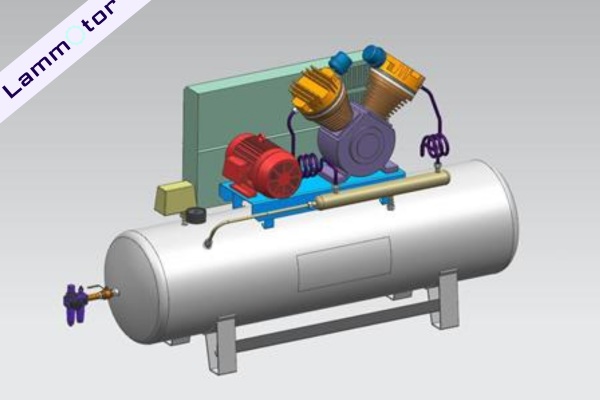

Are you trying to choose the right air compressor for your application but feeling overwhelmed by the different types available? Selecting the correct air compressor is crucial for efficiency, performance, and longevity in various industrial tasks. In this guide, we’ll break down the most common 6 types of air compressors, helping you understand their key features, advantages, and ideal uses.

To help you make an informed decision for your project, we have compiled 6 common types of air compressors.

Common air compressor types include the following:

Reciprocating Air Compressors(Piston Air Compressors )

Rotary Screw Air Compressors

Centrifugal Air Compressors

Axial Air Compressors

Rotary Scroll Air Compressors

Rotary Vane Air Compressors

1. Reciprocating Air Compressors

A reciprocating air compressor (piston compressor) is a type of positive displacement compressor where air is compressed by a piston moving back and forth within a cylinder. This motion increases the pressure of the air by reducing its volume.

Types of Reciprocating Air Compressors

Single-Acting Reciprocating Air Compressor: In this type, the piston compresses air on only one side during its stroke. It is commonly used in smaller, lower-demand applications.

Double-Acting Reciprocating Air Compressor: Here, the piston compresses air on both sides, making it more efficient and suitable for larger, continuous-duty applications.

Oil-Free Reciprocating Air Compressor: This type uses special materials to lubricate the piston, eliminating the need for oil. It’s ideal for applications requiring clean, contaminant-free air.

Applications of Reciprocating Air Compressors

Reciprocating compressors are widely used in industries such as automotive repair, manufacturing, and construction, where high pressure and intermittent duty cycles are required. They are also common in smaller workshops and garages.

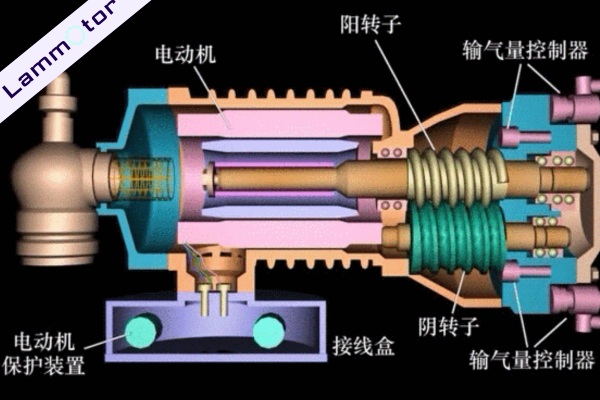

2. Rotary Screw Air Compressors

A rotary screw air compressor is a type of gas compressor that utilizes two helical screws (rotors) to compress air. These compressors are known for their continuous duty capabilities and high efficiency, making them ideal for demanding applications.

Types of Rotary Screw Air Compressors

Oil-Injected Rotary Screw Air Compressor: In this type, oil is injected into the compression chamber to cool and lubricate the rotors. This process improves efficiency and extends the compressor’s lifespan, making it suitable for heavy-duty industrial tasks.

Oil-Free Rotary Screw Air Compressor: This type avoids the use of oil in the compression chamber, using alternate methods to reduce heat. It’s ideal for applications requiring absolutely clean air, such as in the food, pharmaceutical, and electronics industries.

Advantages of Rotary Screw Air Compressors

Rotary screw air compressors offer continuous operation, low noise levels, and energy efficiency. They also require less maintenance compared to other types, making them a reliable choice for long-term use.

Common Uses of Rotary Screw Air Compressors

These compressors are widely used in industries such as manufacturing, automotive production, and large-scale construction projects, where a steady supply of compressed air is crucial for operational efficiency.

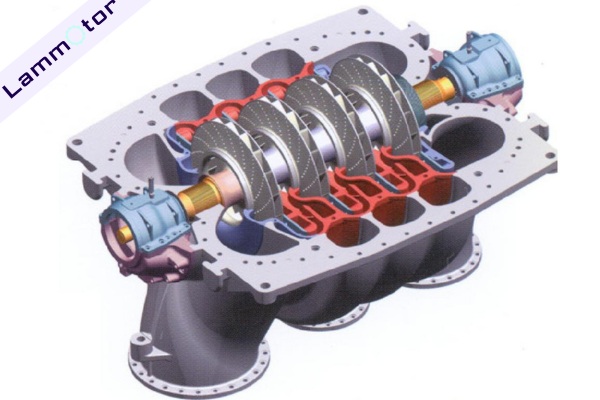

3. Centrifugal Air Compressors

A centrifugal air compressor is a dynamic compressor that uses a rotating impeller to accelerate and then decelerate air, converting kinetic energy into pressure. This type of compressor is known for delivering high volumes of air at a consistent pressure.

