Which eVTOL motor design is truly the better path forward? The debate between Archer motor VS Joby motor has drawn great attention in the electric aviation industry.

Archer Aviation and Joby Aviation have taken completely different technical routes for their eVTOL aircraft. One focuses on a high‑speed geared architecture similar to automotive drive systems, while the other pursues an ultra‑high torque direct drive solution.

But which approach makes more sense for reliability, performance, and commercial deployment? Let’s dive into Archer motor VS Joby motor designs in detail.

Archer Motor: High‑speed, geared, modular design

Archer, a U.S.‑based eVTOL company founded in 2018 in California, is both an aircraft OEM and an electric drive system developer. Unlike companies such as MagniX, Archer designs, develops, and manufactures its own propulsion units.

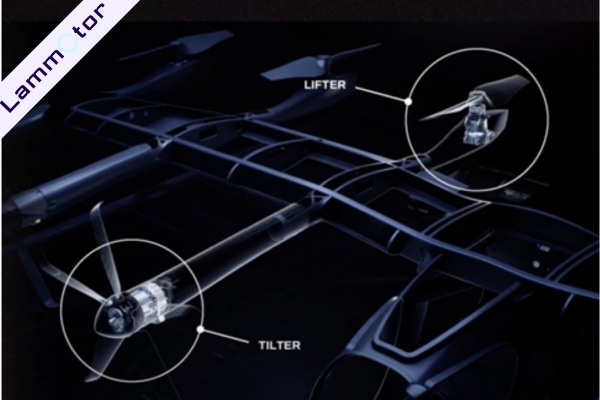

Its flagship Archer Midnight aircraft uses 12 radial flux permanent magnet outer‑rotor motors—six units on the wing leading edge for tilt function and six on the trailing edge for lift.

- Each electric motor delivers a peak power of 125 kW and weighs 25 kg, giving a power density of about 5 kW/kg.

- Failure of 1‑2 motors among the 12 has limited impact on total thrust, improving redundancy.

The motor drives a planetary gearbox and spins at 12,000 rpm, then steps down speed to drive relatively small five‑blade or two‑blade propellers.

Compared with Joby’s direct drive system, the geared solution is mechanically more complex with seven moving parts and requires lubrication, sealing, and periodic maintenance.

This approach resembles automotive electric drive systems but achieves much higher power density.

Key design features of the Archer motor

1. Coaxial integration of motor, gearbox, and inverter

Archer’s propulsion unit integrates the motor, planetary gearbox, and inverter in a compact coaxial design. Each motor is split into two redundant groups (A and B), and the inverter modules are installed independently in six groups. This modular redundancy is standard in aviation electric drives to ensure that partial failures don’t disable the entire system.

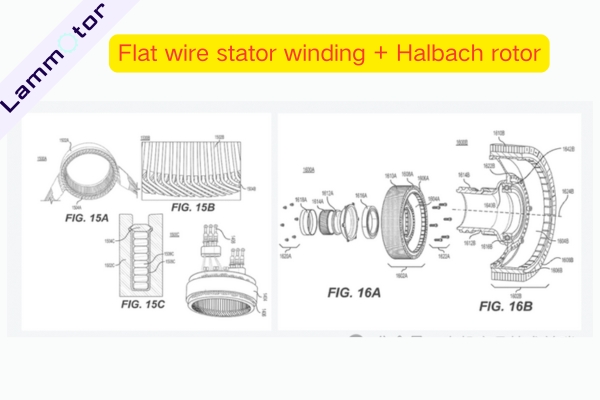

2. Flat wire stator windings + Halbach rotor

Archer uses flat wire windings for better copper fill and a Halbach array rotor to concentrate the magnetic field. This combination, common in high‑end automotive motors, significantly increases power density and efficiency. Compared with IPM rotor designs, the Halbach configuration has more linear inductance and better control stability, which is ideal for eVTOL applications.

