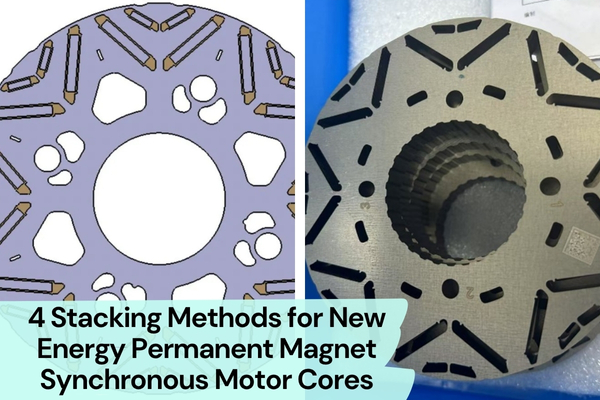

How do the stacking methods of stator and rotor cores affect the performance of a new energy vehicle motor?

As a core lamination designer with years of experience, I often encounter this question. In fact, the stacking method directly influences the efficiency, reliability, noise level, and cost of EV motors.

Choosing the right method is critical—especially for high-performance permanent magnet synchronous motors (PMSM) used in electric vehicles.

In this article, I’ll walk you through four mainstream stacking methods used in PMSM cores, and share insights into their pros, cons, and future development trends.

If you’re looking to better understand motor core technologies for new energy vehicles, keep reading.

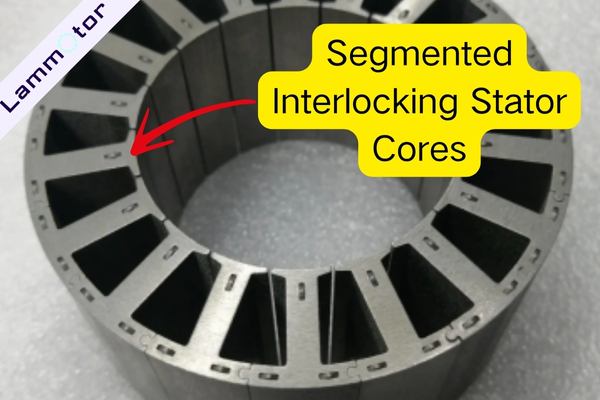

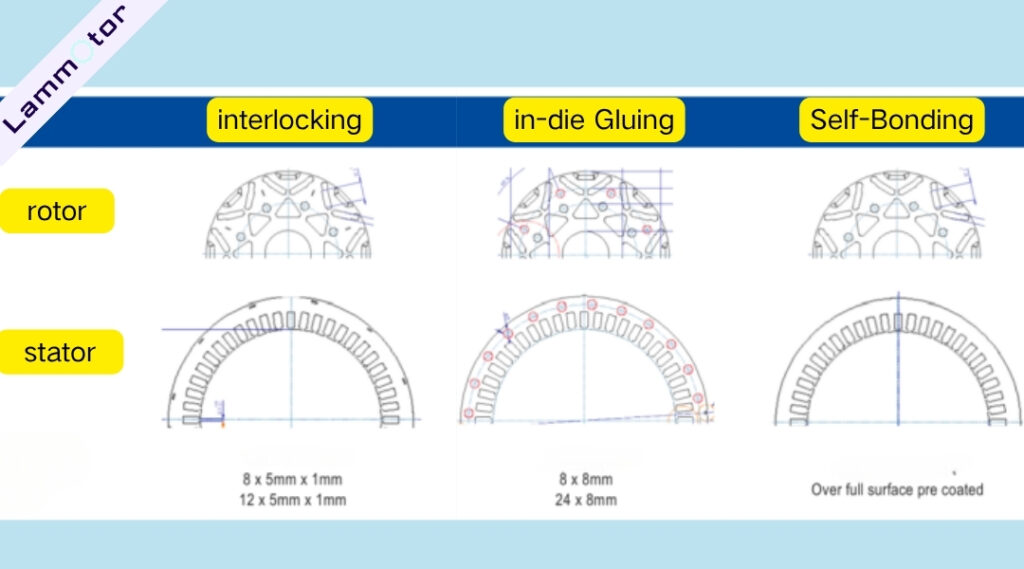

1. Segmental Interlocking Stator Cores

Segmental interlocking structures are commonly used in stators with concentrated windings. This design divides the stator core into multiple segments and uses interlocking features to fix them together. It allows for efficient use of materials and is suitable for wider slots typically found in concentrated winding designs, where integral punching would be more costly.

