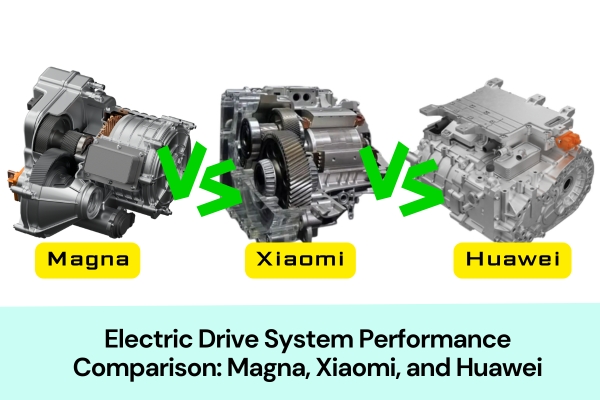

What makes an electric drive system truly powerful — efficiency, speed, or innovation?

As the EV industry evolves, the electric drive system has become the heart of every electric vehicle, directly shaping power output, energy efficiency, and driving performance.

Today, we’ll take a close look at three major players — Magna, Xiaomi, and Huawei — and compare their latest electric drive systems in terms of technology, performance, and engineering breakthroughs.

Magna High-Voltage Electric Drive System

For most consumers, Magna may not be a household name, but within the automotive industry, it stands among the top three global suppliers.

Magna designs and manufactures nearly every type of automotive component and even offers full vehicle engineering and production services.

In the field of electric drive systems, Magna has built a complete high-voltage product lineup covering 50 kW to 250 kW, supporting both 400 V and 800 V platforms.

Its modular architecture allows wide scalability and easy integration across different vehicle types, striking a balance between performance, efficiency, and flexibility.

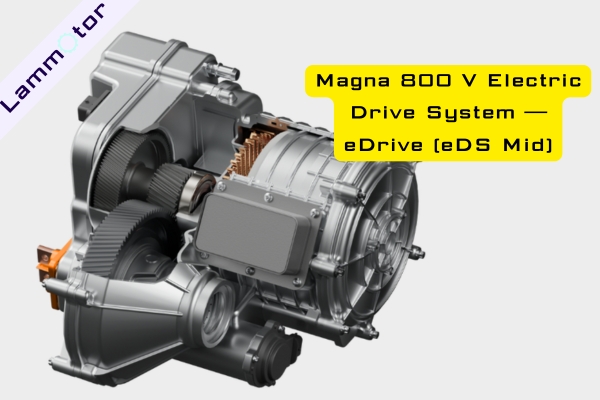

Magna 800 V Electric Drive System — eDrive (eDS Mid)

Magna’s newest 800 V eDrive system (eDS Mid) combines a compact high-speed motor with a SiC (silicon-carbide) inverter, delivering 100 – 140 kW output and up to 2,000 Nm torque.

Key Highlights:

- 800 V high-voltage architecture for faster charging and higher system efficiency.

- SiC inverter improves conversion efficiency by ≈ 5 % over conventional IGBT systems.

- Decoupling design enables fast AWD connection and smooth driving control.

- Lightweight for better packaging and energy use.

Specifications:

- Peak power: 250 kW

- Peak torque: 5,000 Nm

- Efficiency: > 93 %

- Weight: 75 kg

Mass production will start in 2026 for premium European SUVs and sedans, marking Magna’s strong step into high-efficiency 800 V electric drive systems.

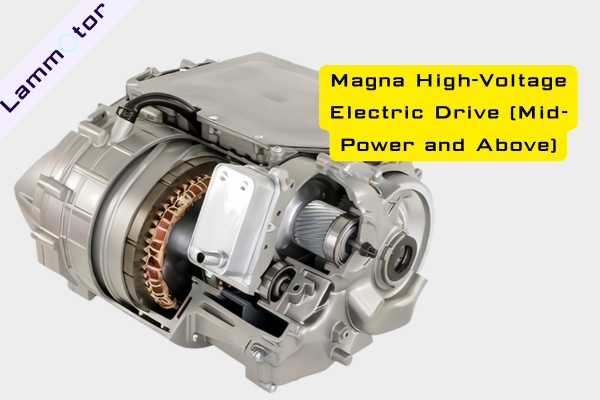

Magna High-Voltage Electric Drive (Mid-Power and Above)

This version targets the mid-to-high-end EV market.

Compared with similar products, it achieves 24 % less weight, 7 % more power, and 22 % smaller volume.

Features:

- High power-density design with > 95 % overall efficiency.

- Meets ASIL-D functional safety standards.

- Modular system suitable for C-, D- and E-class BEVs / PHEVs.