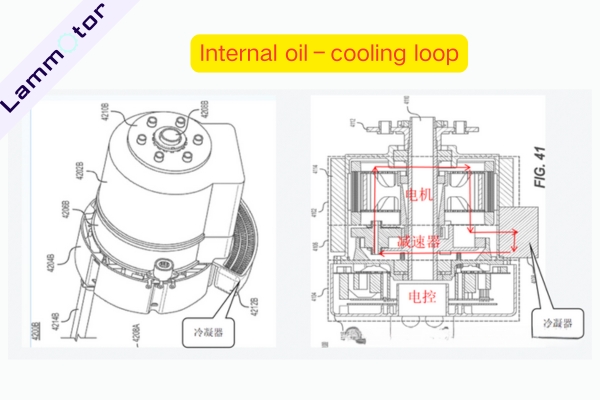

3. Internal oil‑cooling loop

Archer adopts a compact oil‑cooling internal circulation design. A condenser is placed outside the motor housing, cooled by propeller airflow, and oil is pumped through the gearbox and motor cavity to achieve efficient heat dissipation.

Joby Motor: Direct drive, high torque, extreme power density

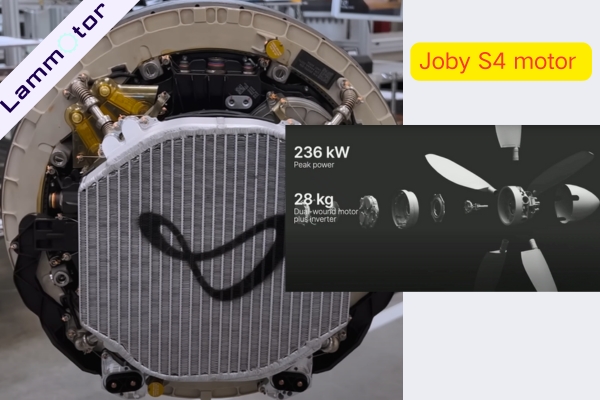

The Joby S4 aircraft takes a very different route. It uses six large direct drive radial flux outer‑rotor motors.

- Each motor delivers 236 kW peak power and weighs 28 kg (including inverter), achieving an impressive 8.4 kW/kg power density.

- Peak torque reaches 1,800 N·m, allowing the large‑diameter slow‑rotating propellers to run without a gearbox

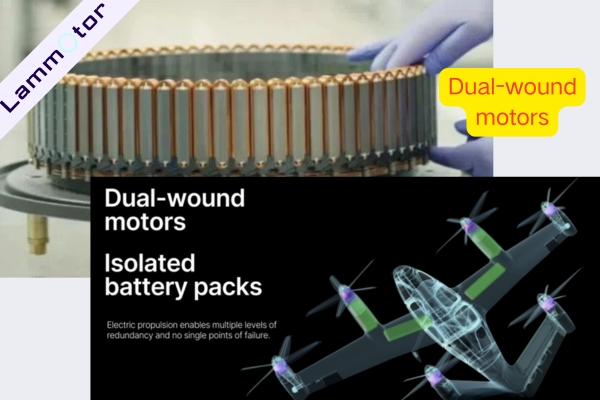

The motor uses a dual winding design, with the inverter mounted coaxially inside the motor housing. A three-channel liquid cooling system cools both the stator and the power electronics.

Each Joby propulsion motor is powered by a dual-redundant inverter setup to improve operational reliability. Within this setup, each inverter is connected to two separate battery packs, preventing a single battery failure from affecting the entire system. In total, four independent battery packs are installed, positioned away from passengers to enhance safety.

Key design features of Joby Motor

1. Direct drive high‑torque architecture

In 2017, Joby abandoned gear‑reduction designs and switched fully to a direct drive system. Each motor has just one moving part (a single bearing), reducing mechanical complexity and long‑term maintenance needs.

