If you’re sourcing motors for demanding environments — where heat, humidity, and vibration are constant challenges — then the quality of your stator insulation isn’t just important, it’s critical.

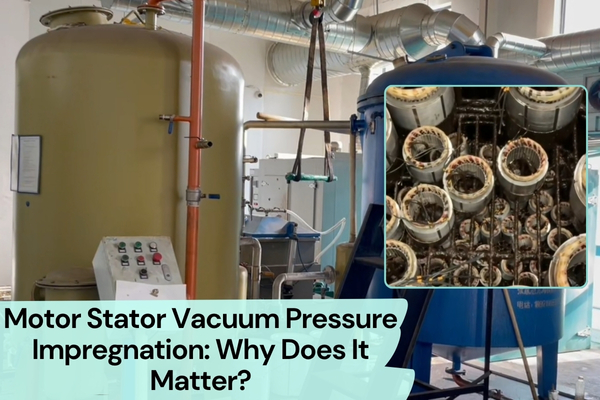

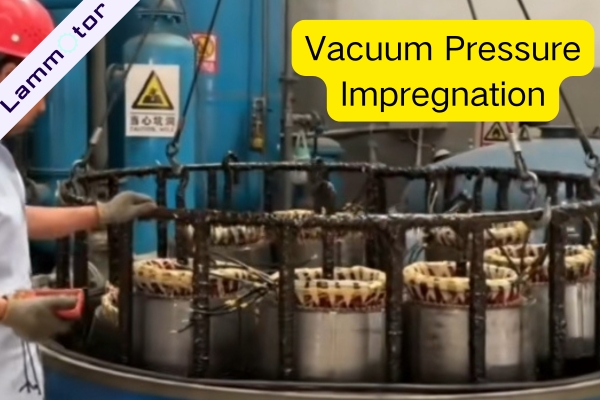

That’s why more and more customers are turning to Vacuum Pressure Impregnation (VPI).

Unlike traditional dipping methods, VPI delivers deep, uniform insulation that dramatically improves reliability, extends motor life, and reduces maintenance costs. But what exactly happens during the VPI process — and why is it considered the gold standard for stator windings?

As a manufacturer specializing in motor stator winding and insulation treatment, we’re here to break down the VPI process.

Manufacturing Process of Vacuum Pressure Impregnation

1. Pre-Baking and Dehumidification

Before the impregnation process begins, the stator is thoroughly dried in a constant-temperature oven to remove moisture, oil, and volatile substances. This ensures the varnish will fully penetrate the windings.

2. Loading into the VPI Tank

Once cooled, the stator is placed into the vacuum chamber of the VPI equipment. The chamber is sealed and readied for treatment.

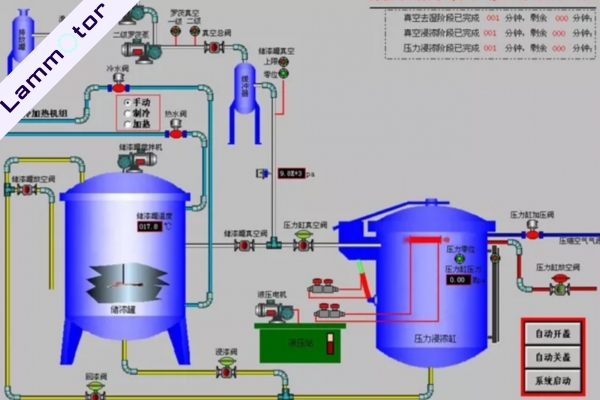

3. Vacuuming

A vacuum pump is used to evacuate the chamber to high vacuum levels, which also removes any air trapped inside the windings. This is key to preventing bubbles and voids during varnish filling. The vacuum is released, and pressure is applied for the resin or varnish to penetrate the voids in the part entirely.

4. Vacuum Impregnation

Insulation varnish is introduced into the chamber while maintaining vacuum pressure. The pressure difference helps draw varnish into every gap and crevice of the winding.

5. Pressure Impregnation

After full coverage, an inert gas (usually compressed air or nitrogen) is injected to raise the chamber pressure (typically 4–6 bar). This forces the varnish deeper into fine gaps, ensuring complete and thorough saturation.

6. Pressure Drainage

After maintaining pressure for a set period, the excess varnish is slowly drained. This prevents dripping and pooling, which could affect curing quality.

7. Decompression and Draining

The pressure is released gradually, and the stator remains in the tank to drip naturally, ensuring uniform varnish distribution on the surface.

8. Removal from Chamber

Once dripping is complete, the stator is removed from the chamber and prepared for curing.

9. Curing and Drying

The stator is baked at 120°C to 160°C for several hours to fully cure the insulation varnish. This cross-linking reaction forms a strong insulating layer that improves electrical performance, mechanical strength, and heat resistance.

Why Use Vacuum Pressure Impregnation? — Main Advantages

Compared to traditional varnish methods, VPI offers several key benefits:

1. Superior Insulation Performance

The vacuum stage removes all air pockets, allowing the varnish to fill every tiny gap. This results in a dense, bubble-free insulation layer with excellent dielectric properties.

