Choosing right amorphous alloy material manufacturers is key when looking for high-performance magnetic materials.

Amorphous alloys, also called metallic glass, offer excellent magnetic, electrical, and mechanical properties. They are widely used in power electronics, EVs, aerospace, and other high-tech fields.

So, who are the leading players in this space? Here’s a list of the top 10 amorphous alloy material manufacturers worldwide to help you better understand the industry.

If you would like to know about the amorphous core manufacturing process, please click this link.

1. Hitachi Metals, Ltd.

- Website: https://www.proterial.com/e/

- Founded: 1956 (formerly Hitachi Metals Industry Co., Ltd.)

- Location: Japan

Company Info:

Hitachi Metals is one of global leader in the amorphous alloy material manufacturers market. Since 1977, it has focused on soft magnetic amorphous alloy development. It acquired Metglas in 2003 and expanded cits apacity to 60,000 tons.

In 2006, Hitachi released the 2605HB1 series, later upgraded to HB1M in 2010. In 2021, it launched MaDC-ATM with 30% lower core loss.

The company also developed laminated amorphous cores made from SA1 or HB1M. These cores have better high-frequency properties than 6.5% Si steel.

Main Products: Amorphous ribbons (2605HB1, HB1M, MaDC-ATM), laminated amorphous cores

Applications: High-frequency transformers, power electronics, energy-saving equipment, renewable systems

2. Advanced Technology & Materials Co., Ltd. (ATM)

- Website: http://www.atmcn.com/

- Founded: 1998

- Location: Beijing, China

Company Info:

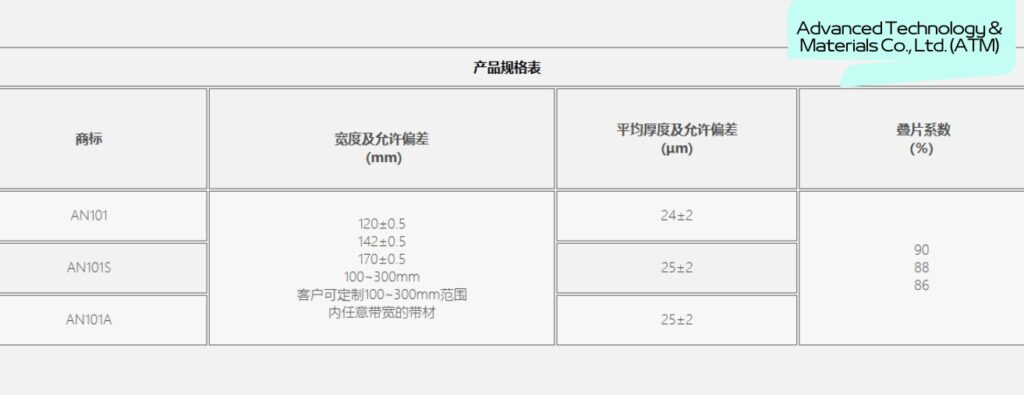

ATM focuses on advanced metal materials for strategic industries. It offers solutions in amorphous/nanocrystalline ribbons, refractory metals, powders, magnetic materials, welding materials, filters, and tool steels.

Main Products: Amorphous ribbons (AN101 series), nanocrystalline ribbons and cores, magnetic sheets

Alloy Grades: AN101, AN101S, AN101A

Applications: Aerospace, power electronics, EVs, manufacturing, consumer electronics

3. Qingdao Yunlu Advanced Materials Technology Co., Ltd.

- Website: https://www.yunluamt.com.cn/

- Founded: 2015

- Location: Qingdao, China

Company Info:

