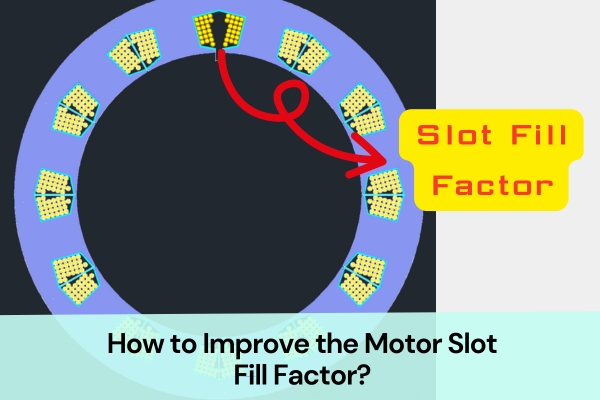

How to Improve the Motor Slot Fill Factor?

Are you trying to increase the motor slot fill factor but not sure where the real limits come from?

The motor slot fill factor is one of the most powerful tools we have when pushing power density, torque output, and efficiency. Small improvements often bring big gains. But to use it well, we must understand what controls it and how each design or process choice affects it.