What gives modern trains the strong and lasting power to reach such high speeds?

To answer this question, we need to take a close look at the “power heart” of China’s high-speed rail — the Railway transportation traction motor. It is the key device that drives almost all forms of railway transportation.

The Railway transportation traction motor is the core equipment used on electric locomotives for mainline service, industrial locomotives, diesel-electric locomotives, and metro and urban rail vehicles. It takes on the tasks of starting, accelerating, braking, and supporting the whole running process of a train.

With the wide use of AC-DC-AC traction technology, modern railway vehicles mainly use AC traction motors, and they can be divided into two major types:

- Permanent magnet synchronous Railway transportation traction motor (PMSM)

- Induction Railway transportation traction motor (IM)

Below, we look at their structure, advantages, disadvantages, and practical applications in a clear and organized way.

1. Permanent Magnet Synchronous Railway Transportation Traction Motor (PMSM)

PMSM Structure

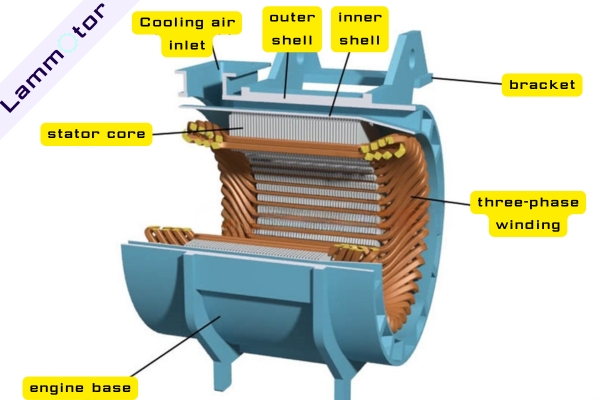

Motor housing

The motor housing uses an inner shell and an outer shell connected by support ribs. The inner shell holds the stator core. The outer shell has an air inlet at the rear and an outlet at the front. The space between the two shells forms a circular cooling air channel for airflow.

This design offers high strength, good cooling performance, and makes it easier to mount the motor on the bogie through the supporting brackets.

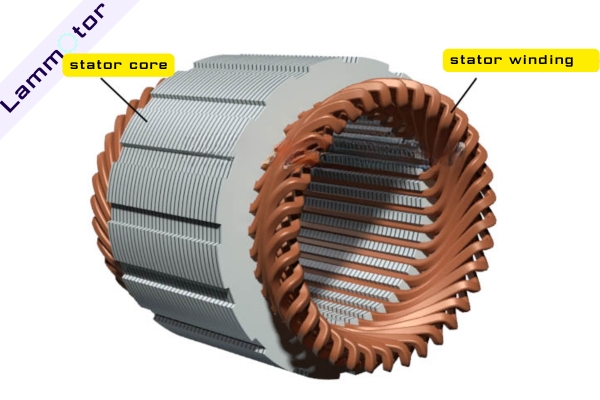

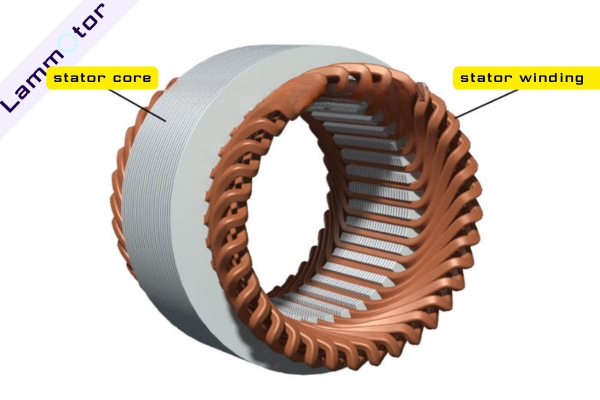

Stator

The stator is made from high-magnetic-permeability silicon-steel laminations. These laminations have insulation coating between them to reduce eddy-current loss under high-frequency magnetic fields.

The laminations are produced using high-precision punching or laser cutting to ensure accurate slot shape and slot pitch.

