Are you trying to increase the motor slot fill factor but not sure where the real limits come from?

The motor slot fill factor is one of the most powerful tools we have when pushing power density, torque output, and efficiency. Small improvements often bring big gains. But to use it well, we must understand what controls it and how each design or process choice affects it.

In this article, I will walk you through the full picture—what the motor slot fill factor is, what affects it, and how we can raise it safely and effectively in real engineering work.

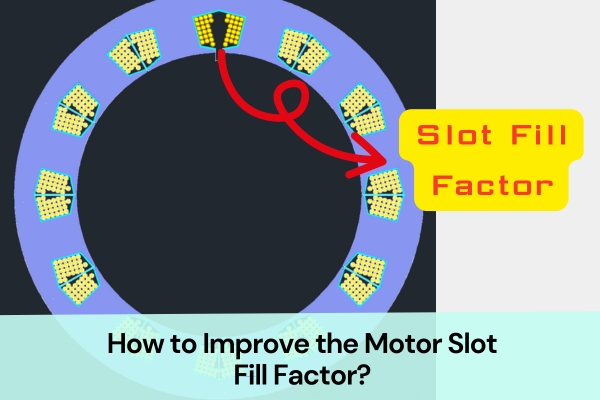

What Is the Motor Slot Fill Factor?

The motor slot fill factor describes the ratio between the total conductor area in a stator or rotor slot and the net usable slot area. It is usually expressed as a percentage.

Formula:

Slot Fill Factor Sf = (N × Sd × n) / As × 100%

N: total number of wires in the slot

Sd: cross-section area of one wire (including insulation)

n: number of wires in parallel

As: net usable slot area after removing insulation paper, wedges, liners, etc.

The higher the motor slot fill factor, the more copper we pack into the slot.

What Factors Affect the Motor Slot Fill Factor?

Before we improve the fill factor, we must understand what limits it. In general, the main factors fall into three groups: design and material, winding process, and electromagnetic constraints.

In real projects, different lamination structures and winding methods can also result in very different slot fill levels—even with the same slot shape and wire size.

1. Design and Material Factors

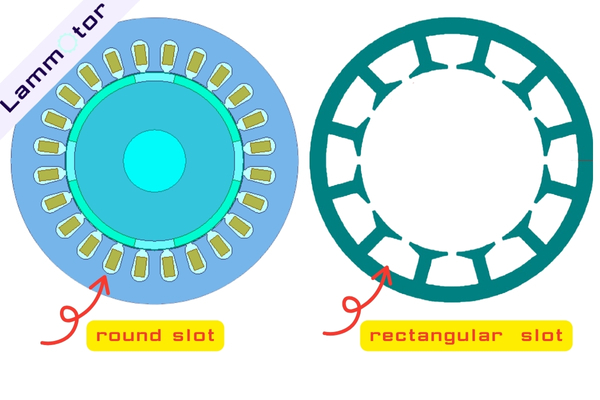

(1). Slot Shape Design

Round slots, pear-shaped slots, rectangular slots…

The slot geometry sets the upper limit for space use. The closer the shape is to a rectangle, the better the usable area. More rounded edges or transitions reduce usable copper area.

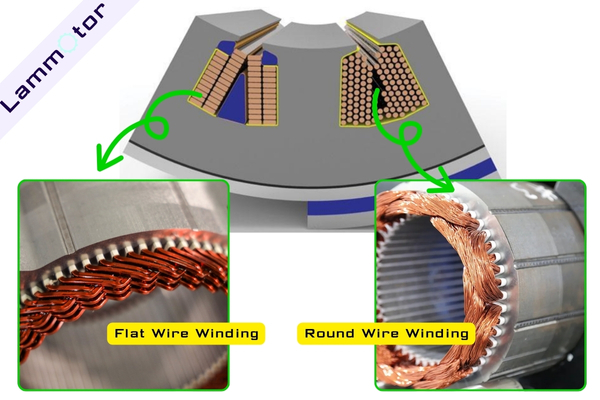

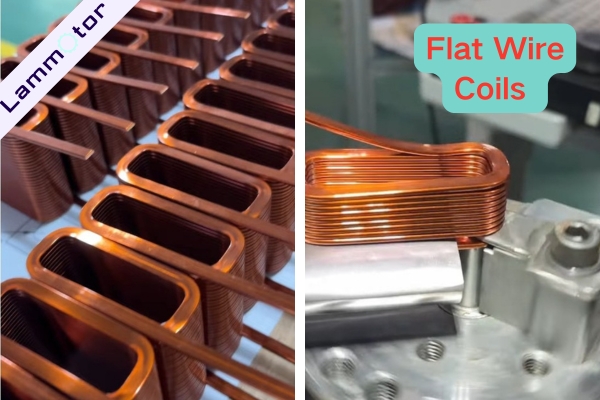

(2). Wire Type

Round wires naturally create gaps, which limits the motor slot fill factor.