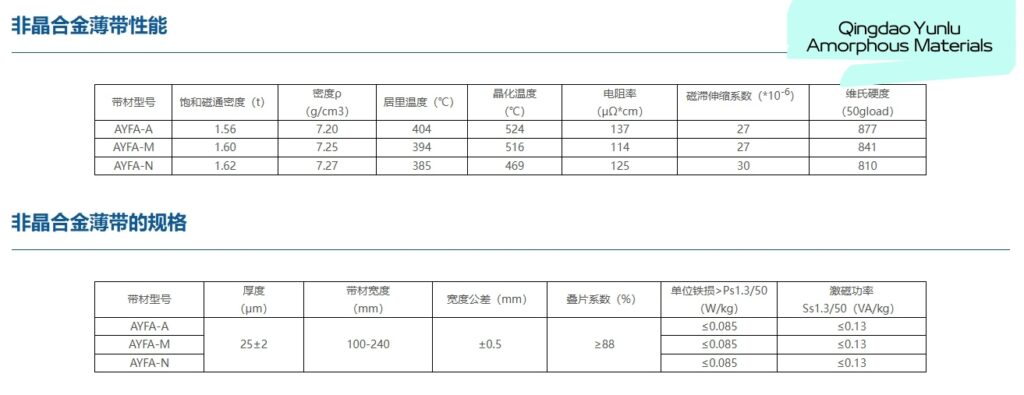

Yunlu focuses on magnetic metal materials. It develops and produces amorphous alloys, nanocrystalline alloys, and magnetic powders.

Main Products: AYFA series amorphous ribbons (AYFA-A, AYFA-M, AYFA-N)

Applications: Power distribution, EVs, wireless charging, nuclear power, medical, aerospace

4. VACUUMSCHMELZE GmbH (VAC)

- Website: https://www.vacuumschmelze.com/

- Founded: 1914

- Location: Germany

Company Info:

VAC is a global magnetic materials expert with deep experience in amorphous and nanocrystalline solutions.

VITROVAC® amorphous alloys are soft magnetically but hard mechanically. They have high magnetic flux density and excellent permeability.

VAC offers Fe-based and Co-based amorphous alloys.

Main Products: VITROVAC amorphous alloys

Alloy Grades: 6155 U55, 7600 T70, 6006 A10, 6025 G40, 6025 I50, 6030 D30

Applications: Sensors, antennas, shielding, transformers, aerospace, EVs

5. Henan Zhongyue Amorphous New Materials Co., Ltd.

- Website: Not publicly available

- Founded: 2010

- Location: Zhengzhou, China

Company Info:

Zhongyue is a national high-tech company and the fourth-largest amorphous and nanocrystalline supplier globally. Trusted by brands like BYD and Haier.

In 2020, it developed the ZYFJ-D amorphous ribbon and launched mass production of ultra-thin ribbons for wireless charging and flexible screens.

Main Products: Amorphous/nanocrystalline ribbons, cores, transformers, common-mode inductors

Applications: Solar, wind, hydropower, EVs, rail transport

6. Liquidmetal Technologies

- Website: https://liquidmetal.com/

- Founded: 1997

- Location: California, USA

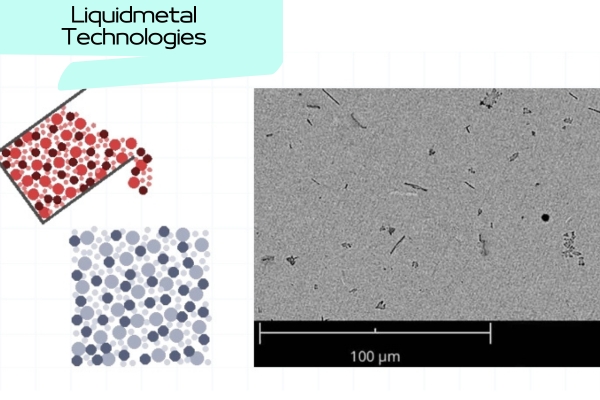

Company Info:

Liquidmetal is the first manufacturer of amorphous alloy material to commercialize bulk amorphous metals. It holds core patents in the field.

Apple licensed its technology exclusively in 2010 and used it in the iPhone 3G SIM ejector tool.