The stator’s outer circle fits tightly with the inner housing, and the inside holds either concentrated or distributed three-phase windings.

These windings use high-temperature-resistant copper wire. With slot insulation, phase insulation, and binding at the end windings, the stator maintains stability under strong electromagnetic force, temperature changes, and vibration.

After winding installation, varnish dipping or VPI (Vacuum Pressure Impregnation) is used to improve insulation strength and mechanical properties.

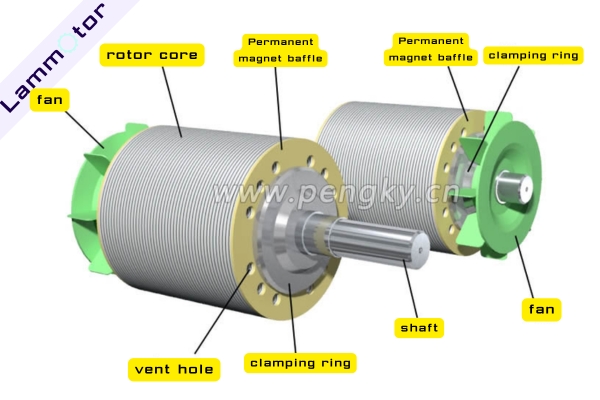

Rotor

The rotor of the permanent magnet synchronous Railway transportation traction motor consists of a laminated silicon-steel core, permanent magnets, and end structures.

The laminated core is made by stacking steel sheets. It includes embedded slots for the magnets and many radial and axial ventilation holes to improve cooling during high-speed operation.

The magnets are usually made of high-performance NdFeB. They are fixed tightly through mechanical locking, resin adhesive, or stainless-steel / carbon-fiber sleeves to prevent movement or cracking under vibration and centrifugal force.

Some high-speed models use carbon-fiber sleeves to increase magnet strength and reduce stress. Light end plates or clamping rings are installed on both ends of the rotor to ensure dynamic balance at high rotational speeds.

Advantages of PMSM

(1) High efficiency and high power factor

The magnets provide constant magnetic field, so no excitation current is needed. The rotor has no copper loss and produces less heat.

Efficiency is 3%–5% higher than that of an induction traction motor.

A high power factor reduces system losses and increases the train’s overall energy efficiency.

(2) Strong low-speed torque

The motor outputs high torque at low speed, making it very suitable for frequent start-stop conditions in railway transportation.

(3) High power density, smaller size, and lighter weight

For the same output power, PMSMs can be about 30% smaller and lighter than induction motors. This makes layout easier, reduces unsprung mass, and even allows direct mounting near the wheel, making direct-drive systems possible.

(4) Low noise and good energy-saving effect

A PMSM usually has a fully enclosed structure. Airflow resistance is low, noise is small, and high efficiency can be maintained over the entire operating range.

Disadvantages of PMSM

(1) Risk of demagnetization

Permanent magnets are sensitive to temperature. High temperature or strong impact may cause irreversible demagnetization.

Possible reasons include:

- Eddy-current loss caused by high current

- Harmonic loss

- Vibration leading to cracks or loosened magnets

These problems must be solved through thermal isolation, stronger structures, and optimized magnetic design.

(2) Higher control requirements

Since PMSMs do not have slip, train operation must use “axle control” to synchronize all motors.

Multi-motor control is more difficult and needs advanced control algorithms, including:

- Power-off and re-energizing control

- Online parameter identification

- Accurate torque control

Large-scale use of PMSMs in railway transportation depends heavily on improvements in control-system reliability.

2. Induction Railway Transportation Traction Motor

Induction Traction Motor Structure

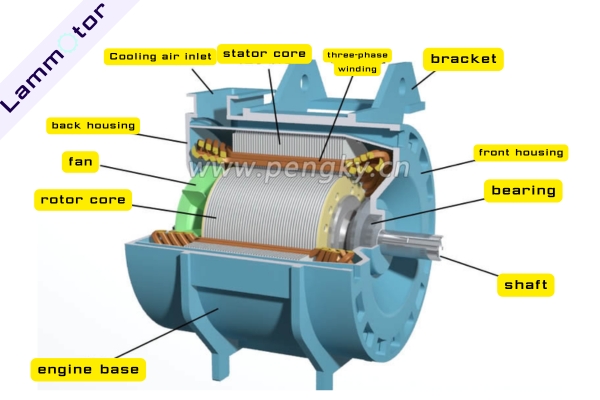

Motor housing

The housing of an induction Railway transportation traction motor is usually made by casting steel or aluminum. Strengthening ribs increase resistance to vibration and impact.