Flat copper wires (Hair-pin or flat-wire winding) can stack tightly and greatly improve copper fill. They are now the main choice for high-fill EV motors.

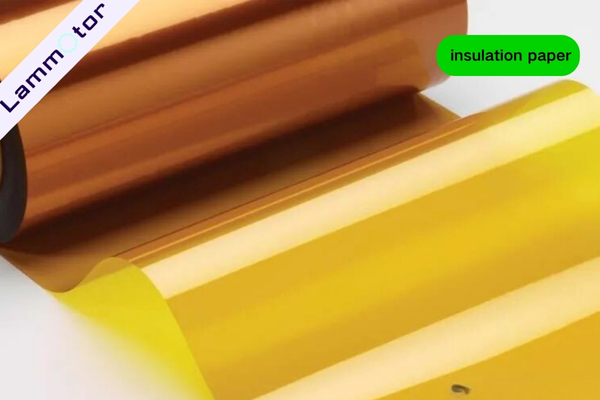

(3). Insulation Thickness

Slot insulation paper, wedges, and phase insulation all take up space.

Using thinner and stronger composite insulation materials such as DMD or NMN can noticeably increase the usable slot area As.

(4). Wire Coating Thickness

If the required voltage level allows it, choosing thinner coating types like UEW or AIW reduces Sd and creates more space for copper inside the same slot.

2. Winding Process Factors

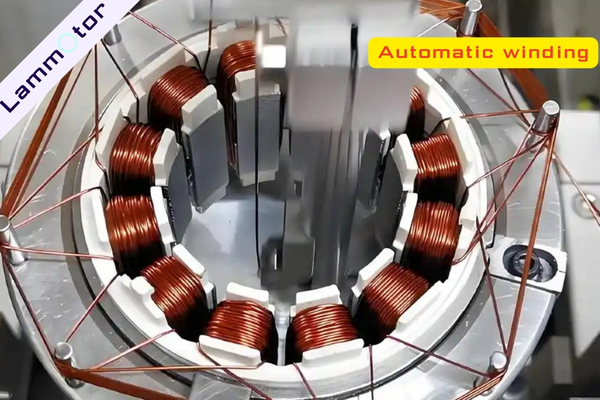

(1). Winding Method

Hand winding is loose and inconsistent.

Semi-automatic winding improves this.

Automatic winding creates neat, tight, and repeatable wire layouts, which is key to raising the motor slot fill factor.

(2). Coil Insertion

Skilled operators or automatic insertion machines can place multi-strand wires more tightly and evenly, reducing gaps inside the slot.

3. Electromagnetic Factors

(1). Slot Opening Size

A narrower slot opening may give a higher motor slot fill factor, but it also makes coil insertion harder or even impossible.

We must balance electromagnetic performance, manufacturing feasibility, and cost during design.

4. Stator Lamination Manufacturing Factors

Different lamination structures have a huge impact on the motor slot fill factor. Even with the same slot and wire, the fill level may differ by 10–25%.

(1). Full-Ring Stamping (Traditional One-Piece Stator Core)

This is the most common structure for small and medium motors.

Machine winding has a higher fill than random hand winding

Automatic winding keeps the coils consistent and tighter.

But this structure has a key limitation: a 2.5–5 mm wire-lead passage must be reserved

This is critical.

Because the slot is closed, the wire must enter the slot from the outside. For small slot widths, this passage area can significantly reduce usable copper fill.

Typical fill level: medium

One-piece stators rarely reach very high motor slot fill factor levels because:

