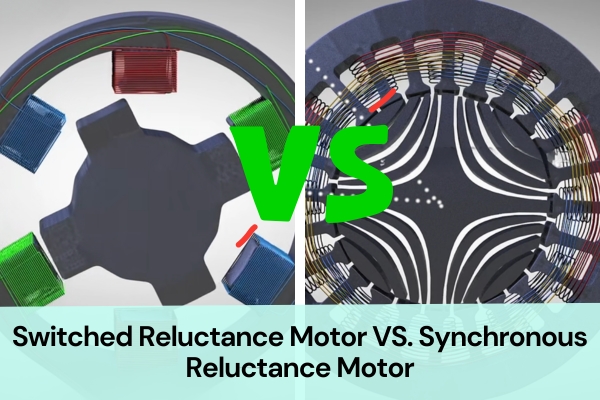

When choosing an electric motor, how do you decide which technology is best for your application? If you’ve heard about Switched Reluctance Motor VS. Synchronous Reluctance Motor but aren’t sure about the differences, you’re not alone.

Both motor types share the same fundamental principle—using magnetic reluctance to create torque—but their structures, control methods, and performance characteristics vary greatly. Understanding these differences can help you make the right choice for your project.

1. Switched Reluctance Motor (SRM)

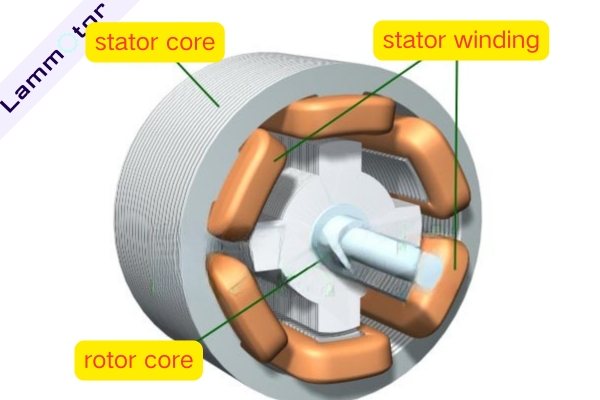

The Switched Reluctance Motor (SRM) is a type of DC motor with stator and rotor cores that both have salient poles. The stator uses concentrated windings, and the number of stator poles must be different from the rotor poles. A common design is the 6/4 configuration—six stator poles and four rotor poles.

The SRM requires a dedicated controller. It cannot run simply by applying power, nor can it be driven by a general-purpose inverter.

Structure of Switched Reluctance Motor – Double-Salient Pole Design

The switched reluctance motor stator core has six salient teeth, while the rotor core has four salient teeth. Both are made from laminated silicon steel sheets with good magnetic permeability. Like in other electric motors, there is a small air gap between the stator and rotor, allowing the rotor to rotate freely inside the stator.

Because both the stator and rotor have protruding poles, this design is called a double-salient pole structure. Coils are wound around the stator poles (stator windings), which act as the excitation windings to provide the working magnetic field for the motor.

A key feature of reluctance motors is that the rotor has no windings. In explaining how a typical motor works, it’s common to describe how a current-carrying conductor experiences force in a magnetic field. However, in a reluctance motor, the rotor has neither coils nor a squirrel cage. So, what drives the rotor to turn?

It works on the principle of minimum reluctance—magnetic flux always follows the path of least resistance. The magnetic attraction between the aligned poles of the stator and rotor pulls the rotor into position, producing rotation.

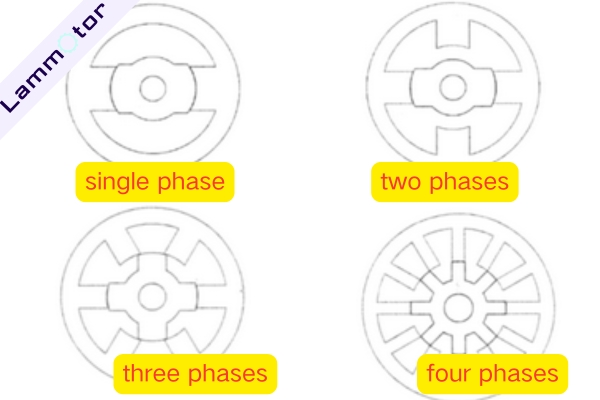

Switched reluctance motors can be single-phase, two-phase, three-phase, or four-phase. More phases mean smaller step angles and reduced torque ripple, but they also make the structure more complex, require more switching devices, and increase cost.

The three-phase SR motor is the most common design. It is the simplest structure that can self-start in both forward and reverse directions.

In a three-phase 6/8-pole rotor, the step angle is smaller than in a 6/4-pole design, which helps reduce torque ripple. However, it also lowers the inductance ratio between aligned and unaligned positions, which increases the controller’s VA capacity. Higher switching frequency in this configuration also raises core losses.

Advantages of SRM:

- No permanent magnets – No reliance on rare earth materials, making it more sustainable and cost-effective.

- No demagnetization risk – Better high-temperature tolerance and overload capability compared to permanent magnet motors.

- Lower core losses with advanced materials – Can use high-permeability amorphous alloys to improve efficiency and reduce heat.

- Simple rotor structure – Higher reliability, minimal maintenance, and a service life exceeding 10 years.