Brackets on the housing help mount the motor under the bogie. The space between the inner and outer shells forms an air channel to cool the stator, rotor, and windings.

The front and rear of the housing connect to end covers. These covers maintain mechanical strength and form a complete cooling-air path for stable long-term operation.

Stator

The stator consists of stacked silicon-steel laminations and three-phase windings.

The laminations are punched or laser-cut, and stacked with insulation between them to reduce core loss.

The windings use high-temperature enamel wire (H-class or above). Slot insulation, end winding binding, and varnish dipping ensure stability and reliability.

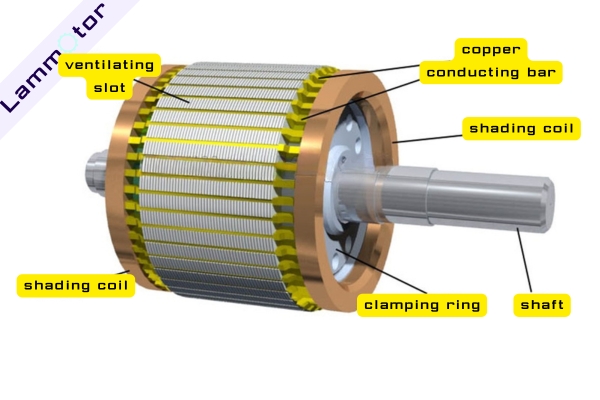

Rotor (squirrel-cage type)

The rotor is a squirrel-cage structure made of laminated steel, rotor bars, and short-circuit rings.

Ventilation holes allow air to pass through the core and reduce temperature.

The rotor bars (aluminum or copper) are inserted into the slots, and both ends connect to the short-circuit rings.

The shaft is hot-fitted to the rotor core, and end rings or plates improve mechanical strength and dynamic balance.

Advantages of Induction Traction Motors

(1) Mature control technology

- VVVF control allows:

- Constant-torque start for smooth acceleration

- Constant-power operation at high speed

This technology has been used for decades and is very reliable.

(2) Simple structure and high reliability

There are no magnets and no need for magnet protection. The structure is strong and requires little maintenance.

(3) Lower manufacturing cost

Induction motors do not use expensive rare-earth magnets, so cost is more controllable.

Disadvantages of Induction Traction Motors

The strengths of PMSMs are the weaknesses of induction motors:

- Lower efficiency

- Lower power factor

- Larger size and heavier weight

- Weaker low-speed torque

Cooling usually relies on forced-air cooling. A fan sends cold air into the air gap to remove heat from the stator and rotor.

Application of Railway Transportation Traction Motors

Today, high-speed trains, metros, and intercity trains widely use these two traction-motor types.

Induction traction motors are still widely used because they cost less and are very reliable.

Permanent magnet synchronous traction motors are growing fast due to their high efficiency and high power density.

Examples include:

- CRH380A/CRH380AL use induction traction motors

- New PMSM traction systems by CRRC Changchun and CRRC Zhuzhou are being used in metro trains and EMUs

Railway transportation traction motor technology continues to improve, and both types play important roles in modern rail systems.

Contact Us for Manufacturing Traction Motor Stator and Rotor Core

If you are looking for a reliable partner to supply high-quality stator and rotor cores for any Railway transportation traction motor project, we are ready to support you.

We offer professional manufacturing for both PMSM and induction traction-motor cores, and we can customize materials, lamination thickness, stacking methods, and insulation systems to meet your technical needs.

Whether you are developing a new traction motor or improving an existing design, feel free to reach out to us.