Specifications:

- Peak power: 180 kW

- Peak torque: 4,000 Nm

- Efficiency: > 95 %

- Product status: In mass-production stage.

Magna High-Voltage Electric Drive (Mid-Power, Low-Cost)

This series focuses on cost efficiency and lightweight design for medium to large EVs.

It uses a rare-earth-free permanent-magnet motor, reducing material dependency and cost.

Features:

- Supports 700 V battery systems.

- Compact three-in-one integration (motor + inverter + gearbox).

- Simplified structure makes vehicle packaging easier.

Specifications:

- Rated voltage: 700 V

- Peak power: 180 kW

- Peak torque: 3,000 Nm

- Product status: Engineering-design stage.

Magna High-Voltage Electric Drive (Mid-Power, High-Performance)

Designed for electric AWD systems, this complementary high-voltage drive emphasizes high output and fast response.

Highlights:

- Produced in carbon-neutral European facilities.

- Dual-motor complementary design for performance and efficiency.

- Targeted at C- and D-class high-performance EVs.

Specifications:

- Power range: 120 – 150 kW

- Status: Engineering-design phase.

Magna High-Voltage Electric Drive (Low-Power)

Aimed at entry-level EVs and auxiliary AWD applications, the low-power version supports the 800 V platform and maintains compact dimensions.

Features:

- For C- and D-class EVs as front / rear drive units.

- Lightweight, high-efficiency structure.

- Produced with low-carbon manufacturing.

Specifications:

- Power range: 80 – 120 kW

- Status: Pre-production stage.

Xiaomi Electric Drive System

Xiaomi’s transition from electronics to EV manufacturing surprised many, but its depth of R&D quickly proved real strength.

The company has developed three high-performance “Super Motor” models — V6, V6s, and V8s — representing continuous breakthroughs from 400 V to 800 V electric drive systems.

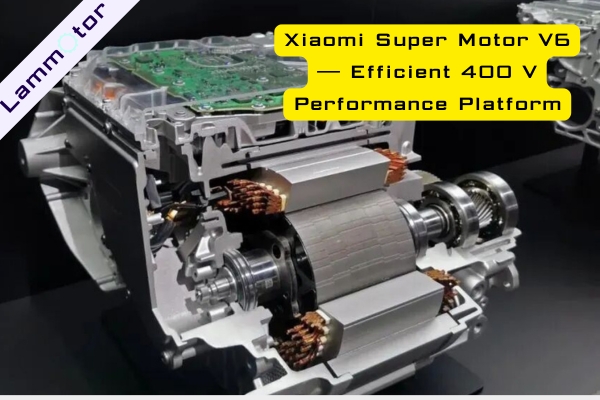

Xiaomi Super Motor V6 — Efficient 400 V Performance Platform

Co-developed with United Automotive Electronics and Inovance, the V6 targets the mid-to-high-end EV segment.

Highlights:

- 21,000 rpm maximum speed for instant acceleration.

- Compact three-in-one integration (motor + gearbox + controller).

- Separate water-cooling circuits for motor and reducer to enhance stability.

- High-precision rotor balancing for better NVH performance.

Specifications:

- Max horsepower: 299 PS

- Max power: 220 kW

- Max torque: 400 Nm

- Max speed: 21,000 rpm

Xiaomi Super Motor V6s — Upgraded 800 V Platform

The V6s retains the compact architecture of V6 but upgrades to an 800 V high-voltage platform, boosting both power and efficiency.

Highlights:

- 800 V system architecture for faster charging and less energy loss.

- Peak power increased to 275 kW.

- SiC inverter for higher conversion efficiency.

- Improved gear design for quieter operation.

Specifications:

- Max horsepower: 374 PS

- Max power: 275 kW

- Max torque: 500 Nm

- Max speed: 21,000 rpm

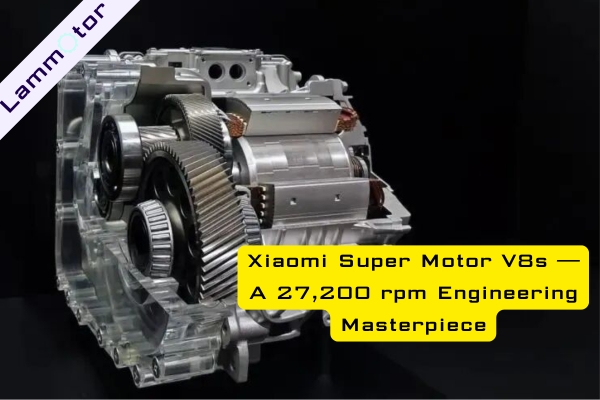

Xiaomi Super Motor V8s — A 27,200 rpm Engineering Masterpiece

While most 400 V motors top out around 16,000 – 17,500 rpm, and even Tesla’s 800 V system reaches only ≈ 20,000 rpm, the Xiaomi V8s achieves a record-breaking 27,200 rpm.