Disadvantages of SRM:

- High torque ripple

- Non-linear torque characteristics

- Higher vibration and noise

- Requires rotor position sensors and closed-loop control

- Large size for high torque applications

2. Synchronous Reluctance Motor (SynRM)

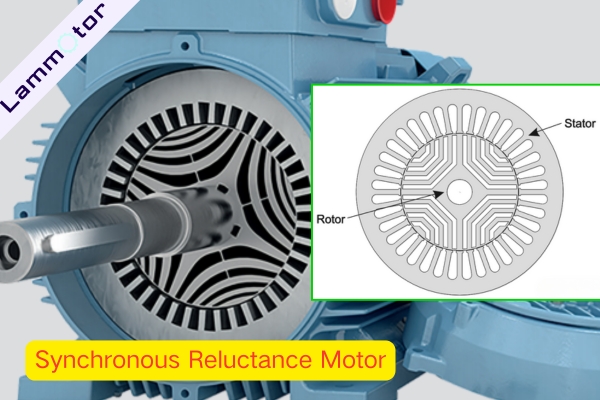

The Synchronous Reluctance Motor is also a magnet-free motor, relying entirely on reluctance torque without using Lorentz force.

Its rotor design is similar to an interior permanent magnet synchronous motor (IPMSM) but without magnets. Torque is generated by the difference in magnetic reluctance between the rotor’s direct axis (d-axis) and quadrature axis (q-axis).

The stator is typically the same as that of an induction motor, with the main differences in the rotor. The rotor has no magnets and no windings, and follows the same minimum reluctance principle as the SRM.

Rotor Types:

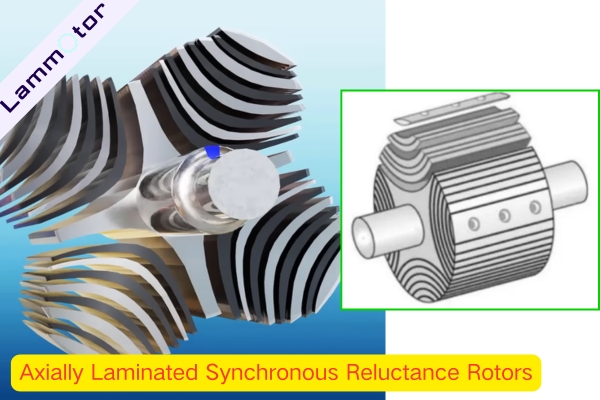

Axially laminated rotors

Made by alternately stacking layers of magnetic and insulating material along the shaft axis. They deliver high power factor and good performance but are complex and costly to manufacture, making them unsuitable for mass production.

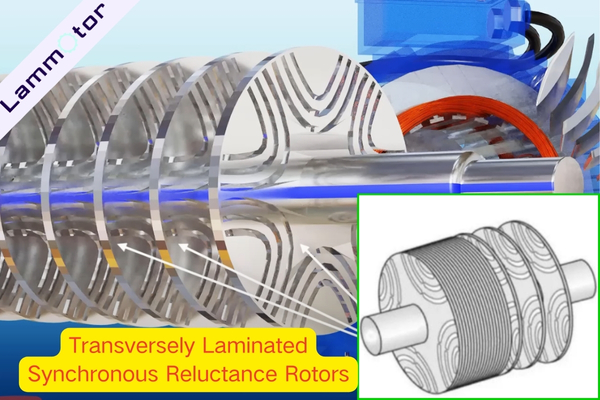

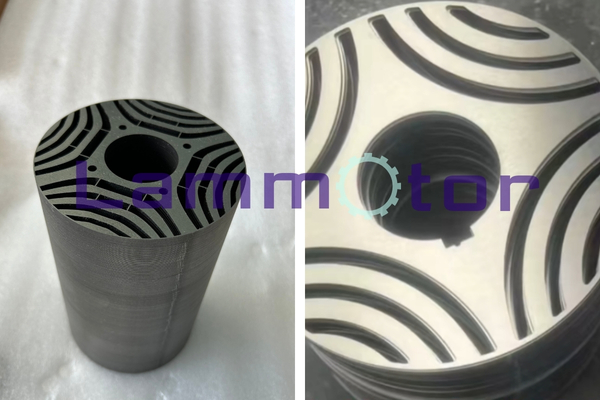

Transversely laminated rotors

Made by punching magnetic barriers into steel sheets and stacking them. This design is easier to manufacture, has high mechanical strength, and is more suitable for industrial applications.

Advantages of SynRM:

- Optimized magnetic path design using multiple magnetic barriers for high reluctance torque.

- Runs synchronously with the stator field—no slip losses.

- Magnet-free design reduces material cost by over 30% and eliminates demagnetization risks.

Disadvantages of SynRM:

- Lower market awareness and adoption compared to other motor types.

- Requires advanced motor control technology.

SynRMs are increasingly used to replace induction motors in applications like HVAC pumps and compressors. Companies like ABB have launched SynRM series motors with higher efficiency and power density, making them a reliable, energy-saving choice for various industries.

Summary – Switched Reluctance Motor VS. Synchronous Reluctance Motor

Both SRM and SynRM avoid the use of rare earth magnets, making them cost-effective and environmentally friendly.

SRMs are simpler in structure and robust in extreme conditions, while SynRMs offer smoother operation, higher efficiency, and better power factor.

When deciding between Switched Reluctance Motor VS. Synchronous Reluctance Motor, consider your priorities—cost, torque ripple, control complexity, efficiency, and maintenance.

If you need rotor and stator cores for reluctance motors, we can help. Our manufacturing expertise covers motor lamination stacks, rotor core manufacturing, and custom stator core production for both SRM and SynRM designs.

📩 Contact us today to discuss your project and get a quote for your Synchronous reluctance motor stator and rotor core manufacturing needs.