What materials are used in transformer cores and how do they impact performance? Choosing the right core material is essential for ensuring transformer efficiency, reducing energy losses, and optimizing overall functionality. As a transformer lamination manufacturer in China, we understand the importance of selecting the right material for different transformer applications.

This blog’ll explore five core materials—each with unique properties and benefits. By the end, you’ll clearly understand which materials are best suited for your specific needs, whether it’s maximizing energy efficiency or minimizing costs.

1. Silicon Steel: The Most Widely Used Transformer Core Material

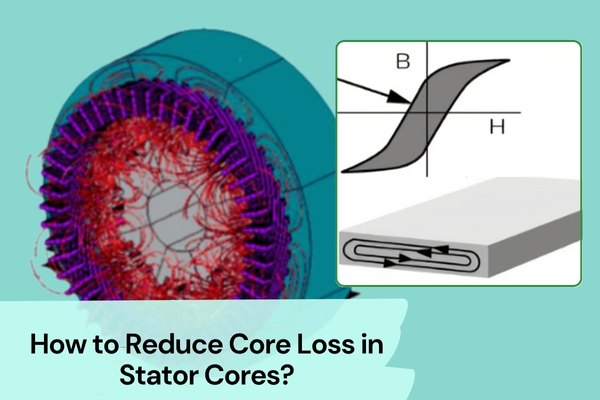

Silicon steel is the most commonly used material for transformer cores due to its exceptional magnetic properties. This material, also known as electrical steel, is highly efficient at conducting magnetic fields, which makes it ideal for reducing energy losses in transformers. Silicon is added to the steel to improve its resistivity and reduce eddy currents, enhancing the overall efficiency of the transformer.

Key Advantages of Silicon Steel Core

1. Silicon steel has high magnetic permeability, which is beyond doubt, but this alone is not enough.

2. Low iron loss. Electrical steel is much lower than other materials. This is one of the main reasons why silicon steel sheets have become transformer core materials.

3. Good hysteresis performance. It can shake quickly under the action of the magnetic field, so the hysteresis loss is much smaller than in other materials.

4. Silicon steel has good corrosion resistance and has high corrosion resistance to some chemical external environments.

5. The material cost is moderate. Although the price of silicon steel sheets is relatively high, considering its excellent performance and long service life, its cost-effectiveness is still very high.

6. Electrical steel has a certain mechanical strength and can support the windings and other components of the transformer.

Applications of Silicon Steel:

Silicon steel lamination is widely used in power transformers, distribution transformers, and small appliances.

Power Transformers: Commonly used in medium and large power transformers due to their ability to handle high magnetic fields and reduce core losses.

Distribution Transformers: Ideal for applications with less critical size and weight constraints, offering efficient performance in smaller-scale energy distribution.

The material is available in different grades, with grain-oriented (GO) and non-grain-oriented (NGO) silicon steel being the most common. Grain-oriented silicon steel is preferred for high-efficiency power transformers, while non-grain-oriented steel is often used in rotating machines and smaller transformers.

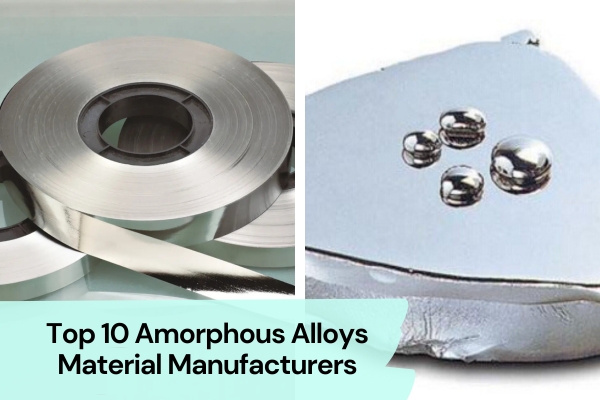

2. Amorphous Alloys: Energy-Efficient Transformer Core Material

Amorphous alloys are another material used for transformer cores. Unlike silicon steel laminated cores, amorphous transformer cores have a three-dimensional wound core structure.

Amorphous alloy is a new energy-saving material. It is primarily made from iron, nickel, cobalt, chromium, manganese, and other metals, with small amounts of boron, carbon, silicon, and phosphorus added. This composition gives it excellent ferromagnetic properties.

Typically, we use rapid solidification to produce amorphous alloy strips. The alloy melt is quickly cooled at a rate of millions of degrees per second, forming thin strips around 0.03mm thick.

Its physical structure is characterized by a long-range disordered arrangement of metal atoms.

Amorphous alloys possess many unique properties, such as excellent magnetic properties, corrosion resistance, and wear resistance. They also have high strength, hardness, toughness, and high resistivity, along with good electromechanical coupling properties.

Use Cases for Amorphous Alloy Core Materials in Transformers

Amorphous alloys are commonly used in distribution transformers, especially where energy efficiency is critical. These materials are ideal for transformers in renewable energy systems, such as wind and solar power, where reducing losses is paramount.

3. Ferrite Core: A Lightweight Transformer Core Material

Ferrite core material is a ceramic compound made from iron oxide and other metallic elements. It is widely used in transformers due to its lightweight nature and excellent magnetic properties at high frequencies.

Characteristics of Ferrite Core Materials

High Magnetic Permeability – Effective at conducting magnetic fields, even at high frequencies.

Low Electrical Conductivity – Reduces eddy current losses and heat generation.

Lightweight – Much lighter than metal cores, making it ideal for compact transformers.

Applications of Ferrite Cores

Ferrite cores are commonly used in small transformers, such as those found in electronic devices, switch-mode power supplies, and high-frequency transformers. Their lightweight and efficient design makes them suitable for applications where space and weight are constraints.

4. Nanocrystalline Core: Advanced Transformer Core Materials for High Frequency

Nanocrystalline core materials are made from ultra-fine grains, typically less than 100 nanometers, which give them superior magnetic properties compared to conventional materials. These advanced cores are highly efficient at conducting magnetic fields, making them ideal for high-frequency transformers.

Benefits of Nanocrystalline Core Materials in High-Frequency Transformers:

Low Core Losses – Reduces both eddy currents and hysteresis losses, especially in high-frequency applications.

High Magnetic Permeability – Allows for efficient energy transfer, even at elevated frequencies.

Thermal Stability – Maintains performance under varying temperature conditions, ensuring long-term efficiency.

Compared to silicon steel and amorphous alloys, nanocrystalline cores offer better performance at high frequencies and lower losses, making them superior in certain high-performance applications.

Use of Nanocrystalline Cores in Specialized Transformers

Nanocrystalline cores are used in specialized transformers, such as those in high-frequency power supplies, inductors, and transformers for renewable energy systems, where high efficiency and low losses are critical.

Contact Lammotor to Make High-Quality Transformer Laminations

Choosing the right transformer core materials is crucial for optimizing transformer efficiency, reducing energy losses, and improving performance. Whether you need silicon steel, amorphous alloys, ferrite, or nanocrystalline cores, selecting the right material ensures that your transformers operate at peak efficiency.

At Lammotor, we specialize in manufacturing high-quality transformer core laminations tailored to meet your specific needs. With years of expertise in the field, we ensure precision, durability, and top-tier performance for every product. Contact Lammotor today to discuss your requirements and find the best core material solution for your transformers.