Generator Stator and Rotor Laminations in China

We manufacture large generator stator and rotor laminations, complete stator and rotor cores, and die-cast rotors for various types of generators. including nuclear, wind, hydro, and thermal power, as well as high-, medium-, and low-voltage AC motors, traction motors, high-efficiency permanent magnet motors, explosion-proof motors, and DC motors.

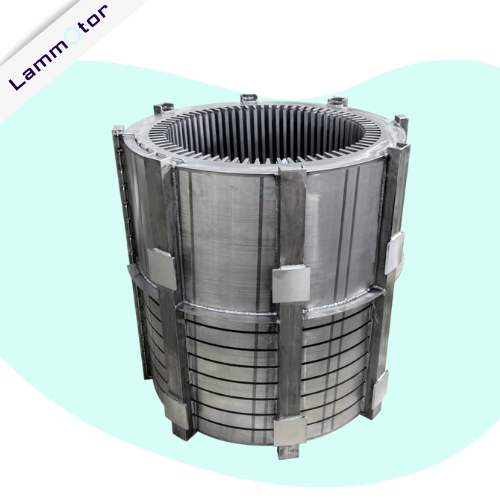

Generator Stator and Rotor Cores for Wind & Hydraulic Power

Lammotor specializes in the manufacturing of electrical steel sheets, laminated stator cores and rotor core components for large generators. We offer various specifications and sizes of laminations to meet your business needs.