This extraordinary speed comes with 425 kW peak power and 635 Nm torque, giving it one of the highest power densities in its class — 10.14 kW/kg with efficiency of 98.11 %.

Re-engineered Stator and Rotor Design:

- 54-slot, 6-pole configuration for balanced magnetic flux.

- Pin-type flat-wire winding for tighter packing and better heat transfer.

- Slot fill factor increased to 77 %; core loss reduced 25 %.

Advanced Cooling System:

- Dual-loop oil-cooling design around stator windings and ends.

- S-shaped rotor cooling channel to expand heat exchange area.

- Max temperature reduced by 30 °C and overall thermal efficiency up 50 %.

Specifications:

- Power density: 10.14 kW/kg

- Max horsepower: 578 PS

- Max power: 425 kW

- Max torque: 635 Nm

- Max speed: 27,200 rpm

- Max efficiency: 98.11 %

The V8s proves that Chinese manufacturers can reach global-class engineering standards in high-speed, high-power-density electric drive systems.

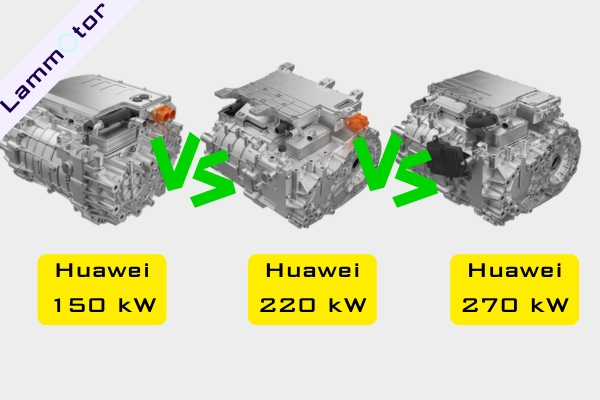

Huawei Three-in-One Electric Drive System

Huawei’s DriveONE platform embodies its concept of “smart integration.” It merges the motor, controller, and reducer into a compact unit and offers 3-in-1, 5-in-1, and 7-in-1 configurations.

The series covers 150 kW to 270 kW, serving A0 to C-class vehicles with both permanent-magnet and asynchronous motors.

Huawei 165 kW Three-in-One Electric Drive System

Integrates the MCU, asynchronous motor, and reducer in a small, lightweight package.

Using IGBT dual-side water cooling plus intelligent oil cooling, it achieves 3,400 Nm peak torque and 90 % efficiency, improving vehicle power and range.

Huawei 150 kW Three-in-One System

Uses a permanent-magnet motor and supports 200 – 470 Vdc input.

Compact and light, it fits multiple EV platforms and improves installation flexibility.

Huawei 220 kW Three-in-One System (Asynchronous)

Targets higher-performance EVs, covering 492 – 748 Vdc voltage range.

Lightweight design ensures easy integration and stable thermal performance under heavy load.

Huawei 270 kW Three-in-One System

Employs a permanent-magnet motor for maximum output of 270 kW.

Suitable for high-performance EVs needing greater torque and speed.

For the B+ class extended-range hybrid market, Huawei introduced the industry’s first 165 kW asynchronous five-in-one drive assembly at its 2023 Smart Electric Launch Event.

This system is designed for high overall efficiency and features 26% lower drag torque compared to the industry average. It is also the first in the industry to integrate dual controllers, a generator, an asynchronous drive motor, and a reducer into a single compact unit.

Its power density is 20% higher than similar products on the market and is optimized for vehicles using double-wishbone suspension.

When combined with Huawei’s 200 kW synchronous three-in-one drive system, it can form a dual-motor hybrid or high-performance AWD system, achieving 88.2% WLTC efficiency — about 5% higher than the industry standard — and increasing total driving range by 44 km under full fuel and battery conditions.

Build Your High-Performance Electric Drive Motor Core with Us

At Lammotor, we specialize in manufacturing precision stator and rotor cores for all kinds of electric drive systems.

From laser cutting, wire-EDM, stamping, bonding, laser welding to interlocking, we provide complete in-house solutions.

Whether your project involves high-speed motors, flat-wire motors, or 800 V EV applications — we can help you achieve higher efficiency and lighter designs.

📩 Contact us today to develop your next-generation electric drive system motor cores together!