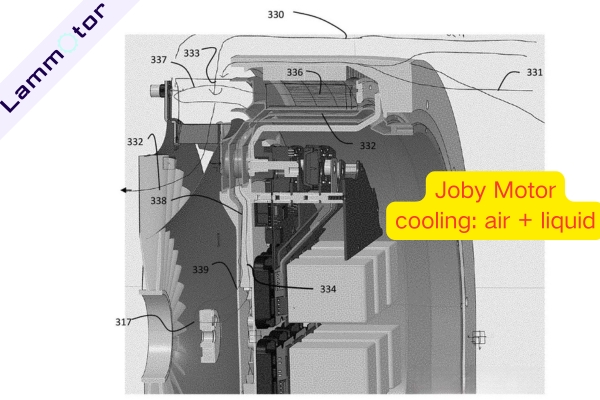

2. Motor cooling: air + liquid

Joby has revealed in its patents that its motor uses a combination of air cooling and liquid cooling.

First, the outer rotor and the inside of the motor are designed with multiple air channels, and there is an axial cooling fan located at the bottom of the motor. With the help of the fan and incoming airflow, the motor can be effectively cooled.

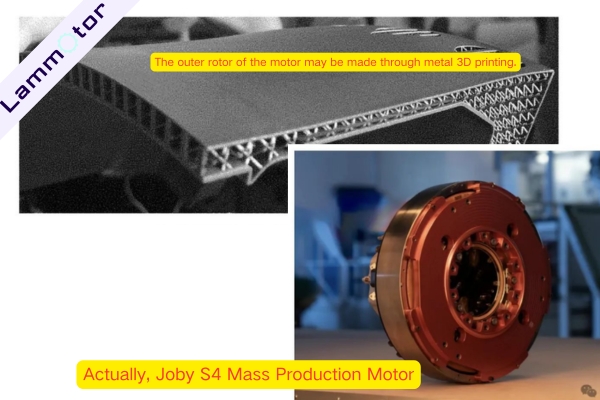

In addition, the outer rotor is designed with a mesh‑like internal structure. Air can enter from openings at the top or side of the rotor, flow through the mesh passages, and exit from the bottom, helping cool the rotor itself. This type of mesh outer‑rotor structure can be made using metal 3D printing.

However, based on the motors seen in actual production, the outer rotor does not appear to use 3D printing but rather conventional machining. As a result, the internal air‑cooling effect of the rotor may not be fully realized, although the other cooling methods remain in place.

3. Redundant power system

Each propulsion motor is driven by a dual‑redundant inverter, and each inverter is powered by two independent battery packs. Joby’s aircraft carries four isolated battery packs to ensure that any single battery failure doesn’t propagate.

4. Use of CoFe (cobalt‑iron) alloys

The rotor uses 1J22 cobalt‑iron alloy, which offers 20–30% higher magnetic flux density than conventional silicon steel. This enables a stronger magnetic field and higher torque for the same motor size.

Archer motor VS Joby motor: Which route is better?

From a system design perspective, the two approaches serve different goals:

- Archer focuses on modularity, redundancy, and faster mass production. Its geared motors align closely with automotive electric drive supply chains, lowering capital costs and leveraging proven gearbox compliance experience.

- Joby, on the other hand, pushes electromagnetic loading and power density to the extreme. The direct drive system eliminates gearboxes, reducing noise and long‑term maintenance, but requires much greater investment in cooling, insulation, and vibration validation.

For an eVTOL program aiming to deploy hundreds of aircraft in just three years, using components closer to mainstream automotive EV drives (like Archer’s design) could reduce initial capital expenditure. For premium passenger transport markets with a longer lifecycle focus, Joby’s custom high‑torque direct drive may ultimately be more cost‑effective.

Which approach do you think is more suitable for the next generation of eVTOL aircraft? Share your thoughts with us!

At Lammotor, we specialize in manufacturing brushless motor cores and axial flux stator cores. for eVTOL motors. If you’re developing eVTOL propulsion systems and need custom laminated motor cores, contact us today—our engineering team can support both prototype and mass production.