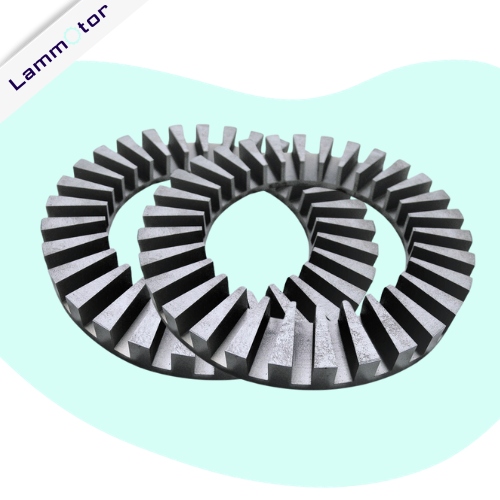

generator rotor lamination

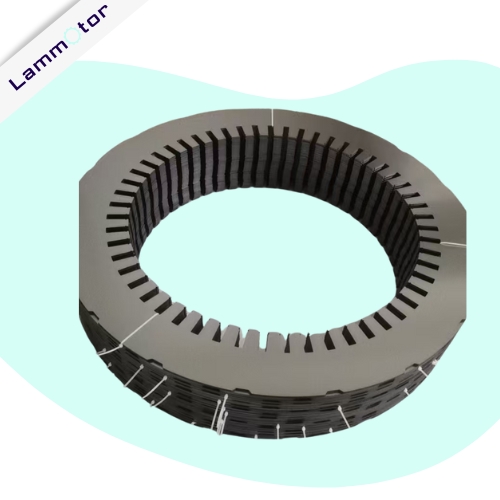

generator stator laminations

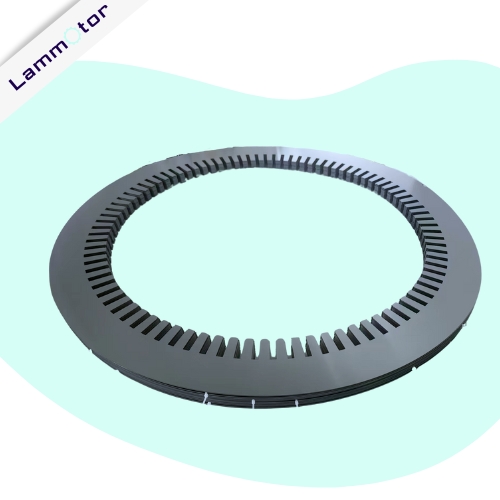

segmented stator laminations

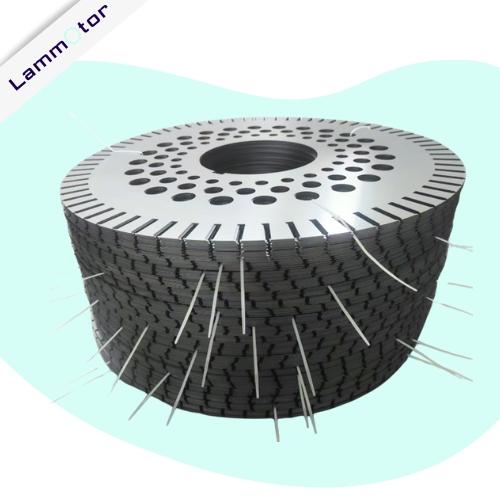

wind power generator stator stacks

generator stator core

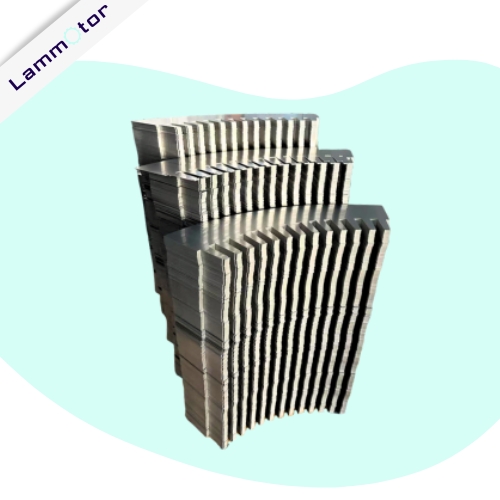

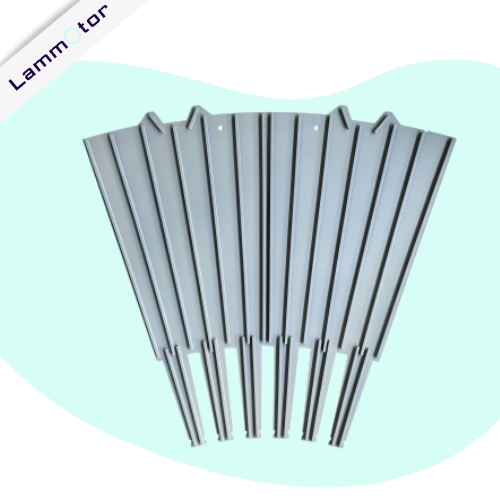

vent plate

Wind turbine generator stator lamination

wind power generator rotor stacks

Manufacturing Capabilities for Generator Laminations

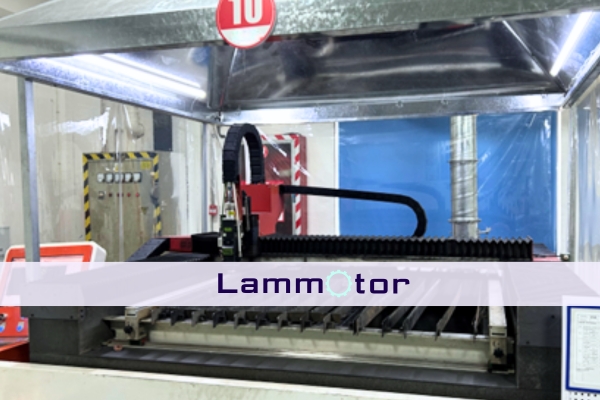

Laser Cutting Generator Stator and rotor Laminations

Laser cutting is for Prototypes and Small Volume generator stator and rotor laminations.

We can quickly respond to customer needs and deliver cores within 3-10 days, reducing R&D cycles. Also, we can stack the stator and rotor laminations by welding.

- Maximum processing capacity: 1100 x 1100 mm

- Laser cutting machines: 9 units

Stamping for Generator Laminations

Compound stamping and single slot stamping is for Mass Production wind power generator laminations.

We have over 500 sets of stamping molds, all molds are designed by ourselves. We have more than 20 stamping machines, and the max tonnage is 630T. The max outer diameter that can be stamped is around 850mm, depending on the slot type.

For single slot stamping, we can do the max stator outer diameter is 1200mm, if more than 1200mm, we will design it in a segmented lamination.

- Reverse Engineered Drawings: Send us stator or rotor samples, and we will create precise drawings through reverse engineering.

- Stator and Rotor Lamination Manufacturing: We manufacture generator stator and rotor laminations using laser cutting, compound stamping, and single-slot stamping.

- Vent Assemblies: Spot-welded and riveted vents, backup laminations, and coated plates. These ensure better cooling and longer generator life.

- Stator and Rotor Core Stacking: We provide segmented and skewed lamination stacking with custom tooling. This guarantees tight tolerances and stable stator and rotor cores.

- Welding: Fully automated welding lines and advanced gas-shielded arc welding.

- CNC Lathe Machining for precise outer diameter finishing.

- Aluminum Die Casting and Centrifugal Die Casting

What Services We Provide For Generators

Our generator cores enhance energy conversion efficiency in wind and hydro power, ensuring reliable and sustainable electricity generation across multiple applications.

Other Products

Request Information About Our Generator Lamination Stacks Services

With more than 10 CNC laser machines, over 50 stamping presses, two lamination core coating lines, a high-tech QC laboratory, an experienced engineering team, and continued investment in automation, our company is the ideal partner for full-core, high-quality, and specification-driven generator projects.

In addition, we have advanced mold development and manufacturing capabilities, along with a wide range of standard tools, enabling us to deliver reliable laminations and cores from samples to full-scale production.

Contact us today to discuss your project, explore customization options, and experience the unmatched quality of our generator laminations.