor laminations, which ensure optimal performance and safety.

Our engineers can design rotary notches for electric motors of any size, shape, and configuration to optimize efficiency and performance. If you are looking for electric motor lamination rotary notching services, contact us today!