2. High Resistance to Heat, Moisture, and Vibration

VPI-treated stators perform better in harsh environments such as high temperatures, humidity, or vibration — making them ideal for wind turbines, rail transit, and mining motors.

3. Uniform and Dense Insulation Layer

The combined vacuum and pressure stages ensure the windings are fully coated, reducing issues like corona discharge and partial discharge.

4. Longer Motor Lifespan

Stronger insulation translates to fewer breakdowns, less maintenance, and higher reliability — especially for large or mission-critical motors.

Vacuum Pressure Impregnation Process Parameters for Different Motor Coil Types

| Application | Vacuum (mmHg, time min) | Pressure (MPa, time min) |

| DC armature coil | 720 (5–10) | 0.2 (15–30) |

| AC/DC field coil | 720 (10–15) | 0.2 (60–75) |

| Low-voltage AC stator | 720 (15–20) | 0.2 (60–90) |

| DC motor winding | 720 (15–20) | 0.2 (60–120) |

| Moisture-resistant DC coils | 740 (5–10) | 0.7–0.8 (120–180) |

Other Common Impregnation Methods

While VPI is widely adopted, several other varnish techniques are still used for small or special applications. Here’s an overview:

1. Pouring Impregnation

Used mostly for small motor repairs. The stator is placed vertically, and varnish is poured manually over one end until it seeps through. The stator is then flipped, and the process is repeated.

Pros: Simple, cost-effective

Cons: Low efficiency, not suitable for batch production

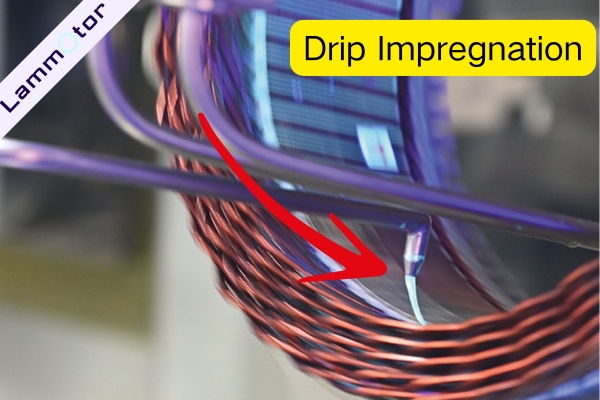

2. Drip Impregnation

Popular among small workshops without dedicated equipment. The stator is preheated (100–115°C), and varnish is dripped slowly onto the winding. It is then cured by heating (100–150°C) until insulation resistance reaches acceptable levels.

Pros: Practical and low-cost

Cons: Uneven varnish coating, less insulation control

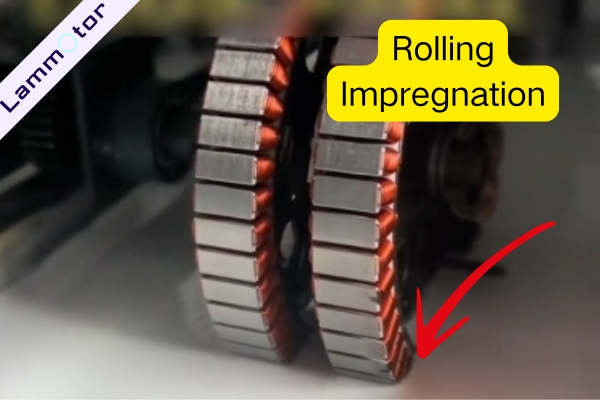

3. Rolling Impregnation

Common for medium-sized motors. The stator or rotor is rotated inside a varnish tank, ensuring full contact with the liquid. Manual brushing can help for shallow tanks.

Pros: Good penetration, supports batch production

Cons: Requires some equipment, not as versatile as VPI

4. Dipping Impregnation

The stator is fully submerged in varnish (minimum 200mm coverage). If pressure is applied (0.3–0.5 MPa), the effect is similar to a simplified VPI.

Pros: Efficient for mass production

Cons: Lower penetration depth than vacuum processes

| Method | Difficulty | Equipment | Penetration | Best Use |

| Pouring | ★ | Low | Low | Single repair, small motors |

| Drip | ★★ | Low | Medium | Small to mid-sized manual jobs |

| Rolling | ★★★ | Medium | Good | Medium-sized motors, batches |

| Dipping | ★★ | Medium | Medium | Batch production or repair |

| VPI | ★★★★★ | High | Excellent | High-voltage, large motors, wind power |

Contact Us for Motor Stator Winding

As a professional motor stator winding manufacturer, we tailor our insulation methods based on customer needs — whether it’s performance, budget, or operating environment. Among these methods, VPI stands out as the gold standard for insulation reliability and motor durability.

If you’re looking for a reliable partner to manufacture or treat motor stator windings with high-quality Vacuum Pressure Impregnation or other insulation techniques, feel free to contact us. Let’s find the best solution for your motor project together.