In recent years, many automakers have talked about applying axial flux motors in new energy vehicles. But due to manufacturing difficulties and high costs, most companies were still waiting and watching.

However, at this year’s Shanghai Auto Show, several companies showcased their axial motor products. Let’s take a look together. Personally, I see great potential for axial flux motors as range extenders. They can make the range extender system smaller and more compact. Chery and InfiMotion have already made progress in this area.

1. Valeo

At the show, Valeo presented a thinner, smarter, and more efficient axial flux generator. They also announced a new partnership with Pangood Power to jointly develop the next generation of products. The two companies will combine Pangood’s structural design expertise with Valeo’s advanced inverter technology to speed up the application of electrification solutions in range-extended electric vehicles.

Valeo’s axial flux generator system reduces size by up to 50% and achieves 97% efficiency.

2. Pangood Power

Pangood Power brought two new axial flux motors to the 2025 Shanghai Auto Show, featuring ultra-high speeds and power density. One of them, the ICD306K motor, delivers a peak power of 306kW and a maximum speed of 18,000 rpm. Its effective power density is over 21kW/kg, and torque density is 32.5N·m/kg.

The ICD306K has set a new benchmark for axial flux motor peak speeds. This proves Pangood’s innovation in axial flux motor design and manufacturing.

A dual ICD306K motor drive system has an axial length under 500mm and a total weight under 95kg. The peak power reaches 612kW, giving it a leading power density of 6.4kW/kg.

Another highlight is the PDS560DM dual motor system based on the ICD280K. Compared to typical 700-800mm axial sizes, the PDS560DM has a compact 500mm axial length with 560kW peak power. This compact yet powerful setup offers clear advantages.

3. Shanghai Edrive Co.,Ltd

This axial flux motor is ideal for range extender systems. It features high power density, light weight (30%-50% smaller and lighter), high efficiency, and low core loss. With excellent cooling and modular design, it connects directly to combustion engines. It also performs well in noise and vibration control.

Key specs:

- Voltage: 350V

- Peak Power: 91kW

- Peak Torque: 240Nm

- Max Speed: 6000rpm

- Working Voltage: 260V~420V

- Max Efficiency: 95.6%

4. Schaeffler

Schaeffler showed a compact high-performance axial flux motor. It delivers 250kW peak power and 480Nm peak torque (350Nm continuous), weighing just 33kg. The rotor has low inertia (0.036kgm²). It uses direct oil cooling and an efficient air-cooled yokeless rotor design, achieving high power in a small package (306mm outer diameter, 93mm length).

5. Chery

Chery presented its Kunpeng Golden Range Extender CEM system, using an axial flux oil-cooled motor for power generation. This is the same motor technology used in high-performance cars like the Koenigsegg Regera and Rimac Nevera. The axial flux motor is efficient, compact, and lightweight.

With Chery’s own Kunpeng Tianheng engine, the CEM system allows flexible layouts and better performance. A standout feature is its use in amphibious vehicles.

Just half a year ago, Chery had only a prototype. Now it has combined the engine and motor into a working range extender. This is a key direction for future development.

6. CATL

CATL unveiled its flagship skateboard chassis – the “Rock Chassis” – featuring a dual motor distributed drive system with axial flux motors.

This setup delivers 6200Nm peak wheel torque and 500kW peak power. It supports 320kW continuous output and accelerates from 0-100km/h in under 5 seconds. Max speed: 280km/h.

The motor measures 235mm, with system dimensions of 430×485×320mm. In the same space, power output doubles and torque increases by over 50%, thanks to the axial flux motor design.

Key specs:

- Peak Power: 250kW × 2

- Peak Torque: 350–435Nm × 2

- Max Speed: 18,000rpm

- System Torque: 6,200-10,000Nm

- Independent torque vectoring control

- SiC 800V power modules

- Multi-link + air suspension system for ride comfort

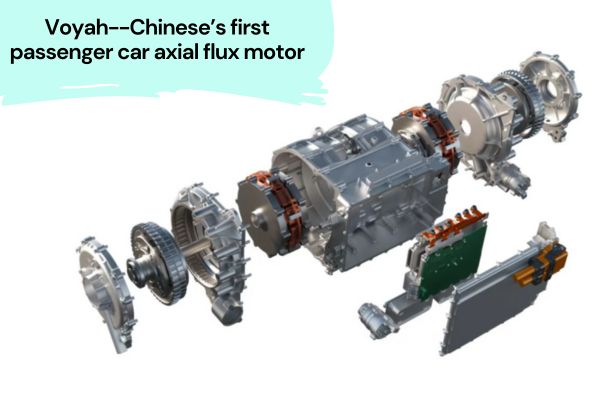

7. Voyah

Voyah released its L3-level intelligent platform, Tianyuan Smart Architecture, at the auto show. Its Qingyun safety platform uses an axial flux motor with a peak torque of 680Nm and weighs just 28kg. The motor has a volume of only 9.9L and reaches 97.5% efficiency.

It helped test vehicles tackle 60% slope challenges, start on inclines, and turn on the spot. This greatly improves off-road ability and handling.

Voyah says this is the first axial flux motor used in China’s passenger car industry.

8. InfiMotion

InfiMotion displayed a high torque density axial flux motor. It can be used in EDU systems, as a direct-connect range extender motor, or even in aircraft propulsion systems. It has very wide application potential.

Conclusion

Axial flux motors offer big advantages. With the rotor placed beside the stator, their large diameter gives over 30% more torque density than traditional radial motors. They also use fewer materials for the same power, reducing cost.

Their compact and lightweight build helps increase EV range and improve space usage. The flat shape makes integration easy, and heat dissipation is strong.

In addition to electric vehicles, axial flux motors are also used in EVTOL.

If you would like to know Archer motor VS Joby motor, please click this link, it will help you to know more.

However, axial flux motors have strong magnetic pull between stator and rotor. Layered structures can reduce this, but they add complexity and cost. Also, the manufacturing process and quality control need more work before mass production.

Finally, very high power density poses new cooling challenges.

Still, the trend is unstoppable.