It works by drawing air into the center of a rotating impeller. The impeller accelerates the air outward, increasing its velocity. The air is then slowed down in a diffuser, where its kinetic energy is converted into pressure.

Benefits of Using Centrifugal Air Compressors

Centrifugal compressors offer high efficiency, reliable operation, and low maintenance. They are also capable of providing a constant flow of compressed air, making them ideal for continuous, high-volume applications.

Industrial Applications of Centrifugal Air Compressors

These compressors are commonly used in large-scale industrial settings such as chemical plants, oil refineries, and power stations, where consistent and large volumes of compressed air are required.

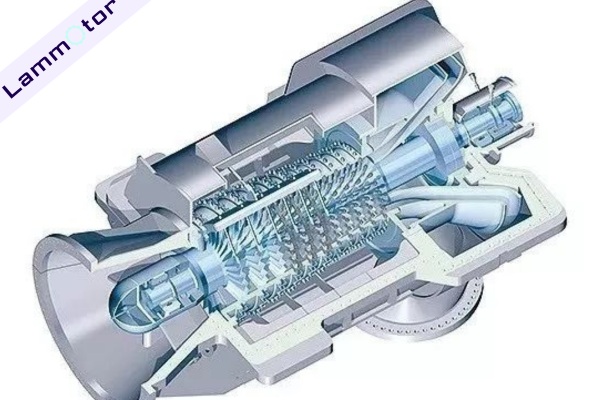

4. Axial Air Compressors

Axial air compressors are high-speed, dynamic compressors that are designed to produce large volumes of compressed air by utilizing a series of rotating and stationary blades.

It operates by accelerating air axially through a series of rotor blades, which then pass through stationary blades that increase pressure. This design allows for high efficiency and the ability to compress large volumes of air quickly.

Usage in High-Performance Applications

Due to their ability to manage large airflow rates, axial air compressors are primarily used in high-performance applications such as jet engines, gas turbines, and large-scale industrial processes where efficiency and high-speed operation are crucial.

5. Scroll Air Compressors

Scroll air compressors are a type of positive displacement compressor that uses two interleaved spiral scrolls to compress air. One scroll remains stationary, while the other orbits around it, trapping and compressing air in small pockets.

As the moving scroll orbits around the fixed scroll, the air is drawn into the compression chamber, gradually reducing in volume as it is moved toward the center of the scroll. This smooth and continuous motion results in a steady flow of compressed air.

Advantages of Scroll Air Compressors in Specific Applications

Scroll air compressors are highly efficient, quiet, and require minimal maintenance. They are ideal for applications requiring clean, oil-free air, such as in medical facilities, laboratories, and precision manufacturing environments.

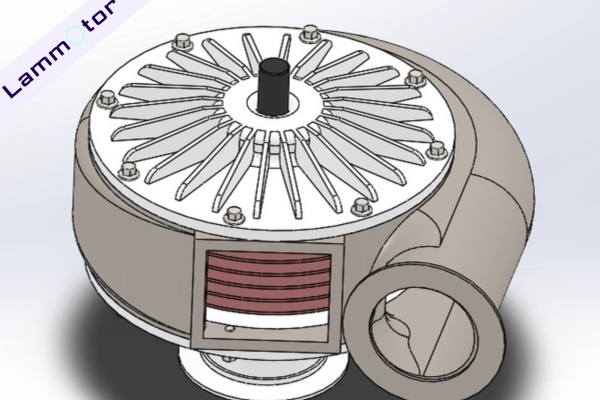

6. Rotary Vane Air Compressors

Rotary vane air compressors are a type of positive displacement compressor that utilizes a rotor with multiple vanes inserted into it. As the rotor spins, the vanes slide in and out, trapping and compressing air in the spaces between them.

Operational Principle of Rotary Vane Air Compressors

As the rotor turns, the vanes are pushed outward by centrifugal force, creating a seal against the compressor housing. The trapped air is then compressed as the volume of the chamber decreases, resulting in a steady flow of pressurized air.

Industries Where Vane Air Compressors Are Preferred

Rotary vane air compressors are favored in industries such as automotive, manufacturing, and food processing.

Choosing the Right Type of Air Compressor

Selecting the right air compressor depends on several key factors, including the specific requirements of your application, the environment in which the compressor will be used, and your budget.

Consider the air pressure and flow rate needed for your tasks—reciprocating compressors are ideal for high-pressure, intermittent use, while rotary screw compressors are better for continuous, heavy-duty applications.

If your work demands clean, oil-free air, oil-free rotary screw or scroll compressors are the best choices. Additionally, evaluate the maintenance needs and operational efficiency of each type.

By carefully matching the compressor type to your specific needs, you can ensure optimal performance, longevity, and cost-effectiveness for your operations.

Learn more from the air compressor motor core experts at Lammotor.

If you need air compressors motor core, contact Lammotor for a professional quote. We offer reliable solutions and high-quality motor cores to ensure the maximum performance and efficiency of your air compressors. Trust our expertise to help you make an informed decision.