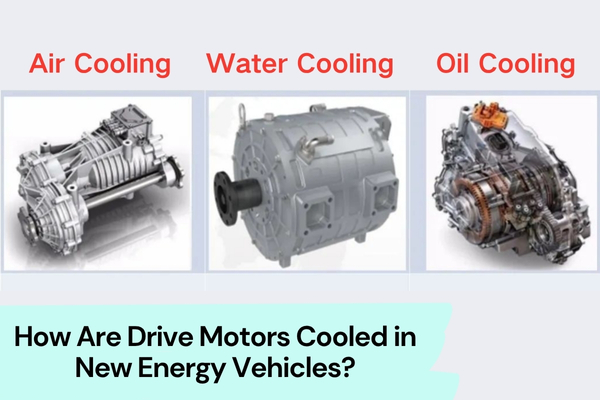

How Are Drive Motors Cooled in New Energy Vehicles?

As a drive motor manufacturer with years of experience in motor cooling system design, I often get asked: how do electric vehicles manage the enormous heat generated by high-performance motors? Whether it’s a pure electric car or a hybrid, e-drive systems deliver impressive acceleration and power—but they also bring significant cooling challenges. So how are these heat issues solved?