Which motor adhesive manufacturers are truly shaping the motor industry?

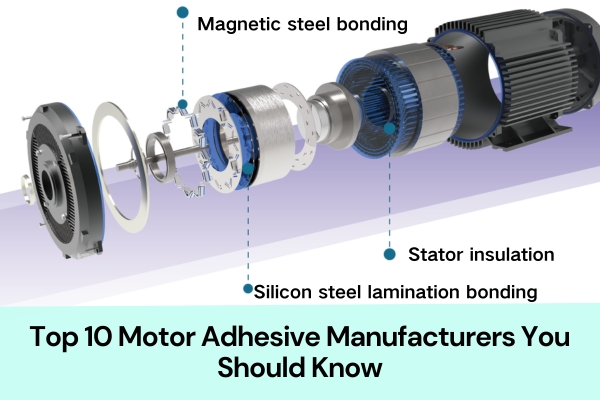

With rising demands for lightweight, high-efficiency, and heat-resistant electric motors—especially in EVs and industrial automation—adhesives have become critical components in manufacturing, not just auxiliary materials.

From magnet bonding and coil potting to thermal interface management and structural sealing, adhesives directly impact motor reliability, thermal stability, and production efficiency.

In this article, we break down 10 leading motor adhesive manufacturers whose products are already widely adopted across the industry.

Whether you’re working in motor design, procurement, or R&D, this guide gives you a clear picture of the proven brands used most frequently in real-world applications.

1. Loctite

Loctite, under Henkel, offers a comprehensive portfolio for every motor manufacturing stage:

- AA 326 + SF7649: Magnet bonding glue, 3-minute fixture time, 120°C resistance.

- EA 9588: Low-temperature curing at 80°C for pre-magnetized applications.

- EA 3335: UV-curing coil fixing adhesive, 20-second rapid positioning.

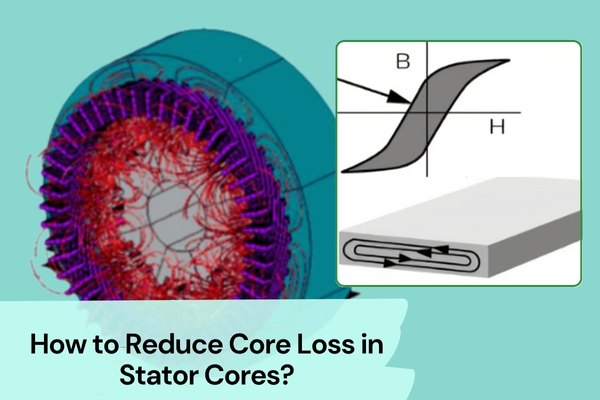

- LPD Series: Designed for silicon steel lamination impregnation, enhancing interlayer insulation.

2. 3M

3M specializes in optimizing electrical insulation systems, providing:

- Polyimide tapes (92 series): H-class high-temperature insulation.

- DMD/NMN flexible laminates: Slot and phase insulation for stator windings.

- DP420 / DP110 structural adhesives: For bonding magnets and end caps.

3. Dow

Dow’s DOWSIL™ and SILASTIC™ series cover multi-functional uses like thermal conductivity, sealing, shielding, and insulation:

- EC-8425 conductive adhesive: For inverter grounding, combining EMC and structural strength.

- Gap Filler series: Low thermal resistance materials for heat transfer.

- SILASTIC elastomers: Coil sealing with excellent thermal cycling durability.

4. Sika

The SikaBiresin® line focuses on high thermal conductivity and high dielectric strength potting materials:

- TC series: 1.2 W/m·K thermal conductivity, H-class heat resistance, available in fast-curing versions.

- RE series: Dielectric strength up to 24 kV/mm; low viscosity for vacuum impregnation. Supports insulation for 800V high-voltage platforms.

5. Permabond

Permabond offers fast-curing, high-temperature structural adhesives:

- TA439 / TA459: Withstands 200°C, shear strength 20–25 MPa, fixture in 20–40 seconds.

- TA437 + Initiator 41: Specially designed for pre-magnetized magnets.

- MS sealants: Solvent-free, moisture-cured, environmentally friendly, and oil-resistant.

6. Parker LORD

LORD adhesives provide both structural and functional bonding solutions:

- LORD 406-19 acrylic adhesive: Operates from -50°C to 150°C, 23–25 MPa shear strength.

- CHO-BOND 584-29: Conductive adhesive (resistivity: 0.005 Ω·cm), used in IGBT modules.

- Chemlok® Series: For rubber-to-metal bonding in vibration damping components.

7. Wacker

Wacker offers silicone-based materials for coil fixing, active cooling, and potting:

- ELASTOSIL® RT 7xx TC: Designed for hairpin winding encapsulation, 1.1 W/m·K thermal conductivity.

- POWERSIL TR 50: Silicone coolant alternative to glycol.

- SILRES H68 TC: Hydrophobic material for tight-gap impregnation.

8. Huitian

Chinese brand Huitian has achieved major performance improvements in magnet bonding:

- HT6066 epoxy adhesive: Shear strength 60 MPa, 180°C heat resistance, controlled bond line thickness (100 μm) to prevent delamination.

- Also developing high thermal conductivity adhesives for fast-charging cooling applications.

9. Beginor

Beginor provides a full series of adhesives for magnet bonding, electronic sealing, and stator encapsulation:

- EP 6112: UL94 V-0 flame-rated stator potting adhesive, heat-resistant up to 150°C.

- EP 621 New: High-Tg magnet adhesive, single-component paste.

- SICOAT 9060: Protective conformal coating with excellent dielectric properties.

10. Jointas

Jointas offers a closed-loop solution for structural bonding, housing sealing, and thermal management:

- ZS-GF-Z15 thermal grease: Wide temperature range (-40°C to 200°C), used for bearing cooling.

- Flame-retardant potting compounds: Support 800V high-voltage system protection.

The electric motor industry is shifting toward higher energy density, faster charging, and better thermal control. Choosing right motor adhesive manufacturers is not just about materials—it’s about optimizing your entire production system for safety, performance, and efficiency.

Which adhesive brand are you currently using? Have you considered upgrading your motor production with better bonding and insulation solutions?

Contact Us For Backlack/Bonding Motor Stator and Rotor Stacks

👉 If you’re looking for custom motor stator and rotor cores bonded with high-quality adhesives, we can help.

Our manufacturing capabilities cover prototyping to mass production, with options including bonded lamination stacks, encapsulated stators, and more.

Contact us today to get tailored adhesive motor core solutions for your application.