However, this method disrupts the continuity of the magnetic circuit, leading to poorer NVH performance and overall motor efficiency compared to integral punching. As the industry gradually shifts away from concentrated winding motors, this interlocking method is now rarely seen in new energy applications.

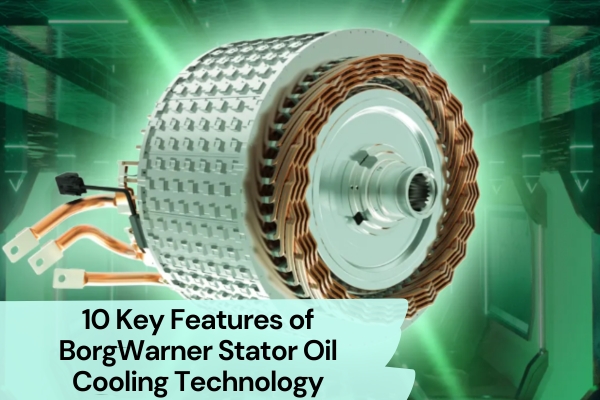

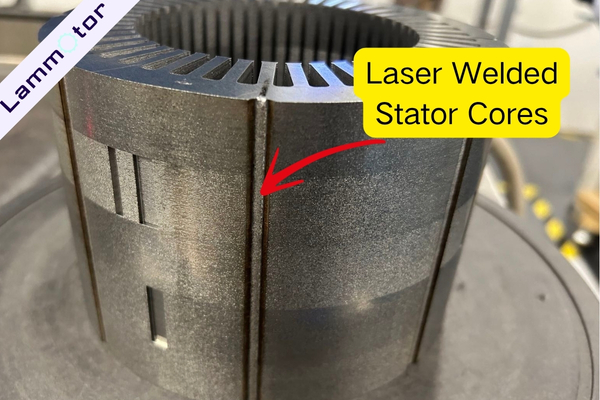

2. Welded Stator Cores

To overcome the disadvantages of segmented self-locking, most new energy motors now use stators made from full-punched laminations fixed by welding. This approach maintains the integrity of the magnetic path within the stator and increases the mechanical strength, preventing delamination during operation.

That said, welding can increase core loss during the process, reducing motor efficiency. Moreover, since the stator yoke is relatively narrow, welding may affect magnetic performance in critical areas.

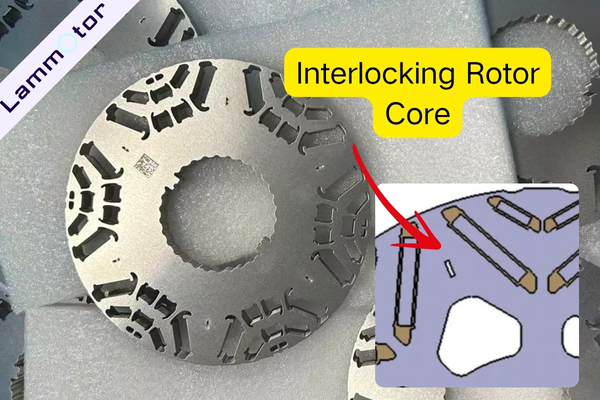

3. Interlocking Rotor Cores

For rotor cores, interlocking tabs are widely used because welding would interfere with the critical magnetic path from rotor to stator. These small tabs are placed in low-flux-density areas to bind laminations together.

While cost-effective, this method has relatively low strength and is prone to lamination warping. To avoid this, manufacturers often use press-fitted balance rings or overmold the core with plastic. These enhancements effectively improve durability but also increase production cost.