- The wire-lead passage takes up space

- Wire bundles must pass through the narrow slot opening

- Coil insertion is structurally restricted

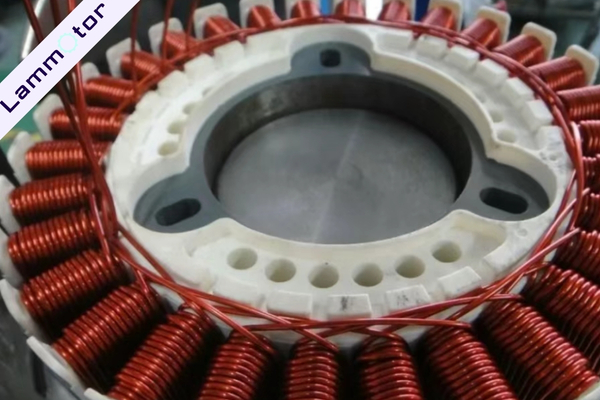

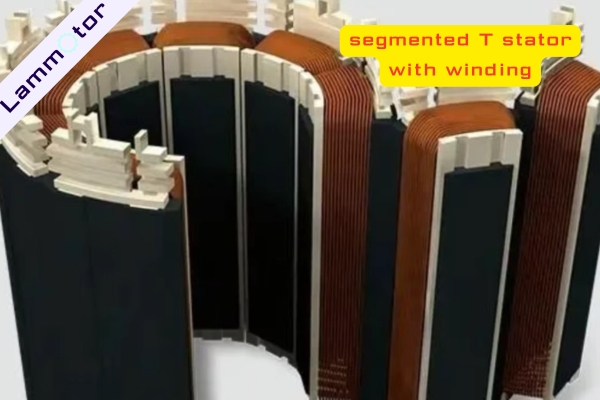

2. T-Segmented Stator (Segmented Stator Structure)

This structure is now widely used in EV drive motors and high-speed motors.

Main Advantages

- Easy winding

Each T-segment is wound independently, without slot-opening limits.

- High automation capability

Suitable for automatic winding and insertion.

- Maximum space use

The wound coils slide directly onto the segment; no lead-passage area is needed.

- Structural Features

- No need to reserve process space

- Wire can fully occupy the slot

- Motor slot fill factor is much higher than traditional one-piece cores

This is one of the most effective ways to boost the motor slot fill factor today.

How to Improve the Slot Fill Factor?

Now let’s look at practical engineering methods.

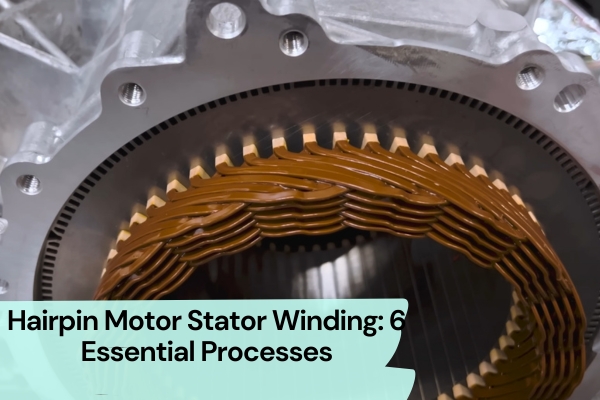

1. Use Flat Copper Wire (Hair-pin / Pin-wave)

This is the most direct and effective way.

Flat wire makes space use far better. The motor slot fill factor can easily exceed 70%, sometimes 80%, while round-wire motors often stay at 40–60%.

For EV motors, flat wire is almost standard.

2. Optimize Slot Shape and Slot Opening

Use FEM tools and remove internal “dead corners” while keeping:

- Proper magnetic flux

- Enough tooth strength

- A slot opening that still allows insertion

A good slot shape often boosts fill factor by 3–8%.

3. Use Thinner or Better Insulation Materials

DMD or NMN composite materials offer strong insulation with lower thickness.

Thin-coating magnet wires also increase usable space.

4. Improve Winding and Insertion Processes

- Automatic winding + automatic insertion gives the tightest and most uniform fill

- “Wire compaction” or pre-twisting reduces gaps in multi-strand bundles

- Using more strands of thinner wires sometimes fills corner spaces more efficiently

Impact of Higher Motor Slot Fill Factor

The motor slot fill factor is a double-edged sword. Higher fill improves performance, but also raises technical difficulty.

Positive Effects

- Higher power and torque density

More copper reduces resistance, cuts copper loss, and boosts output.

- Better cooling

Copper conducts heat far better than air, lowering hotspot temperature.

- Improved mechanical stability

Tightly packed coils resist vibration and reduce noise.

Potential Risks

- Harder coil insertion

Too high a fill factor increases the chance of scratching wire insulation, causing turn-to-turn shorts.

- Higher cost

Flat wire, thin insulation, and precision equipment increase manufacturing cost.

Contact Us for Stator Winding Services

Improving the motor slot fill factor is one of the most effective ways to boost a motor’s performance. If you are designing a new motor or want to raise the output of an existing one, start by looking at the slot fill. Many times, the gains are bigger than expected.

If you want help reviewing your slot design, winding process, or material options, feel free to contact us. We can support you with motor stator winding, segmented stator manufacturing, and high-fill winding solutions.

👉 Contact us today to manufacture your stator with professional winding services.