Main Products: High-strength bulk amorphous metal structures

Applications: Consumer electronics, medical, precision equipment

7. Eontec Co., Ltd. (Yeean Tech)

- Website: Not listed

- Founded: 2014

- Location: Dongguan, China

Company Info:

Eontec invested 300 million yuan to expand liquid metal production. It’s one of the few companies that achieved commercial use of amorphous alloy parts in electronics.

At CES 2015, it showcased an iPhone 6 Plus frame made from liquid metal.

Main Products: Liquid metal (amorphous) parts

Applications: Consumer electronics, smart devices

8. Changzhou Stream Liquid Metal Co., Ltd.

- Website: https://www.streammetal.com/

- Founded: 2014

- Location: Changzhou, China

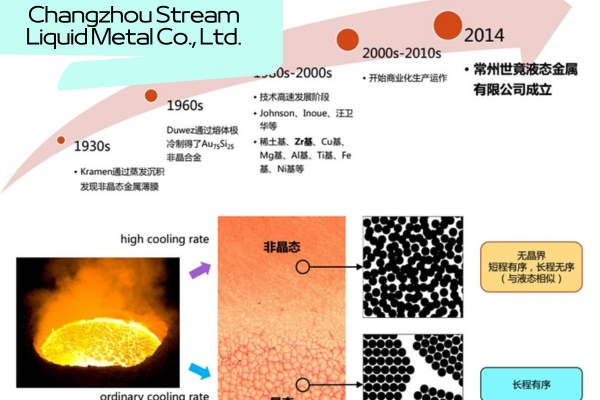

Company Info:

Stream is a high-tech firm that researches, makes, and sells liquid metal materials. It offers full solutions to clients in the electronics, medical, and smart equipment fields.

Main Products: Liquid metal materials and parts

Applications: Consumer electronics, smart devices, medical equipment

9. Dongguan PrometalTech Co., Ltd.

- Website: https://www.prometaltech.com/

- Founded: 2014

- Location: Dongguan, China

Company Info:

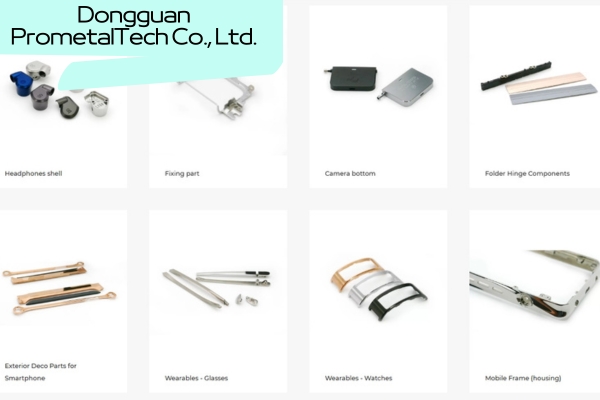

PrometalTech builds its own equipment for liquid metal production. It includes casting machines, CNC tools, and vacuum melting systems. The entire process is done in-house.

Main Products: Liquid metal parts, molding and casting equipment

Applications: Electronics, smart gear, luxury goods, sports, medical devices

10. Zhongyan Amorphous Technology Co., Ltd.

- Website: Not listed

- Founded: 2008

- Location: Foshan, China

Company Info:

Zhongyan focuses on amorphous/nanocrystalline materials and magnetic parts. Its products serve China’s key strategic industries.

Main Products: Fe-based and Co-based ribbons (e.g. 1K101, 1K201, 1K202), magnetic cores, sensors

Applications: IT, renewable energy, green tech, advanced manufacturing

Contact Us for Amorphous Alloys Cores

These amorphous alloy material manufacturers are shaping the future of materials science. Some are well-established giants, while others are fast-rising players.

Whether you’re making transformers, EVs, or electronics, these materials may already be part of your product.

If you’re looking for reliable amorphous alloy material manufacturers, take time to compare your options.

And if you need amorphous alloy cores, we at Lammotor can help! We provide custom core solutions—from material selection to lamination stacking. Contact us anytime to discuss your project. Let’s build something great together!