4. Self-Bonding or Adhesive Bonding

Self-bonding or adhesive bonding stacking is an emerging method that uses special glue applied between laminations. This technique combines the strengths of both welding and interlocking—while avoiding their weaknesses—offering a more reliable and high-performance solution.

Why Isn’t It Widely Adopted in EV Motors Yet?

Despite its advantages, adhesive bonding hasn’t seen mass adoption in EV motors mainly due to two challenges:

Cost: Special adhesives used in this method increase production cost. Thus, minimizing glue usage is crucial.

Technical: High-temperature resistance and uniform glue coating are critical. Excess glue can reduce the stacking factor, impacting motor performance.

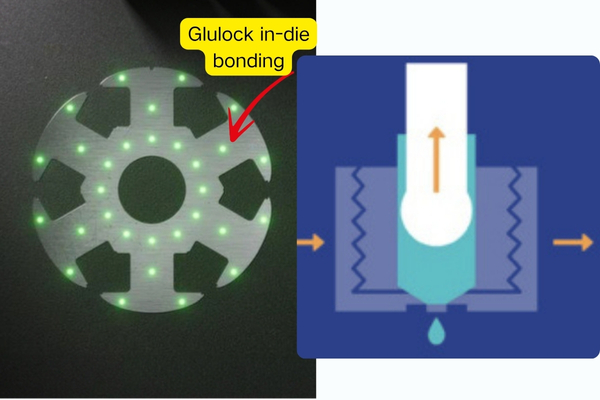

Glulock: A Technical Breakthrough by Feintool

Feintool’s Glulock in-die bonding technology offers an effective solution to these issues.

Cost Control:

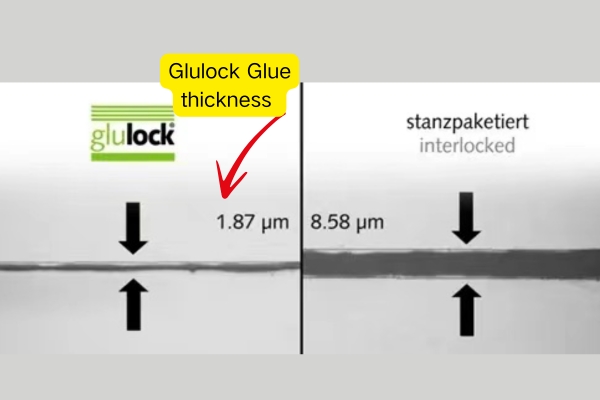

Ultra-precise coating: Glue thickness is controlled under 2μm—far thinner than the industry average of 8μm—allowing for significant cost savings.

Preserved insulation: The adhesive process avoids damaging the silicon steel’s insulation coating, reducing core loss by at least 10% and enabling the use of lower-grade steel to cut costs.

Higher core stiffness: The bonded stack has over 75% higher natural frequency, improving motor rigidity and enabling downsizing of balance rings.

Higher yield: This method improves stator and rotor core integrity, reducing rework and scrap during production.

Technical Advantages:

Gluelock HT adhesive withstands 180°C and resists oil, water, and chemicals—ideal for oil-cooled motors.

Consistent glue application ensures uniform stacking and supports mass production. The technology has already gone through three iterations and is used in several luxury EV models in Europe.

Stacking factor of 98%, comparable to welding, and higher than typical adhesive stacks (96%).

Combined with Feintool’s precision tooling to control roundness and concentricity, the bonded cores offer exceptional geometric accuracy.

Contact Lammotor for EV Motor Stator And Rotor Cores

Currently, laser welding and interlocking are the most commonly used stacking methods in PMSM for EVs. However, as adhesive technologies mature and costs decline, self-bonded laminations are expected to become more widely adopted in the near future.

We specialize in manufacturing EV motor stator and rotor cores using all four of the stacking methods mentioned above. If you’re looking for a reliable partner to develop high-performance EV motor laminations, contact us today. Let’s power the next generation of electric vehicles together.